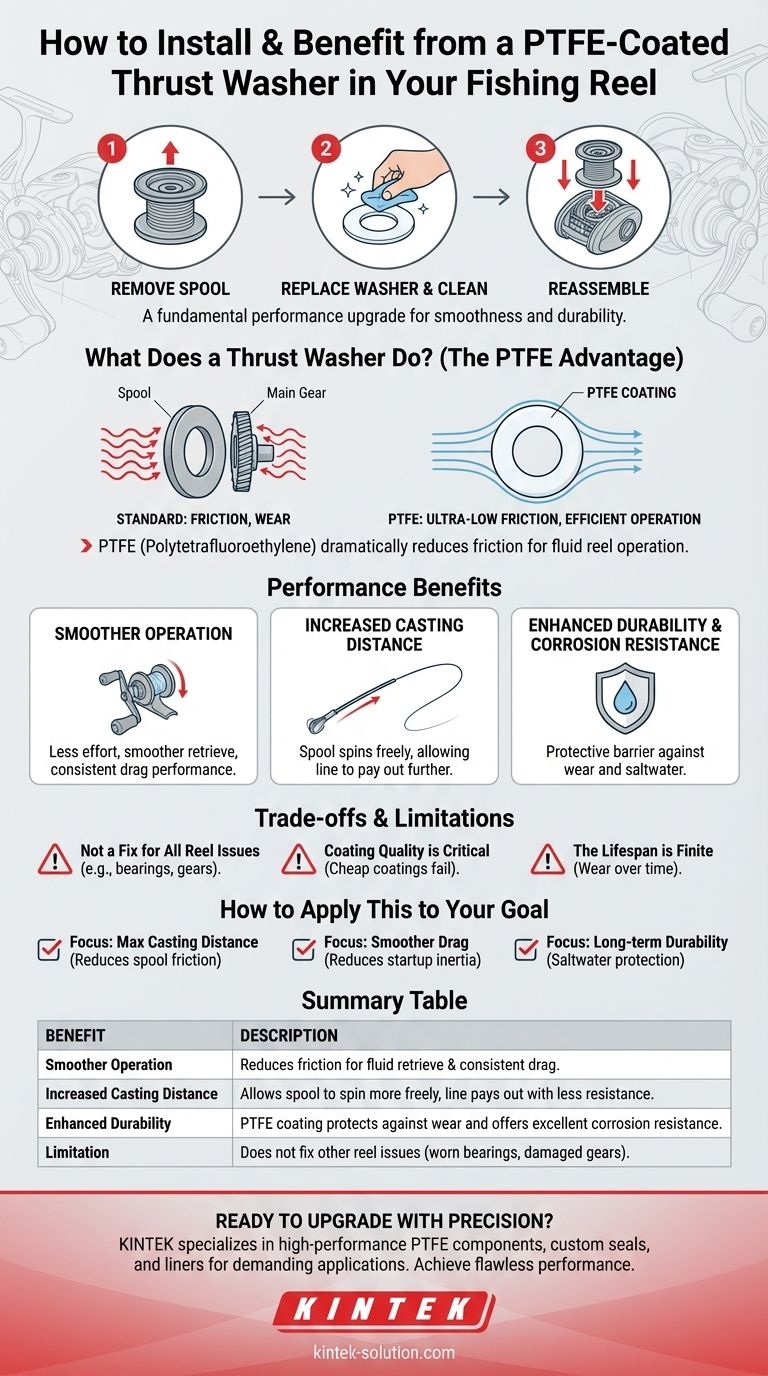

Installing a PTFE-coated thrust washer is a straightforward process that begins with removing the reel's spool. You then simply lift out the old washer, clean the surface where it sat, and place the new, coated washer in its place, ensuring it is seated flat before reassembling the reel.

This simple component swap is more than just a repair; it's a fundamental performance upgrade. By introducing a low-friction PTFE surface at a key contact point, you directly enhance the smoothness, durability, and even the casting distance of your fishing reel.

What Does a Thrust Washer Actually Do?

A thrust washer is a small but critical component designed to manage axial load—the force exerted along the axis of a shaft. In a fishing reel, it serves a very specific purpose.

The Role of a Standard Washer

A standard thrust washer sits between the spool and the main gear. Its job is to provide a smooth, sacrificial surface for these two parts to rotate against, preventing direct metal-on-metal wear.

The PTFE Advantage: Overcoming Friction

PTFE (Polytetrafluoroethylene) is a polymer known for its extremely low coefficient of friction. When applied as a coating to a thrust washer, it dramatically reduces the friction between the spool and the gear system.

This reduction in friction is the core principle behind the upgrade, leading to more efficient and fluid operation of the entire reel.

The Performance Benefits of a PTFE Upgrade

Replacing a standard washer with a PTFE-coated one delivers several tangible improvements that you can feel with every cast and retrieve.

Smoother Operation

The most immediate benefit is a noticeable increase in smoothness. The ultra-slick surface allows the spool to rotate with less effort, which translates to a smoother retrieve and a more consistent drag performance.

Increased Casting Distance

By reducing the friction the spool must overcome as it spins, a PTFE washer allows the line to pay out more freely during a cast. This can lead to a measurable increase in casting distance.

Enhanced Durability and Corrosion Resistance

The PTFE coating acts as a protective barrier. It prevents wear on critical components and offers excellent resistance to corrosion, making it an ideal upgrade for saltwater fishing where equipment is constantly exposed to harsh conditions.

Understanding the Trade-offs and Limitations

While a PTFE washer is an excellent upgrade, it's important to understand its context and limitations to set realistic expectations.

Not a Fix for All Reel Issues

This upgrade specifically targets friction at the thrust washer's location. It will not solve problems related to worn-out bearings, damaged gears, or a poorly maintained drag stack.

Coating Quality is Critical

The performance and longevity of the washer depend entirely on the quality of the PTFE coating and the manufacturing process. A cheap, poorly applied coating will wear out quickly and fail to deliver the promised benefits.

The Lifespan is Finite

Even high-quality coatings will eventually wear down. The lifespan of the washer is determined by the frequency of use, the loads it's under, and the operating conditions of the reel.

How to Apply This to Your Goal

Choosing to upgrade is about matching the component's benefits to your specific angling needs.

- If your primary focus is maximum casting distance: This is a key upgrade, as reducing spool friction allows the line to flow more freely.

- If your primary focus is a smoother, more consistent drag: A PTFE washer can reduce the "stickiness" or startup inertia in a drag system, leading to a more reliable fight.

- If your primary focus is long-term durability, especially in saltwater: The added corrosion resistance provides a tangible benefit that protects your investment in harsh environments.

This small, inexpensive component is one of the most effective ways to enhance the core performance of your reel.

Summary Table:

| Benefit | Description |

|---|---|

| Smoother Operation | Reduces friction for a more fluid retrieve and consistent drag. |

| Increased Casting Distance | Allows the spool to spin more freely, letting line pay out with less resistance. |

| Enhanced Durability | PTFE coating protects against wear and offers excellent corrosion resistance. |

| Limitation | Does not fix other reel issues like worn bearings or damaged gears. |

Ready to upgrade your reel's performance with precision-engineered components?

The quality of the PTFE coating is critical to achieving the smoothness, distance, and durability gains described in this article. KINTEK specializes in manufacturing high-performance PTFE components, including custom seals and liners, for demanding applications in the medical, semiconductor, and industrial sectors. Our expertise in precision production ensures a superior, long-lasting finish that cheaper alternatives can't match.

Let us help you achieve flawless performance. Contact KINTEK today to discuss custom fabrication for your specific needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Are Teflon parts capable of withstanding high temperatures? Understanding the 260°C Limit for Performance

- What are the applications of Granular PTFE? Unlock Superior Performance in Demanding Environments

- What are the main advantages of using Teflon bushings across different industries? Achieve Maintenance-Free Performance

- What automotive components are made using PTFE machining? Enhance Performance in Extreme Conditions

- In what types of industrial applications are PTFE-lined butterfly valves versatile? Handle Aggressive & Pure Media

- What are PTFE reducing flanges used for? Connect Pipes of Different Sizes with Superior Chemical Resistance

- Why is PTFE considered an effective sealing solution for various industries? Discover the Ultimate Material for Demanding Seals

- What are the main features of PTFE bellow mechanical seals? A Guide to Extreme Chemical Resistance and Reliability