For electrical insulation, PTFE is the definitive choice over rubber. PTFE (Polytetrafluoroethylene) is an exceptional electrical insulator by its very nature, designed to prevent the flow of current safely and reliably. In contrast, many common rubber compounds can be conductive and are entirely unsuitable for applications where electrical insulation is a primary requirement.

The core distinction is simple: PTFE is a premier, high-performance insulator used to protect sensitive electronics and high-voltage systems. Rubber is primarily a flexible sealant or damper, whose electrical properties are unreliable and often conductive, making it a significant risk in insulating applications.

Why PTFE Excels as an Electrical Insulator

The properties that make PTFE a superior insulator are rooted in its fundamental molecular structure and material characteristics.

The Chemical Basis for Insulation

PTFE's synthetic polymer structure is incredibly stable and does not have free electrons that can move to conduct an electrical current. This inherent property, known as high dielectric strength, allows it to resist electrical flow effectively.

This molecular stability ensures it acts as a reliable barrier, preventing electrical shorts and current leakage between components.

High-Voltage Capability

PTFE is engineered to withstand very high voltages without breaking down. This makes it an essential material for insulators in demanding high-voltage equipment and sensitive electronic systems.

Its performance under electrical stress ensures the safety and longevity of the components it protects.

Water and Moisture Resistance

PTFE is hydrophobic, meaning it actively repels water. In electrical applications, moisture is a primary cause of short circuits and system failure.

By preventing water absorption, PTFE washers maintain their insulating properties even in damp or humid environments, protecting the integrity of electrical assemblies.

The Problem with Rubber for Insulation

While "rubber" is a common term, it describes a wide range of elastomer materials with vastly different and often unsuitable properties for insulation.

Variable and Often Conductive Nature

Unlike PTFE, rubber is not a single material. Many formulations, especially those containing carbon black as a reinforcing agent, are semi-conductive.

Using a standard rubber washer in an electrical application can inadvertently create a pathway for current, leading to malfunction or catastrophic failure. Only specialized, and clearly specified, dielectric rubber compounds are suitable for any electrical work.

Focus on Mechanical Properties

Rubber's primary engineering benefits are its flexibility, compressibility, and ability to dampen vibration. Its formulation is optimized for these mechanical tasks, not for electrical performance.

This focus means its electrical properties are, at best, an afterthought and, at worst, a direct hazard if misused as an insulator.

Understanding the Trade-offs

Choosing the right washer depends entirely on the primary function it must serve. Electrical insulation is only one of many potential requirements.

When to Choose PTFE

PTFE is the non-negotiable choice for applications involving electricity. This includes insulating fasteners in electronic circuit boards, separating components in high-voltage enclosures, or protecting sensitive circuits from interference.

Its additional benefits of extreme chemical resistance and a very low coefficient of friction make it ideal for harsh industrial environments or moving parts.

When to Choose Rubber

Rubber washers are superior for general-purpose sealing against water and dust, absorbing vibrations, and providing a flexible cushion between parts.

If your application has no electrical insulation requirement, a rubber washer is often a more cost-effective and flexible solution for creating a tight seal or reducing noise.

Making the Right Choice for Your Application

To select the correct material, you must be clear about your primary engineering goal.

- If your primary focus is critical electrical insulation: Choose PTFE. Its high dielectric strength and moisture resistance are essential for safety and performance in any electrical or electronic system.

- If your primary focus is sealing, flexibility, or vibration damping: Choose rubber, but only in applications where there is absolutely no risk of creating an unintended electrical path.

- If your primary focus is waterproofing an electrical component: Choose PTFE. It provides both excellent electrical insulation and superior water repellency, ensuring long-term reliability.

Ultimately, selecting the right material is the foundation of a safe and effective design.

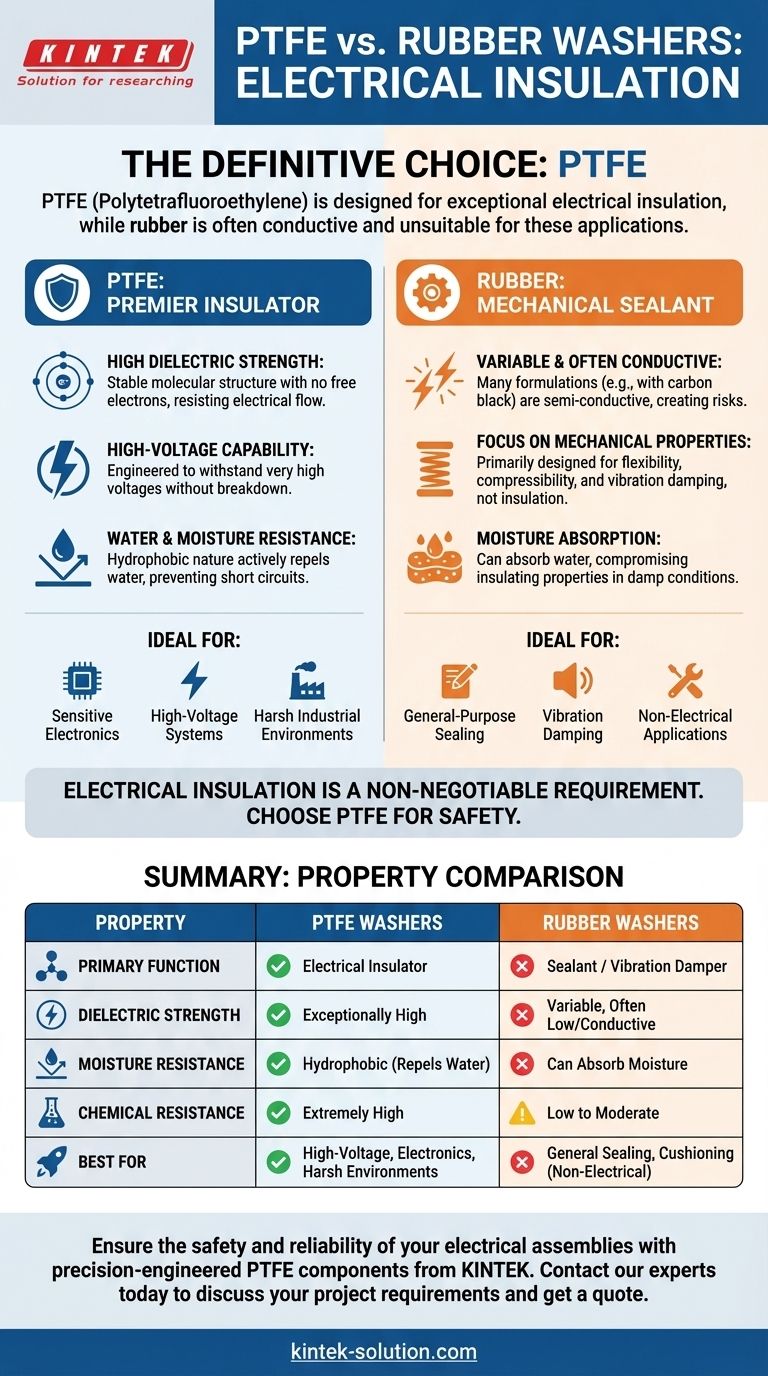

Summary Table:

| Property | PTFE Washers | Rubber Washers |

|---|---|---|

| Primary Function | Electrical Insulator | Sealant / Vibration Damper |

| Dielectric Strength | Exceptionally High | Variable, Often Low/Conductive |

| Moisture Resistance | Hydrophobic (Repels Water) | Can Absorb Moisture |

| Chemical Resistance | Extremely High | Low to Moderate |

| Best For | High-Voltage, Electronics, Harsh Environments | General Sealing, Cushioning (Non-Electrical) |

Ensure the safety and reliability of your electrical assemblies with precision-engineered PTFE components from KINTEK.

For semiconductor, medical, laboratory, and industrial applications, the wrong insulating material can lead to system failure or safety hazards. KINTEK specializes in manufacturing high-performance PTFE seals, liners, and labware that provide the critical dielectric strength and chemical resistance your designs demand.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and superior performance for your specific needs.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Are Teflon sheets reusable? Maximize Their Lifespan for Cost-Effective Projects

- Which industries commonly use PTFE cryogenic seals? Essential for Aerospace, Oil & Gas, and Pharma

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What nominal pressure ratings are available for PTFE gaskets? Understand the Limits of Pure PTFE

- How do PTFE lined butterfly valves provide protection against chemicals and rust? Achieve Superior Corrosion Resistance

- What is the thermal shock method for cleaning Teflon residue? Safely Remove Stubborn PTFE Buildup

- What challenges are associated with machining Teflon and how are they addressed? Master Precision PTFE Manufacturing

- What factors should be considered when choosing between PTFE and non-PTFE laminates? Optimize Performance vs. Cost