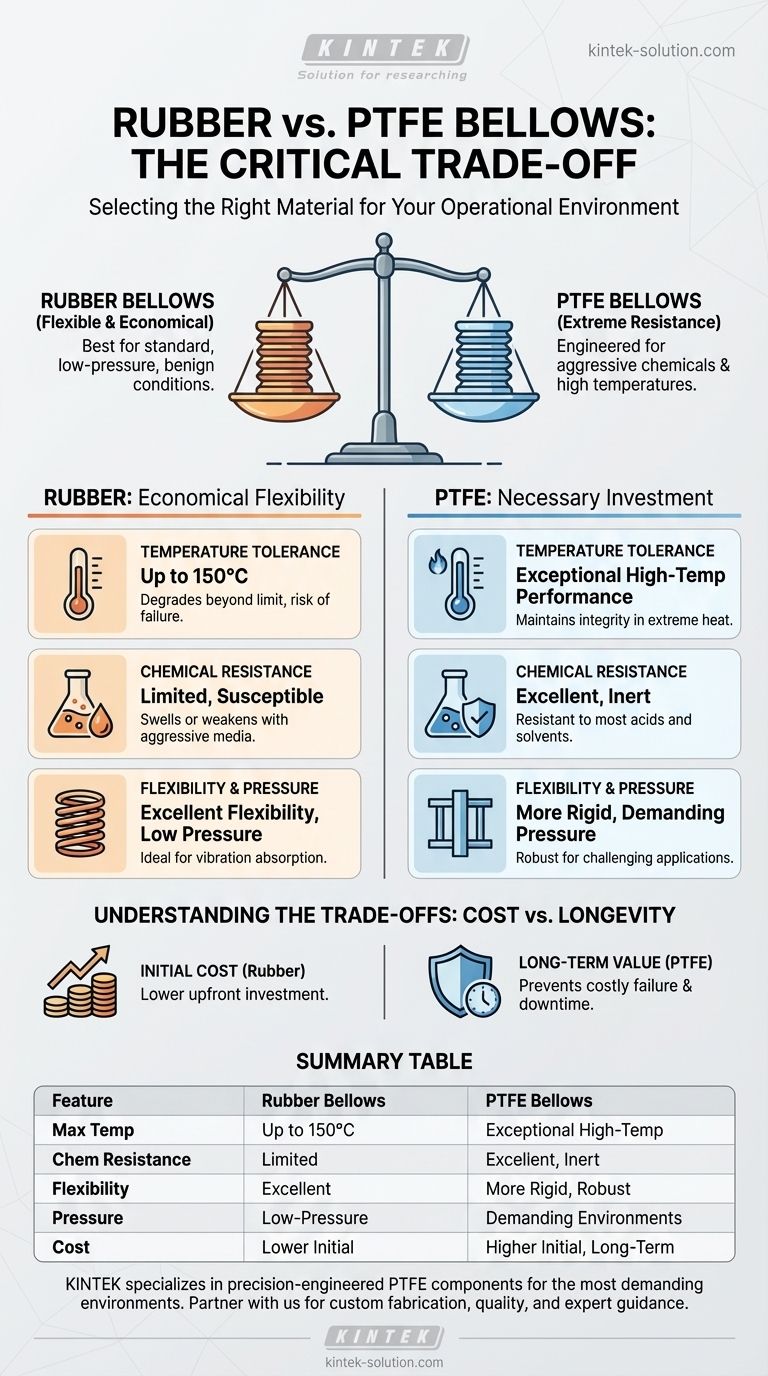

When selecting an expansion joint, the choice between rubber and PTFE bellows hinges on their distinct operational capabilities. Rubber bellows provide excellent flexibility and are highly cost-effective for standard, low-pressure applications. In contrast, PTFE bellows are engineered for extreme environments, offering unparalleled resistance to aggressive chemicals and high temperatures where rubber would quickly fail.

The decision is not about which material is universally "better," but which is correct for a specific operational environment. The choice represents a fundamental trade-off: rubber offers economical flexibility for benign conditions, while PTFE is the necessary investment for systems demanding high chemical and thermal resistance.

Core Performance Characteristics: A Direct Comparison

To make an informed decision, it's crucial to evaluate the materials based on the specific demands of your system. The primary differentiators are temperature tolerance, chemical resistance, and mechanical flexibility.

Temperature Tolerance

PTFE bellows demonstrate exceptional performance in extreme heat. They maintain their structural integrity in high-temperature environments, such as those found in power plants or chemical processing facilities.

Rubber bellows have a much lower thermal limit, typically handling temperatures only up to 150°C. Beyond this threshold, rubber will degrade, lose its properties, and ultimately lead to joint failure.

Chemical Resistance

PTFE is renowned for being one of the most chemically inert materials used in industry. It can handle a vast range of aggressive media, including strong acids and solvents, without corroding or degrading.

This makes PTFE the mandatory choice for applications in chemical manufacturing, pharmaceuticals, and food processing. Rubber, on the other hand, is susceptible to attack from many chemicals, which can cause it to swell, weaken, or dissolve over time.

Flexibility and Pressure Handling

Rubber provides excellent flexibility, making it highly effective at absorbing vibrations and accommodating movement in piping systems. It is an ideal solution for many low-pressure applications.

While PTFE is a robust material, it is inherently more rigid than rubber. This means that for applications where extreme, multi-axial flexibility is the single most important factor, a specialized rubber or composite joint might be considered.

Understanding the Trade-offs: Cost vs. Longevity

Choosing the wrong material can lead to consequences far more expensive than the initial cost of the component itself. It's a balance between upfront investment and long-term system reliability.

The Initial Cost Factor

Rubber bellows are significantly more affordable than their PTFE counterparts. This makes them the clear economic choice for general-purpose applications with moderate temperatures and non-corrosive media, such as water lines or HVAC systems.

The Hidden Costs of Misapplication

Using a rubber bellow in an environment with incompatible chemicals or high temperatures is a critical error. This misapplication will lead to premature failure, resulting in dangerous leaks, process contamination, and costly operational downtime.

The higher initial price of a PTFE bellow should be viewed as an investment in safety and system integrity. In a demanding application, it prevents the far greater costs associated with failure and replacement.

Considering Alternatives

While rubber and PTFE cover many use cases, other materials exist for specific needs. Metal bellows excel in very high-pressure and high-temperature systems where chemical corrosion is not a concern. Composite bellows can offer a customized balance of flexibility and strength for unique applications.

Making the Right Choice for Your Application

To select the correct material, evaluate your system’s primary operational demands against the strengths of each option.

- If your primary focus is cost-effectiveness for low-pressure, non-corrosive media (like water or air): Rubber bellows are the most practical and economical choice.

- If your system involves aggressive chemicals, high temperatures, or sanitary requirements: PTFE bellows are the only reliable option to ensure safety and system longevity.

- If your application demands extreme pressure and temperature resistance without harsh chemical exposure: A metal bellow may be a more suitable alternative.

Choosing the right bellows material is a critical engineering decision that directly impacts the safety, reliability, and lifespan of your entire system.

Summary Table:

| Feature | Rubber Bellows | PTFE Bellows |

|---|---|---|

| Max Temperature | Up to 150°C | Exceptional high-temperature performance |

| Chemical Resistance | Limited, degrades with aggressive media | Excellent, inert to most acids and solvents |

| Flexibility | Excellent for vibration absorption | More rigid, but robust |

| Pressure Handling | Ideal for low-pressure applications | Suitable for demanding environments |

| Cost | More affordable initial investment | Higher initial cost, long-term value |

| Best For | Water lines, HVAC, benign conditions | Chemical processing, pharmaceuticals, high heat |

Ensure the Integrity of Your Critical Systems

Selecting the wrong bellows material can lead to premature failure, dangerous leaks, and costly downtime. The choice between rubber and PTFE is critical for your system's safety and longevity.

KINTEK specializes in precision-engineered PTFE components, including custom bellows for the most demanding environments. We serve semiconductor, medical, laboratory, and industrial sectors where material integrity is non-negotiable.

Partner with us for:

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your exact specifications.

- Uncompromising Quality: Our PTFE components offer the superior chemical and thermal resistance your application demands.

- Expert Guidance: Leverage our expertise to select the perfect material for reliability and performance.

Don't compromise on safety or performance. Contact our experts today to discuss your specific requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the maximum working temperature for Teflon balls? Ensuring Safe and Reliable Performance

- What are some unusual industries where PTFE bellows are utilized? Mastering Extreme Purity, Heat, and Precision

- What are the specifications of a high-pressure, low-speed PTFE seal profile? Handle 3,000 psi with Confidence

- What industries commonly use PTFE butterfly valves and why? For Superior Chemical Resistance & Purity

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the advantages of PTFE-lined butterfly valves over lined ball valves in pharmaceutical applications? Achieve Superior Sterility and Cleanability

- What are some key characteristics of Teflon and PTFE that make them suitable for building construction? Enable Durable, Low-Maintenance Structures

- What are the alternative names for PTFE bush? A Guide to Sourcing the Right Component