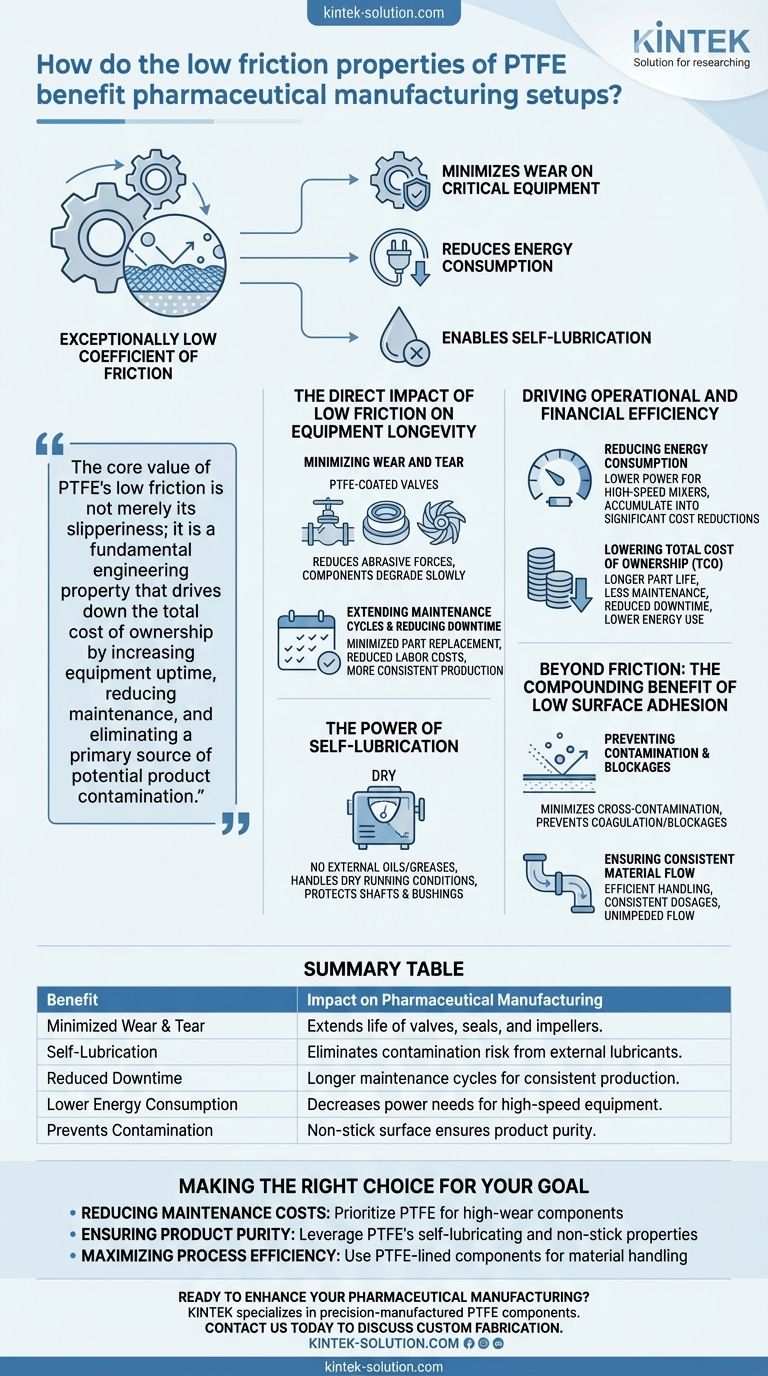

In pharmaceutical manufacturing, the low friction of Polytetrafluoroethylene (PTFE) translates directly into greater operational reliability and significant cost savings. Its exceptionally low coefficient of friction minimizes wear on critical equipment, reduces energy consumption, and enables self-lubrication, which enhances the longevity of machinery and protects product purity.

The core value of PTFE's low friction is not merely its slipperiness; it is a fundamental engineering property that drives down the total cost of ownership by increasing equipment uptime, reducing maintenance, and eliminating a primary source of potential product contamination.

The Direct Impact of Low Friction on Equipment Longevity

The most immediate benefit of PTFE's low friction is its effect on the mechanical integrity and lifespan of manufacturing equipment.

Minimizing Wear and Tear in Critical Components

In pharmaceutical machinery, components like valves, seals, and impellers are in constant motion. PTFE's low friction drastically reduces the abrasive forces between these moving parts.

This reduction in wear and tear means components degrade much more slowly, extending the operational life of the entire assembly.

Extending Maintenance Cycles and Reducing Downtime

Because PTFE components last longer, the need for part replacement is minimized. This directly translates to lower costs for spare parts and labor.

More importantly, it leads to reduced downtime for maintenance, allowing for more consistent and predictable production schedules.

The Power of Self-Lubrication

PTFE is inherently self-lubricating, a critical feature in an industry where product purity is paramount. It performs exceptionally well without external oils or greases that could contaminate sensitive pharmaceutical compounds.

This property also allows equipment to handle dry running conditions without seizure or failure, protecting assets like shaft seals and bushings from catastrophic damage.

Driving Operational and Financial Efficiency

Beyond equipment protection, the low-friction nature of PTFE creates tangible efficiencies that impact the bottom line.

Reducing Energy Consumption

In high-speed applications, such as mixers with PTFE impellers, overcoming friction requires energy. By minimizing this resistance, PTFE reduces the overall power consumption of the equipment.

While the savings per machine may seem small, they accumulate into significant cost reductions at the scale of a full production facility.

Lowering Total Cost of Ownership (TCO)

When evaluating materials, the initial purchase price is only part of the story. PTFE's benefits—longer part life, less maintenance, reduced downtime, and lower energy use—contribute to a significantly lower Total Cost of Ownership (TCO) over the equipment's lifespan.

Beyond Friction: The Compounding Benefit of Low Surface Adhesion

Closely related to its low friction is PTFE's low surface adhesion, or non-stick quality. This property is equally vital in pharmaceutical processes.

Preventing Contamination and Blockages

Pharmaceutical powders, pills, and viscous liquids can easily stick to machinery surfaces. PTFE’s low surface adhesion prevents this from happening.

This minimizes the risk of cross-contamination between batches and prevents coagulation or blockages that can halt production and compromise product quality.

Ensuring Consistent Material Flow

By ensuring that materials slide easily over surfaces, PTFE promotes a smooth and efficient handling process. This is essential for maintaining consistent dosages and ensuring the unimpeded flow of compounds through valves and tubing.

Making the Right Choice for Your Goal

When specifying materials for your equipment, aligning the properties of PTFE with your primary objectives is key.

- If your primary focus is reducing maintenance costs: Prioritize PTFE for high-wear components like valve diaphragms, seals, and bushings to maximize their operational life and minimize replacement frequency.

- If your primary focus is ensuring product purity: Leverage PTFE’s self-lubricating and non-stick properties to eliminate the risk of contamination from external lubricants or material buildup.

- If your primary focus is maximizing process efficiency: Use PTFE-lined components in material handling systems to ensure smooth, uninterrupted flow of powders and liquids, reducing blockages and production delays.

Ultimately, selecting PTFE is a strategic decision that invests in predictable, clean, and cost-effective pharmaceutical production.

Summary Table:

| Benefit | Impact on Pharmaceutical Manufacturing |

|---|---|

| Minimized Wear & Tear | Extends life of valves, seals, and impellers. |

| Self-Lubrication | Eliminates contamination risk from external lubricants. |

| Reduced Downtime | Longer maintenance cycles for consistent production. |

| Lower Energy Consumption | Decreases power needs for high-speed equipment like mixers. |

| Prevents Contamination | Non-stick surface ensures product purity and batch integrity. |

Ready to enhance your pharmaceutical manufacturing with high-performance PTFE components?

KINTEK specializes in precision-manufactured PTFE seals, liners, valves, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our components are engineered to reduce your total cost of ownership by maximizing equipment uptime and protecting product purity.

Contact us today to discuss custom fabrication from prototypes to high-volume orders and discover the KINTEK difference in reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the chemical composition of PTFE and why is it significant? Unlocking Its Unique Properties

- What are some well-known applications of PTFE? Unlock Its Versatility in Your Industry

- What industrial applications utilize expanded PTFE? Sealing, Filtration & Insulation Solutions

- What is the hardness of PTFE on the Shore scale? A Guide to Its Softness and Performance

- What are the notable physical and chemical properties of PTFE? Master Its Unique Strengths and Limitations

- Why is PTFE approved for medical implants? Leveraging Biocompatibility for Medical Devices

- How is Expanded PTFE (EPTFE) material constructed? A Deep Dive into the Microporous Transformation

- How does PTFE compare to Polyether Ether Ketone (PEEK)? Strength vs. Chemical Resistance