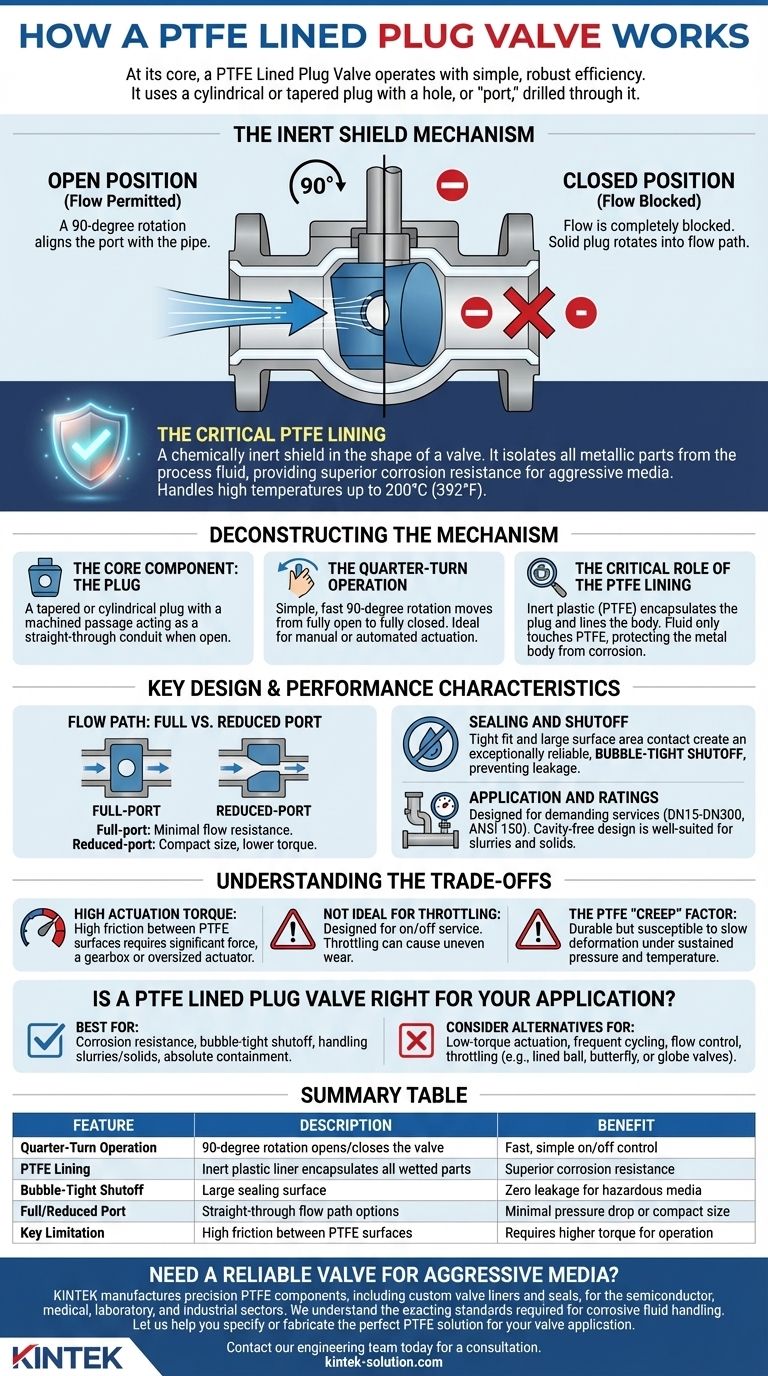

At its core, a PTFE Lined Plug Valve operates with simple, robust efficiency. It uses a cylindrical or tapered plug with a hole, or "port," drilled through it. When this port aligns with the pipe, flow is permitted; when a 90-degree turn rotates the solid part of the plug into the flow path, the flow is completely blocked. The critical feature is the Polytetrafluoroethylene (PTFE) liner, which isolates all metallic parts from the process fluid.

A PTFE Lined Plug Valve is essentially a chemically inert shield in the shape of a valve. It provides superior corrosion resistance for aggressive media using a simple quarter-turn mechanism, but this design requires managing the inherent trade-off of high operational torque.

Deconstructing the Mechanism

The valve's function is defined by the interaction between three key elements: the plug, the liner, and the quarter-turn operation. Understanding how they work together reveals the valve's core strengths.

The Core Component: The Plug

The central element is a plug, typically tapered, that fits snugly inside the valve body. A passage is machined through the plug. When the valve is open, this passage acts as a straight-through conduit for the fluid.

The Quarter-Turn Operation

This valve is a "quarter-turn" device. A 90-degree rotation of the stem is all that is needed to move from the fully open to the fully closed position. This makes actuation simple and fast, whether done manually or with an automated actuator.

The Critical Role of the PTFE Lining

The defining characteristic is the PTFE liner. This thick layer of inert plastic is locked into the valve body and completely encapsulates the plug.

Because the fluid only ever touches the PTFE, the metal valve body (typically cast steel or ductile iron) is protected from corrosion. This makes the valve ideal for handling highly aggressive chemicals like acids, bases, and solvents. The PTFE can also handle high temperatures, often up to 200°C (392°F).

Key Design and Performance Characteristics

Beyond the basic mechanism, the valve's specific design features dictate its performance in an industrial system. These details determine its suitability for different applications.

Flow Path: Full vs. Reduced Port

You will encounter both full-port and reduced-port designs. A full-port design has a flow path equal to the inner diameter of the connecting pipe, offering minimal flow resistance. A reduced-port design has a narrower path, which can increase friction but often reduces the valve's size and the torque needed to operate it.

Sealing and Shutoff

The tight fit and large surface area contact between the lined plug and the lined body create an exceptionally reliable seal. This design provides a bubble-tight shutoff, preventing any leakage when the valve is closed, which is critical for hazardous media.

Application and Ratings

These valves are designed for demanding services. They are commonly available in sizes from DN15 to DN300 (0.5" to 12") and pressure classes like ANSI 150. Their design, which lacks internal cavities where material can collect, makes them well-suited for slurries and fluids containing solids.

Understanding the Trade-offs

No valve design is without compromises. The strengths of the lined plug valve are balanced by specific limitations that are critical to consider during selection.

High Actuation Torque

The most significant challenge is high friction. The large, tight sealing surface between the PTFE on the plug and the PTFE on the body creates considerable resistance. This means a significant amount of force, or torque, is required to turn the plug, often necessitating a gearbox for manual operation or a powerful, oversized actuator.

Not Ideal for Throttling

A plug valve is designed primarily for on/off service. Using it in a partially open position to regulate flow (throttling) can cause uneven wear on the liner and plug, potentially compromising the integrity of the seal over time.

The PTFE "Creep" Factor

While durable, PTFE can be susceptible to "creep"—a slow deformation under sustained pressure and temperature. Proper valve design and adherence to pressure/temperature limits are essential to ensure the liner maintains its shape and sealing capability over the long term.

Is a PTFE Lined Plug Valve Right for Your Application?

Choosing the correct valve requires matching its inherent characteristics to your primary goal. Use this as a guide to make an informed decision.

- If your primary focus is corrosion resistance and bubble-tight shutoff: This valve is a leading choice, offering uncompromising protection against aggressive chemicals.

- If your primary focus is handling slurries or fluids with solids: The cavity-free, straight-through design makes it highly reliable and prevents clogging.

- If your primary focus is low-torque actuation or frequent cycling: The high friction is a major drawback; a lined ball or butterfly valve may be a more efficient option.

- If your primary focus is flow control and throttling: A different design, such as a lined globe valve, is purpose-built for regulation and will provide better performance and longevity.

Ultimately, the PTFE Lined Plug Valve excels in applications where absolute containment of corrosive or difficult media is the highest priority.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Quarter-Turn Operation | 90-degree rotation opens/closes the valve. | Fast, simple on/off control. |

| PTFE Lining | Inert plastic liner encapsulates all wetted parts. | Superior corrosion resistance against acids, bases, and solvents. |

| Bubble-Tight Shutoff | Large sealing surface between plug and body. | Zero leakage for hazardous media. |

| Full/Reduced Port | Straight-through flow path options. | Minimal pressure drop or compact size. |

| Key Limitation | High friction between PTFE surfaces. | Requires higher torque for operation. |

Need a Reliable Valve for Aggressive Media?

PTFE Lined Plug Valves are the benchmark for handling corrosive chemicals, slurries, and demanding processes where leak-proof performance is critical.

KINTEK manufactures precision PTFE components, including custom valve liners and seals, for the semiconductor, medical, laboratory, and industrial sectors. We understand the exacting standards required for corrosive fluid handling.

We offer:

- Custom Fabrication: From prototype development to high-volume production.

- Material Expertise: Ensuring optimal PTFE performance for your specific temperature and chemical exposure.

- Precision Production: Guaranteeing reliable, bubble-tight seals and consistent quality.

Let us help you specify or fabricate the perfect PTFE solution for your valve application.

Contact our engineering team today for a consultation on your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries commonly use PTFE sheets and for what purposes? Unlock the Power of High-Performance PTFE

- What are the mechanical, thermal, and electrical properties of PTFE sheets? The Ultimate Guide to Performance

- What are the key properties of Teflon bearings? Engineered for Extreme Environments

- Why are PTFE rotary shaft seals preferred in aggressive media? Superior Chemical Resistance & Reliability

- What are the recommended conditions for hardening bonded PTFE? Achieve a Strong, Stress-Free Bond

- Why is Teflon used in hoses? Ensuring Unmatched Reliability in Extreme Conditions

- How can PTFE's properties be enhanced? Boost Performance with Filled PTFE Composites

- What are the common uses of PTFE Lined Globe Valves? Essential for Corrosive & High-Purity Flow Control