At their core, Polytetrafluoroethylene (PTFE) bearing pads enhance structural safety and efficiency by creating a high-load, low-friction interface that decouples a structure from its foundation. This allows for controlled movement, dissipates harmful energy from forces like thermal expansion or seismic activity, and prevents the buildup of destructive stress within the structure itself.

The crucial insight is that PTFE bearing pads are not simply passive supports. They are engineered components designed to actively manage dynamic forces, transforming large, rigid structures into systems that can safely flex and move as environmental conditions change.

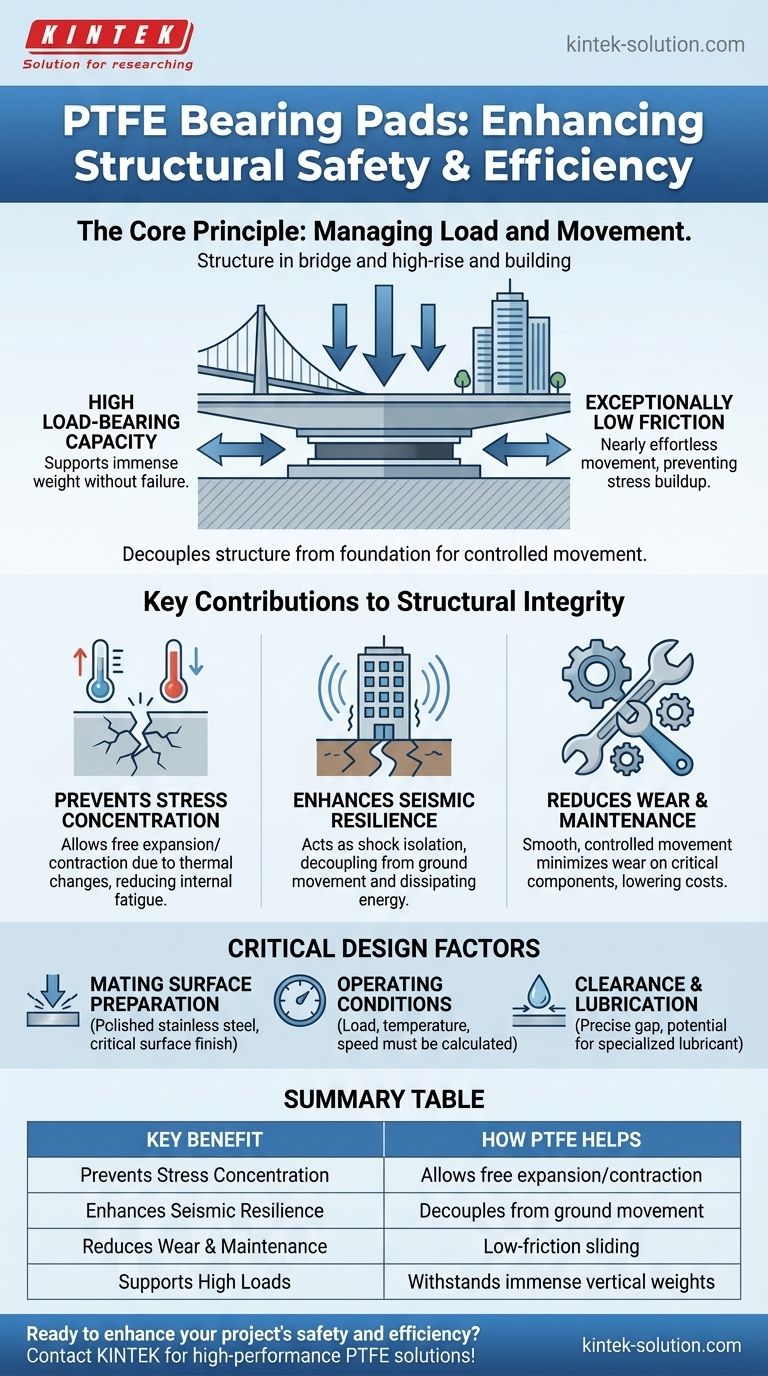

The Core Principle: Managing Load and Movement

The effectiveness of PTFE bearing pads hinges on a unique combination of material properties that allow them to handle two seemingly contradictory tasks: supporting immense weight while allowing for nearly effortless horizontal movement.

Exceptionally Low Friction

PTFE possesses one of the lowest coefficients of friction of any solid material. This property is fundamental to its function in a bearing pad.

It allows massive structural elements, like a bridge deck, to slide smoothly with minimal resistance. This prevents the transfer of horizontal forces into the supporting columns or abutments.

High Load-Bearing Capacity

Despite its slick surface, PTFE can be engineered to withstand enormous compressive loads.

This ensures the pad can support the vertical weight of a high-rise building or stadium roof without failing, while the low-friction surface remains ready to accommodate movement.

Accommodating Environmental Forces

The primary purpose of a structural bearing is to manage movement caused by external forces.

PTFE pads are critical for managing the daily expansion and contraction of materials due to temperature changes. They also serve as a vital component in seismic isolation systems, allowing a building to move independently of ground shaking.

Key Contributions to Structural Integrity

By separating load from movement, PTFE pads provide tangible benefits that directly translate to safer, more efficient, and longer-lasting structures.

Preventing Stress Concentration

When a structure cannot move, forces like thermal expansion create immense internal stress. This stress concentrates in joints and structural members, leading to fatigue and potential failure.

PTFE pads provide a release valve for this stress, allowing the structure to expand and contract freely, which is critical for the long-term health of bridges and large buildings.

Enhancing Seismic Resilience

In an earthquake, the most damaging forces are often the rapid, horizontal ground movements.

PTFE bearing pads can act as a shock isolation system. They create a sliding surface that decouples the superstructure from its foundation, absorbing and dissipating seismic energy instead of transferring it directly into the building's frame.

Reducing Wear and Maintenance

The smooth, controlled movement facilitated by PTFE pads reduces wear and tear on the primary structural components.

By absorbing these small but constant movements, the bearing pads protect more critical and expensive parts of the structure from fatigue, leading to increased efficiency and lower lifetime maintenance costs.

Understanding the Critical Design Factors

The exceptional performance of a PTFE bearing is not automatic; it is the result of a carefully engineered system. The pad itself is only one part of the equation, and failure to consider the entire system can compromise its effectiveness.

Mating Surface Preparation

The performance of a PTFE bearing is directly dependent on the surface it slides against, which is typically a highly polished stainless steel plate.

The hardness and surface finish of this hardware are critical. An improperly prepared surface will increase friction and can abrade the PTFE, severely reducing the bearing's lifespan and effectiveness.

Operating Conditions

The load, temperature, and speed of movement all influence the performance of the bearing.

These factors must be precisely calculated during the design phase to ensure the correct grade of PTFE and bearing design are specified for the application's unique demands.

The Role of Clearance and Lubrication

The gap, or radial clearance, between moving components is a critical design parameter. An incorrect clearance can lead to the extrusion of the PTFE material under load.

While PTFE is self-lubricating, some designs incorporate dimples on the surface to hold a specialized lubricant, further reducing the friction coefficient for highly demanding applications.

Making the Right Choice for Your Goal

The specific application will dictate the most important features of the bearing pad.

- If your primary focus is managing thermal expansion in a long-span bridge: The exceptionally low coefficient of friction is the most critical factor to prevent stress buildup in the superstructure.

- If your primary focus is seismic performance for a building: The ability of the pad to provide buffering and shock isolation by decoupling the structure from the ground is paramount.

- If your primary focus is supporting a complex structure with high loads and rotational needs (e.g., a stadium roof): The combination of high vertical load capacity and the ability to accommodate multi-directional movement is the key design driver.

Ultimately, specifying the correct PTFE bearing system is a critical engineering decision that enhances the safety and longevity of any major structure.

Summary Table:

| Key Benefit | How PTFE Bearing Pads Help |

|---|---|

| Prevents Stress Concentration | Allows structures to expand/contract freely, reducing internal fatigue. |

| Enhances Seismic Resilience | Decouples structures from ground movement, dissipating seismic energy. |

| Reduces Wear & Maintenance | Low-friction sliding minimizes wear on critical structural components. |

| Supports High Loads | Engineered to withstand immense vertical weights without failure. |

Ready to enhance your project's safety and efficiency with precision-engineered PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, bearing pads, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components that meet exact specifications for load, friction, and durability.

Contact us today to discuss how our PTFE solutions can contribute to your structural integrity goals!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments