In terms of sealing performance, a PTFE lined butterfly valve is fundamentally superior to a hard seal butterfly valve. The soft, conformable nature of the PTFE lining allows it to create a bubble-tight, zero-leakage seal against the valve disc. In contrast, hard seal valves, which rely on metal-to-metal contact, are designed for durability under extreme conditions and inherently have a higher potential for minor leakage.

The choice between PTFE lined and hard seal valves is not about which is "better," but about a core engineering trade-off: choosing between the absolute sealing of a soft seal and the extreme durability of a hard seal. Your application's specific demands—not a generic preference—will determine the correct choice.

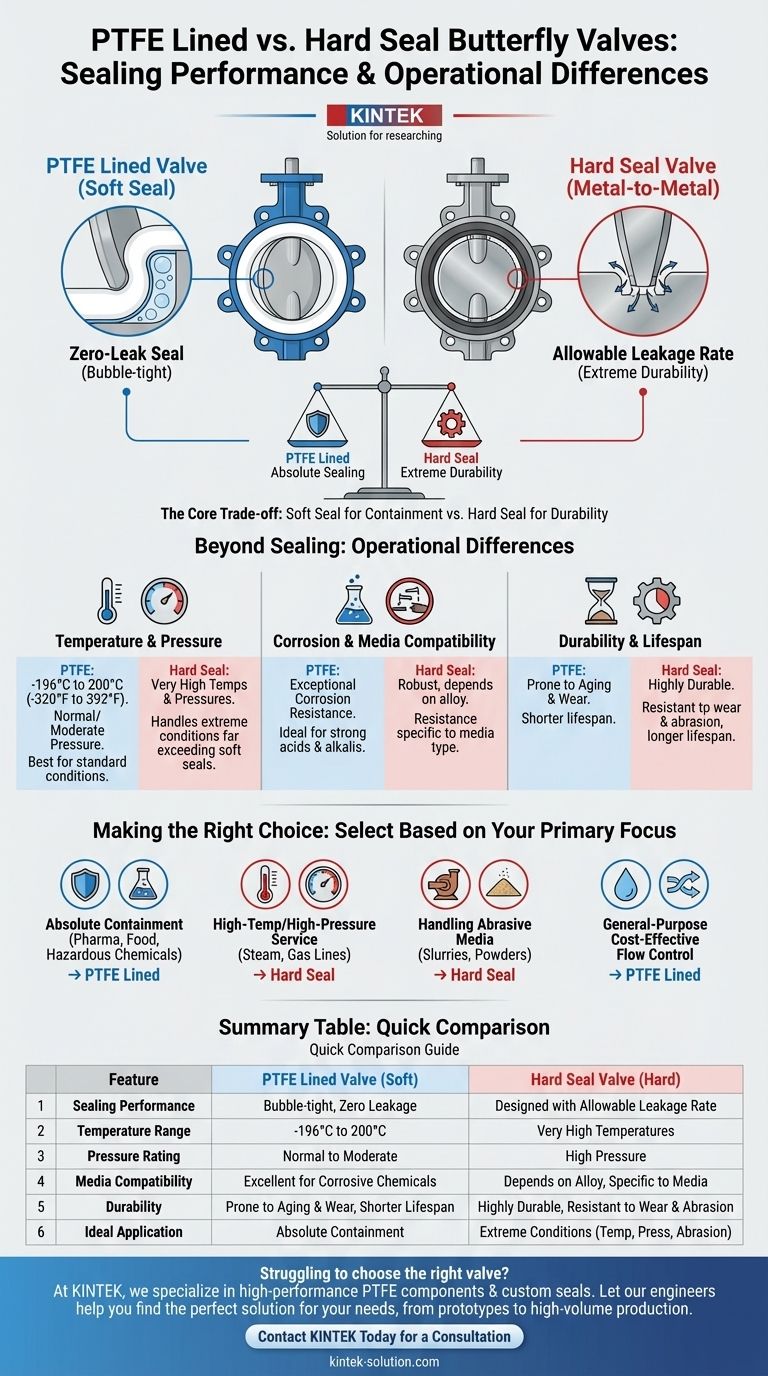

The Core Sealing Mechanism: Soft vs. Hard

The difference in sealing performance comes down to the fundamental properties of the materials used on the sealing surfaces.

How PTFE Valves Achieve a Zero-Leak Seal

A PTFE lined valve functions much like a gasket. The disc closes into the soft, pliable polytetrafluoroethylene (PTFE) seat, deforming it slightly.

This deformation allows the liner to perfectly conform to the edge of the disc, filling any microscopic imperfections and creating a zero-leakage (or bubble-tight) seal. This makes it the ideal choice for applications where absolute containment is critical.

Why Hard Seal Valves Have Inherent Leakage

Hard seal valves use precisely machined metal or other hard material surfaces for both the disc and the seat.

While this manufacturing is highly accurate, it is impossible for two rigid surfaces to create a perfect, void-free seal on a microscopic level. Therefore, these valves are designed and rated for an allowable leakage rate, not for zero leakage.

Beyond Sealing: Key Operational Differences

Sealing is just one factor. The operational environment—temperature, pressure, and media—is equally critical in determining the right valve type.

Temperature and Pressure Resistance

PTFE lined valves have a well-defined, but limited, operational window, typically from -196°C to 200°C (-320°F to 392°F). They are best suited for normal temperature and pressure conditions.

Hard seal valves are built for extremes. Their all-metal construction allows them to handle very high temperatures and pressures far exceeding the limits of any soft-seated valve.

Corrosion and Media Compatibility

PTFE is renowned for its exceptional corrosion resistance, making it the default choice for highly corrosive media like strong acids and alkalis.

Hard seal valves are also robust, often made from stainless steel or exotic alloys. However, their suitability depends entirely on the specific metal's resistance to the chemical media in question.

Durability and Lifespan

The primary weakness of a PTFE lining is that it is prone to aging, wear, and degradation over time, resulting in a shorter service life.

Hard seal valves are significantly more durable and resistant to wear, especially in abrasive applications like slurries. Their robust construction ensures a much longer operational lifespan under harsh physical conditions.

Understanding the Trade-offs

Choosing the wrong valve often happens when one benefit is prioritized without considering its inherent compromises.

The Cost of a Perfect Seal

A PTFE lined valve gives you a perfect seal, but you must accept its limitations. It cannot be used in high-temperature or high-pressure services, and it will require more frequent replacement than a hard seal valve due to material aging.

The Compromise of Durability

A hard seal valve provides longevity and reliability in extreme heat, high pressure, and abrasive flows. The trade-off is accepting a specified, albeit small, leakage rate. This is not a flaw but a designed-in characteristic for applications where durability outweighs the need for a bubble-tight seal.

Making the Right Choice for Your Application

Select your valve based on the single most critical demand of your system.

- If your primary focus is absolute containment: Choose a PTFE lined valve for its zero-leakage sealing, ideal for hazardous chemicals, pharmaceuticals, or food-grade applications.

- If your primary focus is high-temperature or high-pressure service: Choose a hard seal valve specifically rated for the extreme conditions of your system, such as in steam or high-pressure gas lines.

- If your primary focus is handling abrasive media: Choose a hard seal valve for its superior wear resistance against slurries, powders, or other media with suspended solids.

- If your primary focus is general-purpose, cost-effective flow control: A PTFE lined valve is often the best choice for standard water, air, or chemical lines at normal temperatures and pressures.

Ultimately, an informed valve selection is made by precisely matching the valve's strengths to your application's non-negotiable requirements.

Summary Table:

| Feature | PTFE Lined Valve | Hard Seal Valve |

|---|---|---|

| Sealing Performance | Bubble-tight, zero leakage | Designed with an allowable leakage rate |

| Temperature Range | -196°C to 200°C | Very high temperatures (e.g., steam lines) |

| Pressure Rating | Normal to moderate | High pressure |

| Media Compatibility | Excellent for corrosive chemicals (acids, alkalis) | Depends on alloy; robust but specific to media |

| Durability | Prone to aging and wear; shorter lifespan | Highly durable, resistant to wear and abrasion |

| Ideal Application | Absolute containment (pharma, food, hazardous chemicals) | Extreme conditions (high temp/pressure, abrasive slurries) |

Struggling to choose the right valve for your specific needs?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom seals and liners for critical applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a solution that perfectly balances sealing performance, durability, and chemical resistance for your unique operational demands.

Let our engineers help you make the right choice—from prototypes to high-volume production. Contact us today for a consultation and get a valve solution you can rely on!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability