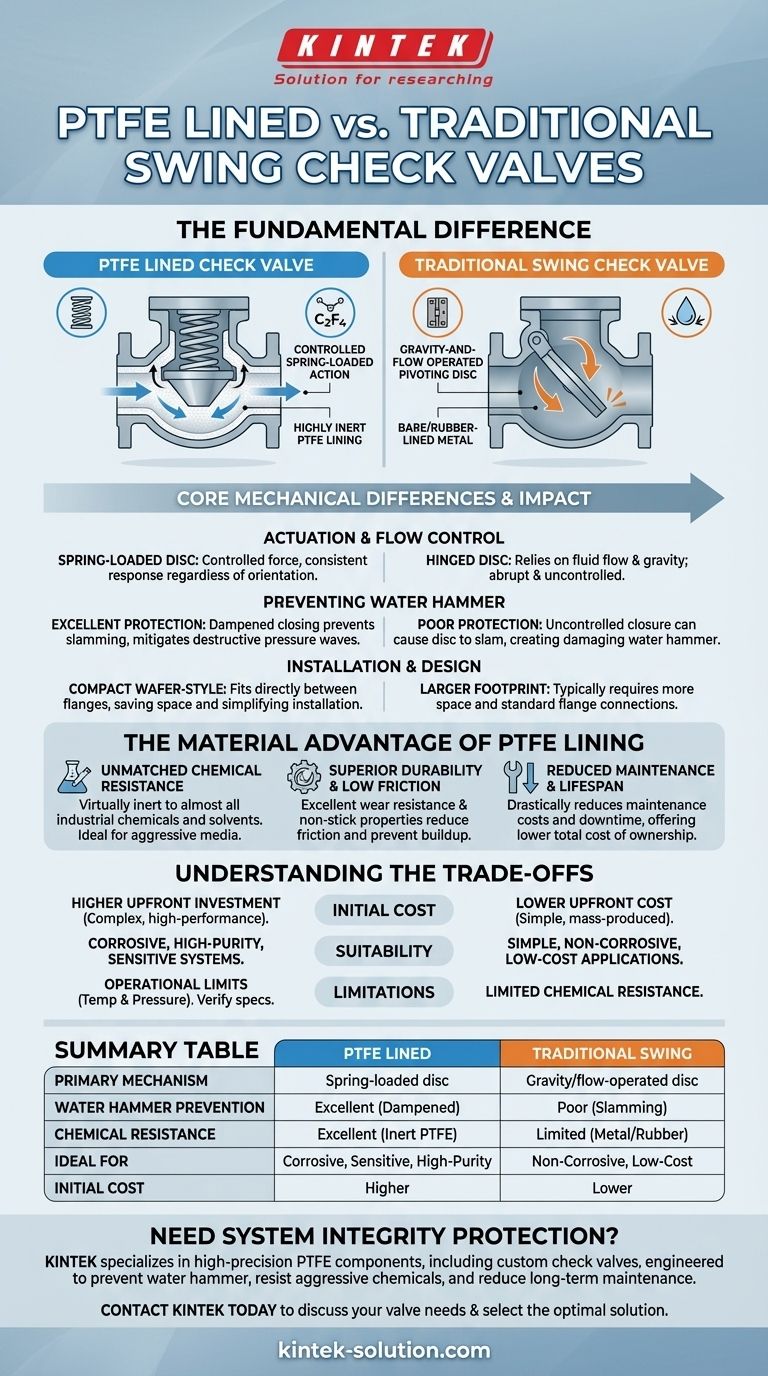

The fundamental difference between a PTFE lined check valve and a traditional swing check valve lies in their core mechanism and material composition. PTFE lined valves use a controlled, spring-loaded action and a highly inert lining, whereas traditional swing check valves rely on a simple gravity-and-flow operated pivoting disc, which is often made of bare or rubber-lined metal.

The choice between these valves is not merely about preventing backflow. It's about selecting a component that either simply performs a function (swing check) or actively protects the entire system's integrity, especially when dealing with corrosive media or pressure-sensitive environments (PTFE lined).

Core Mechanical Differences

The way a valve operates dictates its impact on the entire fluid system. The contrast between these two designs is significant and directly affects system stability and reliability.

Actuation and Flow Control

A PTFE lined check valve typically uses a spring-loaded disc. This spring provides a controlled, predictable force that assists in both opening and closing the valve, ensuring it responds consistently regardless of orientation.

Traditional swing check valves feature a disc mounted on a hinge. It relies entirely on the force of forward fluid flow to open and on gravity or flow reversal to swing shut, which can be an abrupt and uncontrolled action.

Preventing Destructive Water Hammer

The uncontrolled closure of a swing check valve can cause the disc to slam shut when flow suddenly stops or reverses. This creates a damaging pressure wave known as water hammer, which can damage pipes, pumps, and other instruments.

The spring in a PTFE lined valve dampens the closing action. This prevents the disc from slamming, effectively mitigating water hammer and protecting the entire piping system from dangerous pressure spikes.

Installation and Design

Many PTFE lined check valves feature a wafer-style design. This compact form factor allows the valve to be installed directly between two pipe flanges, saving space and simplifying the installation process significantly.

The Material Advantage of PTFE Lining

While the mechanism is a key differentiator, the Polytetrafluoroethylene (PTFE) lining itself provides a distinct set of advantages for demanding applications.

Unmatched Chemical Resistance

PTFE is a fluoropolymer that is virtually inert to almost all industrial chemicals and solvents. This makes PTFE lined valves the superior choice for handling highly corrosive or aggressive fluids that would quickly degrade standard metallic or rubber-lined valves.

Superior Durability and Low Friction

The PTFE lining offers excellent wear resistance and non-stick properties. This reduces friction within the valve, leading to energy savings, and prevents scaling or buildup that can cause other valves to fail over time.

Reduced Maintenance and Lifespan

By resisting corrosion and wear, PTFE lined valves drastically reduce maintenance costs and downtime. Their extended lifespan provides a lower total cost of ownership compared to traditional valves that may require frequent replacement in harsh service.

Understanding the Trade-offs

Choosing the right valve requires an objective look at its limitations and costs relative to the application's demands.

Initial Investment Cost

A PTFE lined check valve is a more complex, high-performance component. As a result, its upfront cost is typically higher than a simple, mass-produced traditional swing check valve.

Application Suitability

For simple, non-corrosive applications like a basic water line, a traditional swing check valve is often perfectly adequate and far more economical. The advanced features of a PTFE lined valve would be unnecessary.

Temperature and Pressure Limitations

While PTFE offers good thermal stability, it has operational limits. In systems with extremely high temperatures or pressures, specialized high-performance metal alloy valves might be required. Always verify the valve's specifications against your system's parameters.

Making the Right Choice for Your System

Your final decision should be based on the specific demands of your fluid system and your long-term operational goals.

- If your primary focus is handling corrosive or high-purity fluids: The chemical inertness of a PTFE lined valve is non-negotiable.

- If your primary focus is protecting sensitive equipment from pressure spikes: The spring-loaded mechanism of a PTFE lined valve is critical for preventing water hammer.

- If your primary focus is minimizing long-term maintenance and downtime: The superior durability of a PTFE lined valve offers a lower total cost of ownership.

- If your primary focus is a low-cost solution for a non-critical, non-corrosive service: A traditional swing check valve is likely the most practical and economical choice.

Ultimately, selecting the right valve is about matching the component's capabilities to the true needs of your system.

Summary Table:

| Feature | PTFE Lined Check Valve | Traditional Swing Check Valve |

|---|---|---|

| Primary Mechanism | Spring-loaded disc for controlled action | Gravity/flow-operated swinging disc |

| Water Hammer Prevention | Excellent (dampened closing) | Poor (can cause slamming) |

| Chemical Resistance | Excellent (virtually inert PTFE lining) | Limited (depends on metal/rubber) |

| Ideal For | Corrosive fluids, sensitive equipment, high-purity systems | Non-corrosive, low-cost applications |

| Initial Cost | Higher | Lower |

Need a valve that protects your system's integrity?

Choosing the right check valve is critical for the performance and longevity of your equipment. At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom check valves, for the semiconductor, medical, laboratory, and industrial sectors.

Our PTFE lined check valves are engineered to:

- Prevent water hammer and protect sensitive instrumentation.

- Resist the most aggressive chemicals, ensuring system purity and safety.

- Reduce long-term maintenance and downtime, providing a superior total cost of ownership.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific application requirements.

Contact KINTEK today to discuss your valve needs and let our experts help you select the optimal solution for your system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability