The short answer is that spring energized PTFE seals provide consistent force by separating the sealing function from the energizing function. Unlike a traditional rubber seal which must be both the barrier and the spring, this design uses a durable metal spring to provide a constant, predictable mechanical load on a separate, high-performance PTFE seal jacket.

The core principle is simple but effective: A metal spring provides unwavering mechanical force, while the Polytetrafluoroethylene (PTFE) jacket provides the low-friction, chemically-resistant sealing interface. This division of labor overcomes the limitations of traditional elastomeric seals.

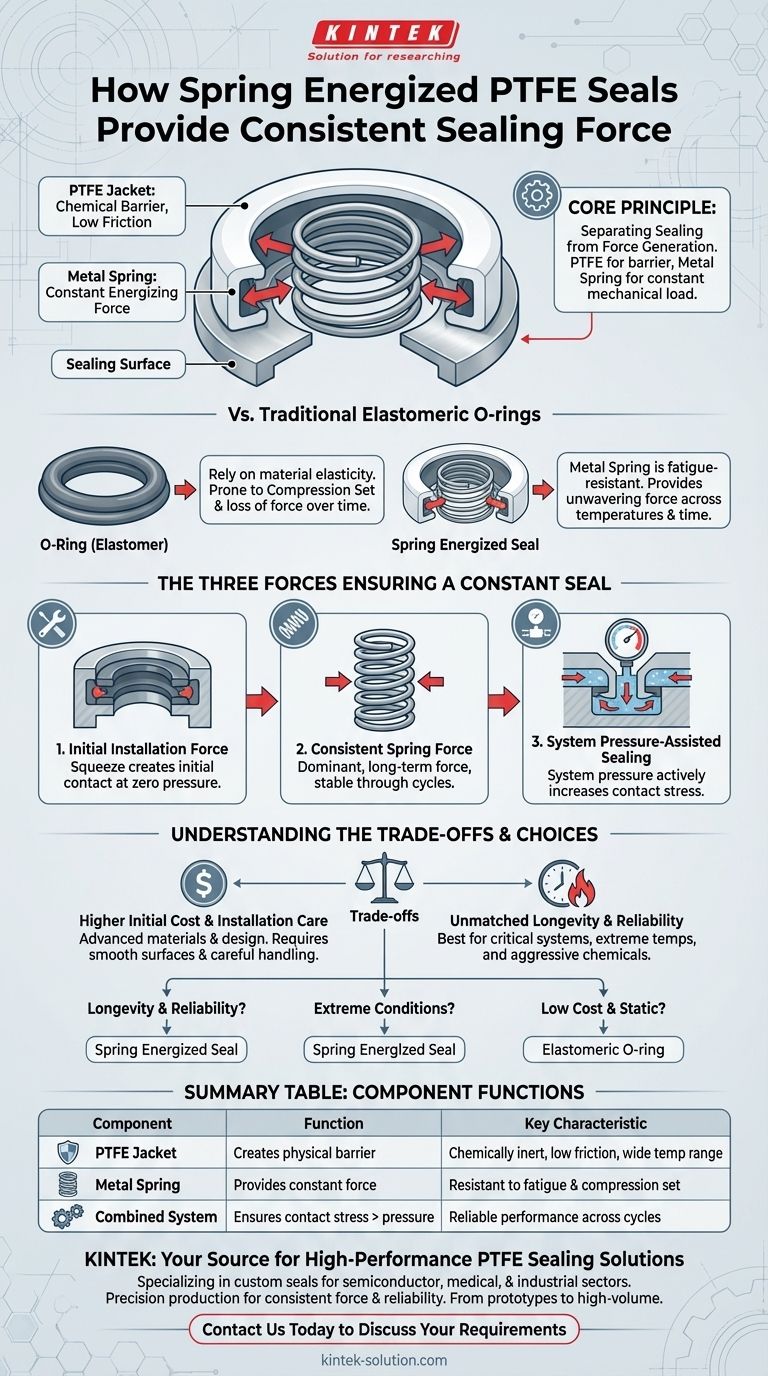

The Core Principle: Separating Sealing from Force Generation

To truly understand their reliability, you must see spring energized seals as a system of two components, each perfectly suited for its specific job. This is a fundamental departure from the design of a standard O-ring.

The Role of the PTFE Jacket

The outer jacket is made from PTFE or a similar high-performance polymer. Its primary job is to create the physical barrier against the fluid being sealed. This material is chosen for its exceptional chemical resistance, wide temperature tolerance, and extremely low coefficient of friction.

The Function of the Metal Spring

Nestled inside the PTFE jacket is a metal spring. This is the engine of the seal. Its sole purpose is to exert a continuous, live force, pushing the lips of the PTFE jacket outward and/or inward against the sealing surfaces. This spring is what provides the seal's "energy" and resilience over time.

Why This Differs from Elastomeric Seals

A traditional rubber or polyurethane O-ring is made from a resilient material that is compressed during installation. Its sealing force comes from its own material elasticity trying to return to its original shape. Over time, under heat and pressure, this material can lose its resilience—a phenomenon known as compression set—leading to a loss of sealing force and eventual failure.

Spring energized seals avoid this problem because the metal spring is far more resistant to fatigue and temperature changes than any elastomer.

The Three Forces Ensuring a Constant Seal

The total sealing force is not just from the spring alone. It is a combination of three distinct forces that work together to ensure the contact stress on the sealing surface always exceeds the pressure of the fluid being contained.

Initial Force from Installation

When the seal is installed in its gland, the PTFE jacket is slightly compressed. This initial "squeeze" or pre-load creates the first layer of sealing force, ensuring a tight fit even at zero pressure.

The Consistent Force from the Spring Energizer

This is the dominant force that guarantees long-term performance. The metal spring is constantly trying to expand, creating a consistent load on the seal lips. This force remains stable through pressure cycles, temperature fluctuations, and long periods of service.

System Pressure-Assisted Sealing

The U-cup shape of the PTFE jacket is a critical design feature. As system pressure increases, the fluid enters the cavity of the "U" and acts upon the inner surfaces of the seal lips. This pressure actively pushes the lips harder against the sealing surfaces, effectively using the system's own energy to increase the sealing force.

Understanding the Trade-offs

While highly effective, spring energized seals are not a universal solution. Their design brings a specific set of considerations.

Higher Initial Cost

The multi-component design and advanced materials make these seals more expensive upfront than a simple elastomeric O-ring. Their value is realized in applications where reliability and long life justify the initial investment.

Sensitivity to Surface Finish

PTFE is a harder material than most elastomers. It is less forgiving of imperfections in the sealing surfaces. A smooth, well-prepared hardware surface finish is critical to prevent leak paths and ensure optimal seal performance.

Installation Care

The relative stiffness of the PTFE jacket means that more care must be taken during installation to avoid scratching or gouging the seal lips, which could compromise their integrity.

Making the Right Choice for Your Goal

Selecting the correct seal depends entirely on the demands of the application.

- If your primary focus is longevity and reliability in a critical system: Choose a spring energized seal for its resistance to compression set and its consistent sealing force over tens of thousands of hours.

- If your primary focus is performance in extreme temperatures or aggressive chemicals: The combination of a metal spring and a chemically inert PTFE jacket is one of the only solutions that can operate reliably in these conditions.

- If your primary focus is a low-cost seal for a standard, static application: A traditional elastomeric O-ring is often the more practical and cost-effective choice.

By mechanically generating force with a spring, this seal technology provides a robust and predictable solution for the most demanding engineering challenges.

Summary Table:

| Component | Function | Key Characteristic |

|---|---|---|

| PTFE Jacket | Creates the physical barrier | Chemically inert, low friction, wide temperature range |

| Metal Spring | Provides constant energizing force | Resistant to fatigue and compression set |

| Combined System | Ensures contact stress exceeds system pressure | Reliable performance across pressure cycles and temperatures |

Need a reliable sealing solution for your critical application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom spring energized seals, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures consistent force and long-term reliability, even in extreme temperatures and aggressive chemical environments.

We offer custom fabrication from prototypes to high-volume orders. Let us provide the robust sealing solution your project demands.

Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the primary applications of PTFE ring gaskets? Solve Your Toughest Sealing Challenges

- What are the mechanical applications of PTFE rods? Solve Friction and Corrosion Problems

- How do PTFE expansion bellows contribute to cost savings in power plants? Slash Maintenance and Downtime Costs

- What is the primary function of PTFE pneumatic valves? Control Corrosive Media with Unmatched Reliability

- Why is it important to consider PTFE lining standards when selecting a supplier? Avoid Costly Failures

- What overall benefits do PTFE expansion joints provide to industrial systems? Enhance System Reliability and Longevity

- How does PTFE compare to other elastomers in temperature resilience? Unmatched Performance from -200°C to 260°C

- What are the unique properties of PTFE that make it suitable for CNC machining? Master Machining for Superior Components