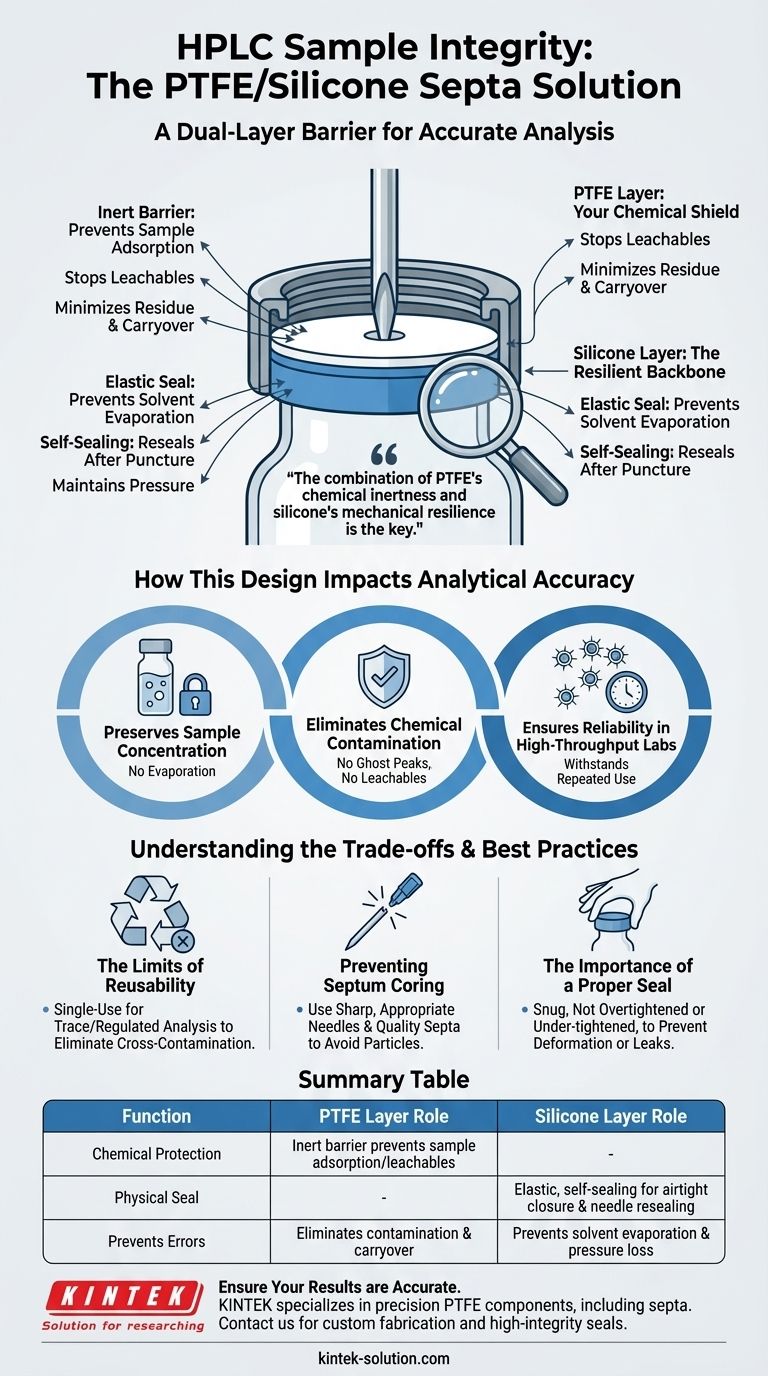

In high-performance liquid chromatography (HPLC), the integrity of your results begins the moment you seal the vial. A PTFE/silicone septum maintains sample integrity by creating a dual-layer barrier. The chemically inert Polytetrafluoroethylene (PTFE) layer faces the sample to prevent contamination and adsorption, while the elastic silicone layer provides a physically resilient and resealable seal against the environment and repeated needle punctures.

The combination of PTFE's chemical inertness and silicone's mechanical resilience is the key. This design ensures that the sample you analyze is identical to the sample you prepared, free from contamination, concentration changes, and degradation.

The Anatomy of a High-Integrity Seal

To understand why these septa are the industry standard, we must look at how the two materials function as a synergistic system. Each layer plays a distinct but critical role.

The PTFE Layer: Your Chemical Shield

The layer that makes direct contact with your sample is a thin film of PTFE. This material is chosen for its extreme chemical inertness.

Its primary function is to prevent any interaction between the sample and the silicone. This shield stops analyte molecules from adsorbing onto the septum surface and prevents contaminants from leaching out of the silicone into your sample.

The smooth, non-stick surface of PTFE also minimizes sample residue. This is crucial for preventing carryover, where traces of a previous sample contaminate the next one, ensuring accuracy in trace-level analysis.

The Silicone Layer: The Resilient Backbone

Beneath the PTFE shield lies a thicker layer of high-purity silicone. This material provides the mechanical functionality of the seal.

Silicone is highly elastic, allowing it to form a tight, conforming seal against the glass rim of the vial. This physical barrier prevents solvent evaporation, which would otherwise alter the concentration of your sample and invalidate quantitative results.

Most importantly, silicone is self-sealing. When the autosampler needle pierces the septum, the silicone's elasticity allows it to close tightly around the needle and reseal effectively after the needle is withdrawn. This property is essential for high-throughput labs where vials may be punctured multiple times.

How This Design Impacts Analytical Accuracy

The dual-layer construction directly prevents the most common sources of analytical error that originate from the sample vial.

Preserving Sample Concentration

Evaporation is a silent destroyer of accuracy. By creating an airtight seal, a PTFE/silicone septum ensures that volatile solvents do not escape, maintaining the precise concentration of your standards and unknowns from preparation to injection.

Eliminating Chemical Contamination

A faulty septum can introduce ghost peaks or alter your sample's chemistry. The inert PTFE layer acts as an impenetrable barrier, protecting the sample from leachable compounds within the silicone and from any external contaminants.

Ensuring Reliability in High-Throughput Labs

Modern autosamplers analyze hundreds of samples sequentially. The septum's ability to withstand repeated punctures without failure is paramount. A properly designed septum prevents vial pressure loss and sample degradation over long analytical runs, ensuring the last sample is as secure as the first.

Understanding the Trade-offs and Best Practices

While highly effective, choosing and using these septa requires an understanding of their limitations to guarantee performance.

The Limits of Reusability

Although the self-sealing nature of silicone allows for multiple punctures, reusing septa is a significant trade-off between cost and data integrity. For trace analysis, regulated methods (e.g., pharmaceuticals), or validation, always use a new septum for each sample to eliminate any risk of cross-contamination from microscopic tears or residue.

Preventing Septum Coring

"Coring" occurs when the needle punches out a small piece of the septum, which then falls into the sample. This can block the needle or column and introduce contamination. It is often caused by using a blunt needle or a poorly manufactured septum. Always use high-quality septa and sharp, appropriate-gauge needles to avoid this issue.

The Importance of a Proper Seal

Overtightening or under-tightening the vial cap can compromise the seal. Overtightening can deform the septum, causing it to bulge and preventing proper resealing. Under-tightening creates a poor seal, allowing evaporation. Always tighten the cap until it is snug, but not forced.

Making the Right Choice for Your Analysis

Your analytical goal should dictate your choice and handling of vial septa.

- If your primary focus is trace-level analysis or regulatory compliance: Prioritize single-use, high-purity PTFE/silicone septa to ensure maximum data defensibility and eliminate carryover risk.

- If your primary focus is high-throughput screening: Select septa specifically rated for a high number of punctures to maintain seal integrity throughout long, unattended sequences.

- If your primary focus is routine analysis in a non-critical setting: You may consider septum reuse, but only with rigorous vial cleaning and a clear understanding of the potential impact on result precision.

Ultimately, treating the vial septum as a critical component of the analytical method empowers you to safeguard the integrity of your results from the very start.

Summary Table:

| Function | PTFE Layer Role | Silicone Layer Role |

|---|---|---|

| Chemical Protection | Inert barrier prevents sample adsorption/leachables | - |

| Physical Seal | - | Elastic, self-sealing for airtight closure and needle resealing |

| Prevents Errors | Eliminates contamination & carryover | Prevents solvent evaporation & pressure loss |

Ensure your HPLC results are accurate from the start. The integrity of your analysis depends on high-quality vial seals. KINTEK specializes in manufacturing precision PTFE components, including septa, for the semiconductor, medical, and laboratory industries.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact seal your application requires for reliable, contamination-free performance.

Contact KINTEK today to discuss your specific needs and safeguard your sample integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware

- How do PTFE silicone septas enhance efficiency in pharmaceutical analytical processes? Boost Lab Throughput & Data Integrity

- What is PTFE and how is it used in vial caps? Ensure Sample Purity with Inert Liner Technology

- What temperature range can PTFE shovels withstand? A Guide to Extreme Thermal Stability

- What are the advantages of using PTFE laboratory bottles? Unmatched Chemical Resistance for Critical Samples

- What material is used to mold PTFE labware? The Critical Role of Pure PTFE Resin

- In which industries are PTFE lined caps commonly used? Ensure Product Purity & Chemical Resistance

- What makes PTFE vials effective in preventing sample contamination or evaporation? Superior Chemical Inertness & Airtight Seals