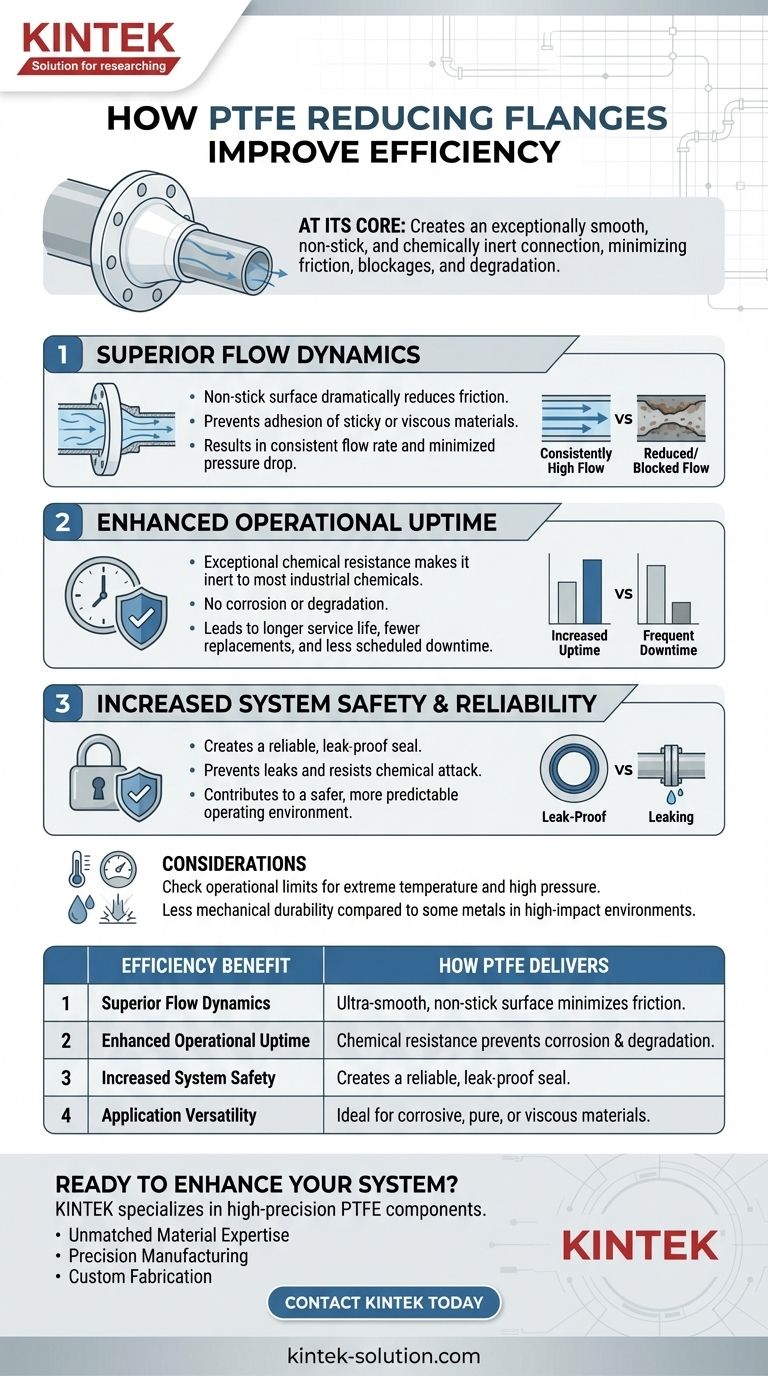

At its core, a PTFE reducing flange improves efficiency by creating an exceptionally smooth, non-stick, and chemically inert connection point between two different-sized pipes. This unique combination of properties minimizes friction, prevents blockages, and resists degradation, leading to more consistent flow, less downtime, and greater overall system reliability.

Connecting pipes of different diameters is a common necessity in industrial systems, but the choice of component has significant consequences. A PTFE reducing flange enhances efficiency not just by optimizing fluid dynamics, but by fundamentally increasing the system's operational uptime and safety through its material properties.

The Role of a PTFE Reducing Flange

To understand its impact on efficiency, we first must clarify the component's dual function: its shape and its material.

The Function of a Reducing Flange

A reducing flange is a specialized connector designed to join a larger pipe to a smaller one. This change in diameter is a critical transition point in any fluid-handling system.

How this transition is managed directly affects pressure, flow rate, and the potential for turbulence within the system.

The Advantage of PTFE Material

The flange is made from PTFE (Polytetrafluoroethylene), a high-performance fluoropolymer. The material itself is what delivers the primary efficiency benefits.

Key properties include extreme chemical resistance, a wide temperature tolerance, and an incredibly low coefficient of friction, making its surface non-stick.

How Efficiency is Directly Improved

Efficiency gains from PTFE reducing flanges are not from a single feature but from the combined effect of its material characteristics on system performance and maintenance.

Superior Flow Dynamics

The primary efficiency gain comes from the non-stick surface of the PTFE. This ultra-smooth surface dramatically reduces friction as fluids or materials pass through it.

This prevents materials, especially sticky or viscous ones, from adhering to the flange walls. The result is a consistent flow rate, minimized pressure drop, and a significantly lower risk of clogs or blockages that could halt production.

Enhanced Operational Uptime

Industrial systems lose efficiency every time they are shut down for maintenance or repair. PTFE's exceptional chemical resistance makes it inert to nearly all industrial chemicals and solvents.

This means the flange will not corrode or degrade, even when handling aggressive substances. This durability translates directly into longer service life, fewer replacements, and less scheduled downtime, boosting overall operational efficiency.

Increased System Safety and Reliability

Leaks are a major source of inefficiency, leading to lost product, safety hazards, and cleanup-related downtime. PTFE flanges create a reliable, leak-proof seal.

By preventing leaks and resisting chemical attack, these flanges contribute to a safer and more predictable operating environment. A reliable system is an efficient system.

Understanding the Trade-offs

While highly effective, PTFE is not the universal solution for every application. Understanding its limitations is key to making an informed decision.

Temperature and Pressure Boundaries

PTFE has a well-defined operational temperature range. While broad, it cannot handle the extreme temperatures that some exotic metal alloys can.

Similarly, its mechanical strength is lower than steel. For extremely high-pressure applications, the flange's pressure rating must be carefully checked against system requirements.

Mechanical Durability

PTFE is a relatively soft material compared to metal. In environments with high levels of physical abrasion or impact, it may be more susceptible to damage than a steel or alloy equivalent.

Making the Right Choice for Your Application

Selecting the right component requires matching its strengths to your primary operational goal.

- If your primary focus is handling corrosive or aggressive chemicals: PTFE is an outstanding choice due to its chemical inertness, preventing corrosion and extending system life.

- If your primary focus is maintaining product purity (e.g., food, pharma): The non-stick, non-leaching surface of PTFE prevents contamination and ensures clean, consistent flow.

- If your primary focus is maximizing flow with sticky or viscous materials: The low-friction surface is ideal for preventing blockages and maintaining a steady production rate.

- If your primary focus is extreme high-pressure or high-temperature service: You must verify that your system's parameters are within PTFE's specified limits and consider metal alloys if they are not.

Ultimately, choosing a PTFE reducing flange is an investment in system stability and long-term operational performance.

Summary Table:

| Efficiency Benefit | How PTFE Reducing Flanges Deliver |

|---|---|

| Superior Flow Dynamics | Ultra-smooth, non-stick surface minimizes friction and prevents blockages for consistent flow. |

| Enhanced Operational Uptime | Exceptional chemical resistance prevents corrosion and degradation, reducing downtime. |

| Increased System Safety | Creates a reliable, leak-proof seal, enhancing safety and preventing product loss. |

| Application Versatility | Ideal for handling corrosive chemicals, maintaining product purity, and managing viscous materials. |

Ready to enhance your system's efficiency and reliability?

KINTEK specializes in manufacturing high-precision PTFE components, including custom reducing flanges, seals, liners, and labware. Our products are engineered to deliver superior performance in the most demanding semiconductor, medical, laboratory, and industrial applications.

By choosing KINTEK, you benefit from:

- Unmatched Material Expertise: Leverage the full advantages of PTFE for chemical resistance and non-stick properties.

- Precision Manufacturing: Ensure perfect fit and function for seamless integration into your systems.

- Custom Fabrication: Get solutions tailored to your specific needs, from prototypes to high-volume orders.

Invest in long-term performance and reduced downtime. Contact KINTEK today to discuss your project requirements and discover how our PTFE solutions can work for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining