In food and beverage production, PTFE expansion joints are essential for preserving product purity and ensuring operational reliability. Their unique material properties allow them to handle the dual demands of stringent sanitation and the physical stresses of manufacturing, making them a cornerstone of modern food-grade piping systems.

The core value of PTFE expansion joints in the food and beverage industry lies in a simple fact: they are chemically inert and non-stick. This unique combination ensures that nothing from the joint leaches into the product and no product sticks to the joint, guaranteeing both safety and efficiency.

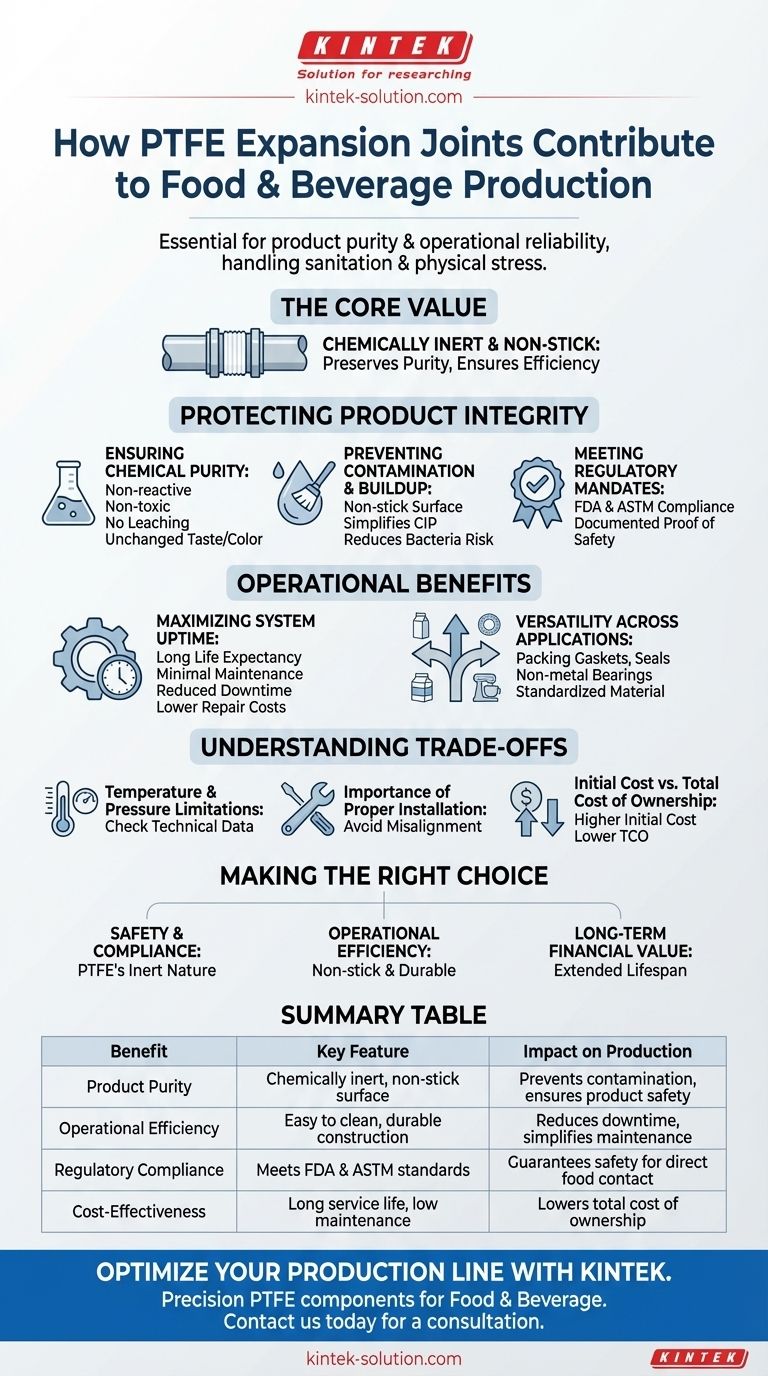

The Core Function: Protecting Product Integrity

The primary role of any component in a food or beverage line is to do no harm. PTFE, or Polytetrafluoroethylene, is engineered to excel at this, serving as a protective barrier within the system.

Ensuring Chemical Purity

PTFE is fundamentally non-reactive and non-toxic. It does not corrode, break down, or leach chemicals when it comes into contact with food products, cleaning agents, or sanitizers.

This inert nature ensures the final product's taste, color, and composition remain unchanged, preserving the purity that is critical for brand reputation and consumer safety.

Preventing Contamination and Buildup

The material's famously non-stick surface is a significant operational advantage. It prevents food particles, greases, and other residues from adhering to the joint's surface.

This property drastically simplifies clean-in-place (CIP) procedures, reduces the risk of bacterial growth, and ensures a smooth, uninterrupted flow through the system.

Meeting Strict Regulatory Mandates

Compliance is non-negotiable in this industry. PTFE expansion joints are manufactured to meet stringent safety and hygiene standards, including FDA and ASTM compliance.

Using certified components provides documented proof that the system is built with materials deemed safe for direct food contact, satisfying both internal quality control and external auditors.

Translating Properties into Operational Benefits

Beyond safety and compliance, PTFE expansion joints deliver tangible improvements to the efficiency and cost-effectiveness of a production facility.

Maximizing System Uptime

These components are exceptionally tough and resistant to the stressors of a manufacturing environment, such as vibration, pressure changes, and thermal cycling.

Their durability translates directly to a long life expectancy and minimal maintenance requirements. This robust performance significantly reduces system downtime and lowers the frequency of costly repairs. As seen in similar demanding industries, this can lead to maintenance cost reductions of 40% or more.

Versatility Across Applications

PTFE's reliability makes it suitable for a wide range of uses. It is found in packing and envelope gaskets in dairy and beverage lines, seals for pressure vessels, and even in non-metal bearings for mixers where grease is prohibited.

This versatility allows engineers to standardize on a single, trusted material for multiple critical applications, simplifying inventory and maintenance protocols.

Understanding the Trade-offs

While PTFE is a superior material for these applications, a complete technical assessment requires acknowledging its operational boundaries.

Temperature and Pressure Limitations

Every material has its limits. While PTFE handles a very wide range of temperatures and pressures common in food production, extreme or unusual process conditions must be evaluated against the specific joint's technical data sheet to ensure safe operation.

Importance of Proper Installation

The effectiveness of any expansion joint is highly dependent on correct installation. Improper bolt torque or system misalignment can compromise the seal, negating the benefits of the material itself and potentially creating a failure point.

Initial Cost vs. Total Cost of Ownership

PTFE components may have a higher initial purchase price compared to some elastomer or metal alternatives. However, this is almost always offset by a lower total cost of ownership due to reduced maintenance, less frequent replacement, and the elimination of downtime related to joint failure.

Making the Right Choice for Your Goal

When selecting expansion joints, your decision should be guided by your primary operational priority.

- If your primary focus is product safety and compliance: PTFE's inert nature and FDA compliance make it the most reliable choice for eliminating contamination risks.

- If your primary focus is operational efficiency: The material's non-stick surface simplifies cleaning while its durability minimizes maintenance, directly boosting uptime.

- If your primary focus is long-term financial value: PTFE's extended lifespan and reliability deliver a superior return on investment by drastically reducing repair costs and production losses.

Ultimately, choosing PTFE expansion joints is an investment in the safety, consistency, and efficiency of your entire production line.

Summary Table:

| Benefit | Key Feature | Impact on Production |

|---|---|---|

| Product Purity | Chemically inert, non-stick surface | Prevents contamination, ensures product safety |

| Operational Efficiency | Easy to clean, durable construction | Reduces downtime, simplifies maintenance |

| Regulatory Compliance | Meets FDA & ASTM standards | Guarantees safety for direct food contact |

| Cost-Effectiveness | Long service life, low maintenance | Lowers total cost of ownership |

Optimize your production line with high-performance PTFE components from KINTEK.

Our precision-manufactured PTFE expansion joints, seals, and labware are engineered to meet the stringent demands of the food and beverage, semiconductor, medical, and laboratory industries. We ensure product purity, operational reliability, and compliance with critical standards.

Whether you need a custom prototype or a high-volume order, KINTEK delivers the quality and performance you need to protect your product and your process.

Contact KINTEK today to discuss your specific application and receive a expert consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key material properties of PTFE that make it suitable for expansion joints? Ensure Long-Term Reliability in Demanding Systems

- What are the key design features of PTFE bushings? Achieve Maintenance-Free, High-Performance Bearing Solutions

- What machining processes can be used for PTFE? Master CNC Turning, Milling & Drilling

- What are the key advantages of using PTFE valves in the chemical industry? Enhance Safety and Purity

- What are some innovative applications of CNC machined PTFE in product design? Unlock Extreme Performance in Medical, Aerospace & Electronics

- Describe the PTFE injection molding process and its optimization strategies. Master Complex PTFE Part Production

- What medical benefits does PTFE's low friction and non-stick surface provide? Minimize Patient Trauma & Complications

- Under what conditions is the coefficient of friction minimized in PTFE slide bearings? Optimize for Low Friction