At their core, Teflon and UHMW are both high-performance, low-friction polymers, but they are engineered for fundamentally different operational demands. Teflon (PTFE) is the material of choice for applications requiring extreme temperature resistance, chemical inertness, and non-stick surfaces. In contrast, UHMW (Ultra-High-Molecular-Weight Polyethylene) is selected for its exceptional toughness, impact strength, and unparalleled resistance to abrasion and wear.

The decision between Teflon and UHMW is a classic engineering trade-off. You must choose between Teflon's superior thermal and chemical stability and UHMW's superior mechanical durability and wear resistance.

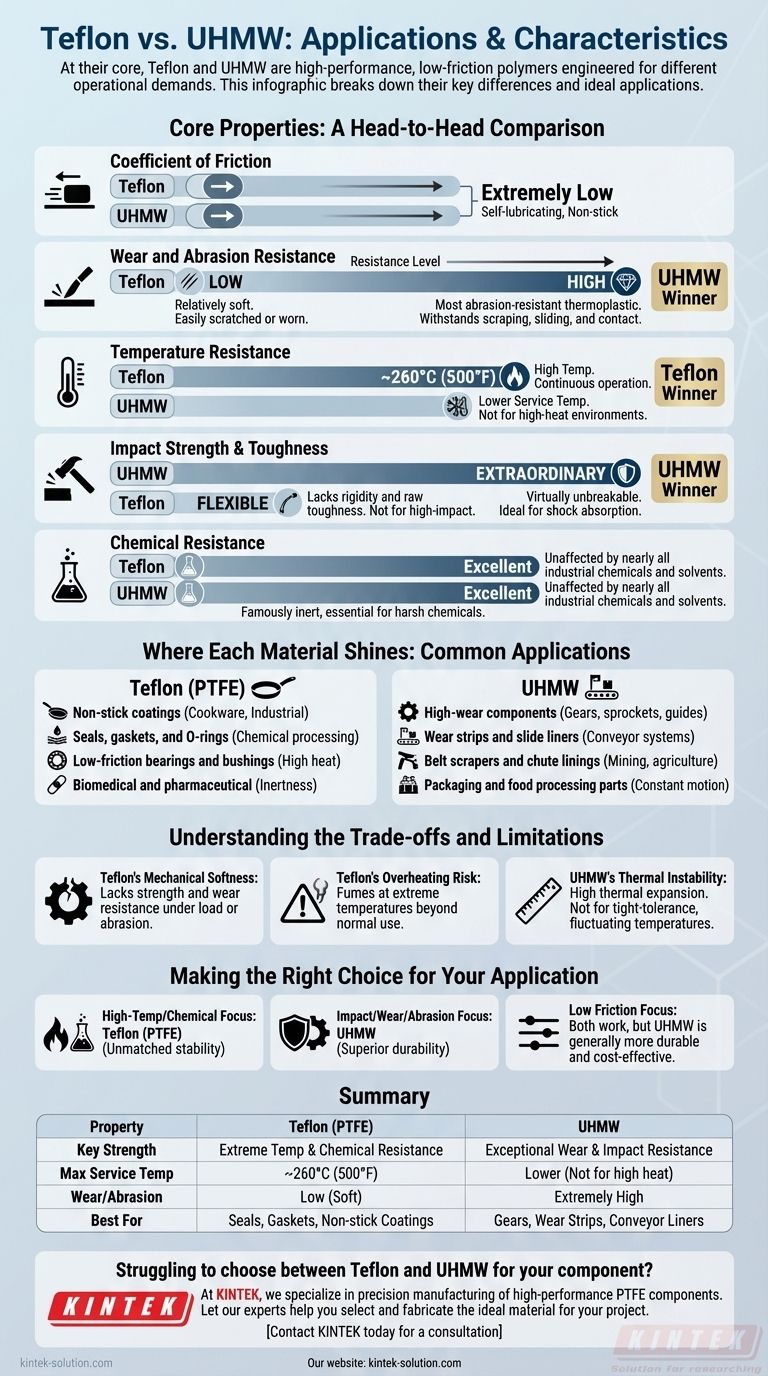

Core Properties: A Head-to-Head Comparison

Understanding the key differences in their material properties is the first step in selecting the right polymer for your application.

H3: Coefficient of Friction

Both materials are celebrated for their extremely low coefficient of friction, making them excellent self-lubricating plastics. They provide smooth, non-stick surfaces that reduce energy consumption in moving parts.

H3: Wear and Abrasion Resistance

This is the single greatest distinction. UHMW is one of the most abrasion-resistant thermoplastics available, far outperforming Teflon. It is designed to withstand scraping, sliding, and contact in high-wear industrial environments.

Teflon, by comparison, is a relatively soft material. While slippery, it can be easily scratched or worn away under abrasive conditions.

H3: Temperature Resistance

Teflon is the clear winner for high-temperature applications. It can operate continuously at temperatures up to 260°C (500°F) without significant degradation.

UHMW has a much lower service temperature and can exhibit thermal instability. It is not suitable for high-heat environments or for high-precision components that experience temperature fluctuations.

H3: Impact Strength and Toughness

UHMW possesses extraordinary impact strength and is virtually unbreakable. This toughness makes it ideal for components that must absorb shock and resist fracture, such as gears, bumpers, and wear pads.

Teflon is flexible but lacks the rigidity and raw toughness of UHMW. It is not considered a structural material for high-impact roles.

H3: Chemical Resistance

Both polymers offer excellent chemical resistance. However, Teflon is famously inert and is unaffected by nearly all industrial chemicals and solvents, making it essential for seals, gaskets, and linings in harsh chemical processing.

Where Each Material Shines: Common Applications

The property differences dictate where these materials are most commonly and effectively deployed.

H3: Typical Use Cases for Teflon (PTFE)

Teflon's unique combination of non-stick, high-temperature, and chemical-resistant properties makes it ideal for:

- Non-stick coatings on cookware and industrial equipment.

- Seals, gaskets, and O-rings in chemical processing plants.

- Low-friction bearings and bushings where heat is a factor.

- Biomedical and pharmaceutical applications due to its inertness.

H3: Typical Use Cases for UHMW

UHMW’s extreme durability makes it a staple material for heavy-duty industrial machinery and material handling systems:

- High-wear components like gears, sprockets, and chain guides.

- Wear strips and slide liners for conveyor systems.

- Belt scrapers and chute linings in mining and agriculture.

- Parts for packaging and food processing machines that see constant motion and impact.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging their respective weaknesses is critical for avoiding application failure.

H3: Teflon's Mechanical Softness

The primary limitation of Teflon is its lack of strength and wear resistance. It should not be used for mechanical parts that are under significant load or subject to abrasive forces.

H3: Teflon's Overheating Risk

While stable at high operating temperatures, Teflon can release harmful fumes if heated to extreme temperatures well beyond normal use, a concern primarily associated with consumer cookware.

H3: UHMW's Thermal Instability

The most significant drawback of UHMW is its high rate of thermal expansion. It is not suitable for tight-tolerance components that must maintain precise dimensions across a range of temperatures.

Making the Right Choice for Your Application

Your primary operational challenge will determine the correct material.

- If your primary focus is high-temperature performance or chemical inertness: Teflon (PTFE) is the only logical choice for its unmatched stability in these conditions.

- If your primary focus is resisting impact, abrasion, and wear: UHMW is the superior material, offering unparalleled toughness for demanding mechanical applications.

- If your primary focus is simply low friction without other extremes: Both can work, but UHMW is generally the more durable and cost-effective choice for industrial sliding parts.

By matching your application's most critical need to the material that excels in that area, you ensure long-term reliability and performance.

Summary Table:

| Property | Teflon (PTFE) | UHMW |

|---|---|---|

| Key Strength | Extreme Temperature & Chemical Resistance | Exceptional Wear & Impact Resistance |

| Max Service Temp | ~260°C (500°F) | Lower (Not for high heat) |

| Wear/Abrasion | Low (Soft) | Extremely High |

| Best For | Seals, Gaskets, Non-stick Coatings | Gears, Wear Strips, Conveyor Liners |

Struggling to choose between Teflon and UHMW for your component?

At KINTEK, we specialize in precision manufacturing of high-performance PTFE components like seals, liners, and custom labware. Whether your application demands Teflon's superior chemical inertness for the semiconductor or medical industries, or requires a custom-fabricated solution, we deliver the precision and reliability you need—from prototypes to high-volume production.

Let our experts help you select and fabricate the ideal material for your project's unique demands.

Contact KINTEK today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does the electronegativity of fluorine affect PTFE's structure? The Key to Its Unmatched Chemical Resistance

- Who discovered PTFE and when? The Accidental Invention of Teflon

- What are the temperature limits for PTFE? Master Its Extreme Thermal Range from -200°C to +260°C

- What aerospace applications use Teflon? Unlock Reliability in Extreme Environments

- What are some applications of PTFE due to its properties? Discover Its Versatility in Demanding Industries

- What factors influence the price fluctuations of PTFE? A Guide to Navigating Raw Material Costs

- How does PTFE perform under long-term exposure to weather and UV light? Unmatched Durability for Decades

- What impact has PTFE industrial coating had on daily life? Unlocking Modern Convenience & Performance