At their core, PTFE bellows seals and pusher seals differ in how they accommodate wear and movement. A PTFE bellows seal uses a flexible, corrugated membrane (the bellows) to allow for movement, keeping its secondary seal static and fixed in place. In contrast, a pusher seal relies on a spring to push a dynamic secondary seal (like an O-ring) along the shaft to maintain contact as the primary seal faces wear.

The fundamental choice between these two designs comes down to reliability. A PTFE bellows seal eliminates the sliding secondary seal, which is a common point of failure in pusher seals due to shaft fretting and hang-up.

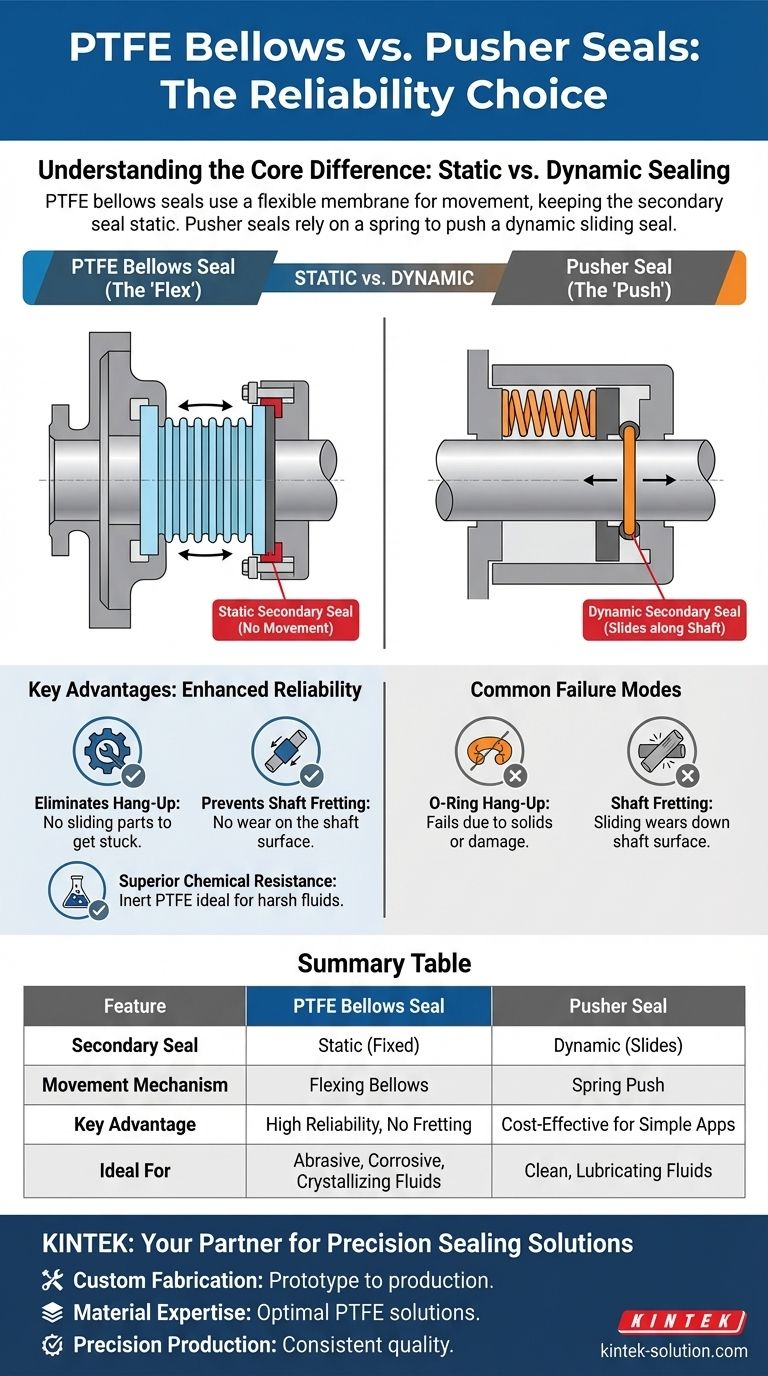

The Fundamental Design Difference: Static vs. Dynamic Sealing

To understand the practical implications, you must first visualize how each seal maintains contact and prevents leaks under dynamic conditions.

How a Pusher Seal Works (The 'Push')

A pusher seal is a multi-part assembly, with its most critical components being a primary seal face, a mating ring, a spring, and a secondary seal (typically an elastomer O-ring).

The spring provides the closing force, "pushing" the primary seal face against the mating ring to create the main seal.

Crucially, the secondary O-ring must slide along the pump shaft or sleeve to compensate for seal face wear and any shaft misalignment. This sliding motion is the defining characteristic—and the primary weakness—of the pusher design.

How a PTFE Bellows Seal Works (The 'Flex')

A PTFE bellows seal integrates the secondary seal and the spring mechanism into a single, cohesive unit—the bellows itself.

The secondary seal is clamped onto the shaft or sleeve and does not move. It remains static throughout the seal's operational life.

All axial movement required to compensate for wear and shaft motion is handled by the flexing of the corrugated bellows. This design eliminates any sliding friction at the critical secondary sealing point.

Practical Implications of the Design

The difference between a "push" and a "flex" mechanism has significant consequences for seal reliability and application range.

Reliability and Failure Modes

The single greatest advantage of a PTFE bellows seal is its enhanced reliability. It eliminates the failure modes associated with the pusher seal's dynamic secondary seal.

Pusher Seal Hang-Up: The sliding O-ring in a pusher seal can get stuck or "hang up" due to solids in the fluid, chemical attack, or shaft damage. When it hangs up, it can no longer compensate for wear, leading to immediate seal failure.

Shaft Fretting: The constant, minute back-and-forth movement of the secondary O-ring abrades and wears down the shaft surface, a phenomenon known as fretting. This damages the shaft and can eventually create a leak path under the O-ring.

A PTFE bellows seal avoids both of these problems entirely because its secondary seal is static. There is no sliding, no hang-up, and no fretting.

Handling of Abrasives and Corrosives

PTFE (Polytetrafluoroethylene) is an advanced polymer known for its extreme chemical inertness and low-friction properties.

The bellows design, constructed from a solid block of machined PTFE, has no small crevices for abrasive particles or crystallizing fluids to clog. This makes it inherently superior for slurries and aggressive chemical services where a pusher seal's O-ring and spring would quickly fail.

The Role of Springs

While the bellows itself provides a spring-like force, many high-performance PTFE bellows seals also incorporate a metallic spring to ensure consistent pressure on the seal faces. Unlike in a pusher seal where the spring energizes a sliding component, here it simply assists the flex of the non-sliding bellows.

Understanding the Trade-offs

No single design is perfect for every situation. Choosing the right seal requires understanding the potential limitations.

Pressure and Temperature Limits

While robust, the flexible bellows structure can be the limiting factor for very high-pressure applications where distortion may become a concern. The material properties of PTFE also define its operational temperature window.

Cost and Complexity

PTFE bellows seals are a more engineered solution, precision-machined from high-performance materials. As such, their upfront cost is typically higher than that of a standard, mass-produced elastomeric pusher seal.

Installation Sensitivity

The integrity of a bellows seal relies on the proper static installation of its tail-end on the shaft or sleeve. While not overly complex, it requires careful attention during setup to ensure a leak-tight fit. A simple pusher seal can sometimes be more forgiving of minor installation errors in non-critical applications.

Making the Right Choice for Your Application

Your decision should be driven by the demands of the service fluid and your operational priorities.

- If your primary focus is reliability in demanding services (corrosives, slurries, crystallizing fluids): The PTFE bellows seal is the superior choice because its static secondary seal design eliminates fretting and hang-up.

- If your primary focus is a general-purpose, cost-effective solution for clean, lubricating fluids: A pusher seal can be an adequate and economical choice, provided shaft fretting from high speeds or vibration is not a primary concern.

Ultimately, choosing the right seal is about matching the design's inherent strengths to the specific challenges of your application.

Summary Table:

| Feature | PTFE Bellows Seal | Pusher Seal |

|---|---|---|

| Secondary Seal | Static (Fixed) | Dynamic (Slides along shaft) |

| Movement Mechanism | Flexing of the bellows | Spring pushes seal faces |

| Key Advantage | High reliability, no hang-up or fretting | Cost-effective for simple applications |

| Ideal For | Abrasive slurries, corrosive chemicals, crystallizing fluids | Clean, lubricating, non-abrasive fluids |

| Common Failure Modes | Bellows fatigue (rare) | Secondary seal hang-up, shaft fretting |

Struggling with seal failures in harsh conditions? The right PTFE component is critical for reliability in semiconductor, medical, laboratory, and industrial applications.

At KINTEK, we specialize in precision-manufactured PTFE seals, bellows, liners, and custom labware. Our expertise ensures your equipment handles corrosive, abrasive, and high-purity environments with maximum uptime.

We provide:

- Custom Fabrication: From prototype to high-volume production.

- Material Expertise: Optimal PTFE solutions for your specific chemical and physical demands.

- Precision Production: Consistent quality for critical applications.

Let's solve your sealing challenge together. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How are PTFE lined butterfly valves assembled with bolts? A Guide to Secure, Leak-Free Installation

- What are some common configurations of Teflon back-up rings? Achieve Superior O-Ring Support and Extrusion Resistance

- Why are PTFE oil seals considered a superior choice for many applications? Unlock Reliability in Extreme Conditions

- Why is virgin PTFE particularly suitable for food and medical applications? Ensuring Purity and Safety

- How is Teflon used in the aerospace industry? Essential for Seals, Coatings & Insulation

- What industries benefit from PTFE's non-stick properties? Boost Efficiency and Purity

- How is the PTFE lining process carried out? A Guide to Flawless Corrosion Protection

- How do PTFE spring-energized seals perform in defense and nuclear environments? Engineered for Extreme Reliability.