To be precise, there is no difference in the core material or its applications. The confusion arises because Teflon is simply the registered trademark name for a material called Polytetrafluoroethylene, or PTFE. The terms are often used interchangeably, much like referring to all facial tissues as "Kleenex," where the application of the product remains identical regardless of what you call it.

The search for different applications between PTFE and Teflon is based on a common misunderstanding. The key is to recognize you are not comparing two different materials, but rather a generic chemical compound (PTFE) against a well-known brand name (Teflon) that sells that exact compound.

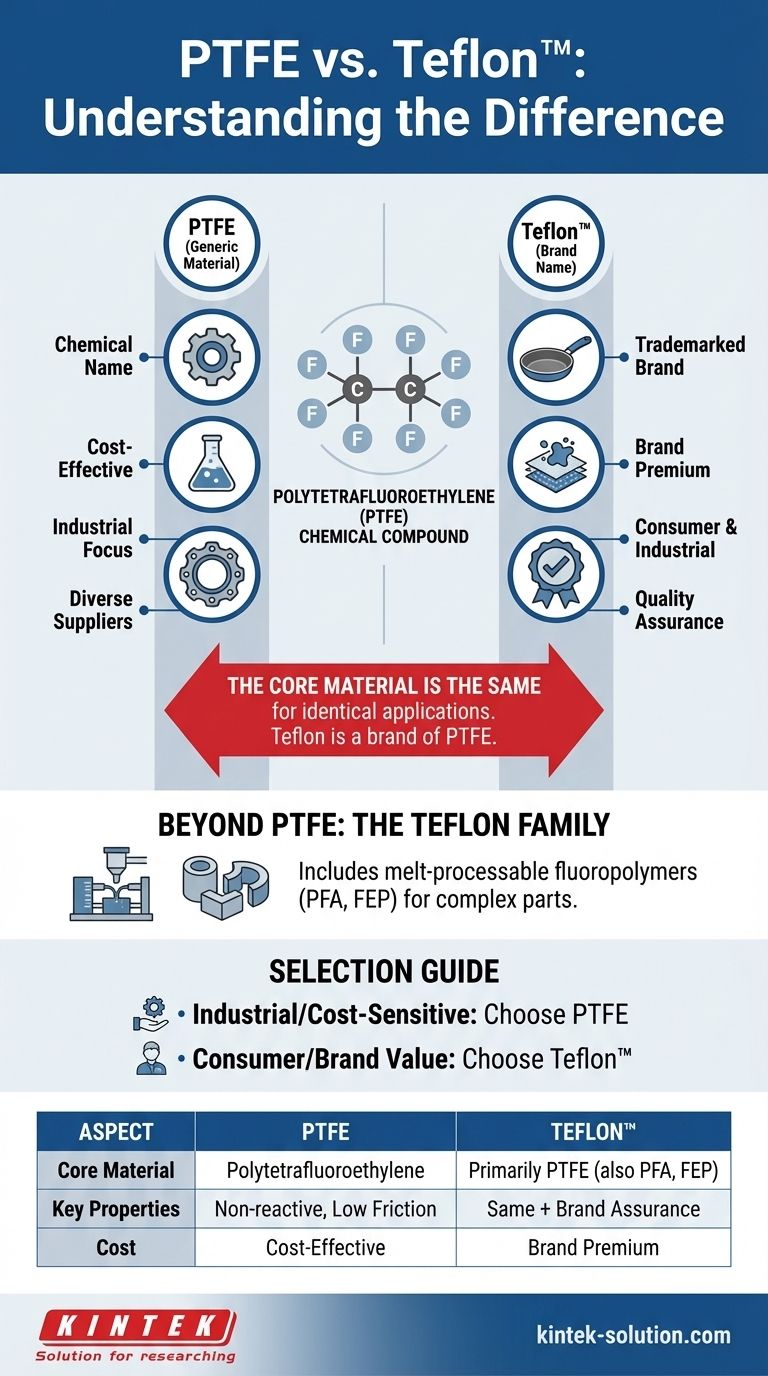

The Fundamental Misconception: Material vs. Brand

The root of this question is a simple but pervasive mix-up between a material's scientific name and its commercial brand name. Understanding this distinction is the first step toward making an informed decision.

What is PTFE?

PTFE, or Polytetrafluoroethylene, is the specific chemical name for a synthetic fluoropolymer of tetrafluoroethylene.

It is known for its remarkable properties: it's extremely non-reactive, has a very high melting point, and possesses one of the lowest coefficients of friction of any solid. These properties make it inherently suitable for a vast range of applications.

What is Teflon™?

Teflon™ is a trademarked brand name, originally established by DuPont and now owned by Chemours.

While Teflon is most famous for its PTFE-based products (like non-stick cookware coatings), the brand actually encompasses a family of related fluoropolymer materials, not just PTFE.

The relationship is simple: all Teflon is a fluoropolymer, but not all of it is strictly PTFE. However, when people refer to "Teflon," they are most often thinking of PTFE.

Why the Confusion About Applications?

The perception that PTFE is for industrial use and Teflon is for consumer goods is purely a result of marketing and brand recognition.

Chemours heavily markets its Teflon™ brand for consumer applications like cookware and stain-resistant fabrics. Meanwhile, industrial suppliers will typically list the generic material "PTFE" in their catalogs for applications like gaskets, seals, and chemical linings.

The underlying material—PTFE—is the same in both cases and is equally suited for either application.

Beyond PTFE: The Teflon Family of Products

While the most common Teflon product is indeed PTFE, the brand name can be a source of confusion because it is also used for other materials with slightly different properties.

The Role of PFA and FEP

The Teflon™ brand also includes other fluoropolymers like PFA (Perfluoroalkoxy alkanes) and FEP (Fluorinated ethylene propylene).

These materials share many of PTFE's desirable properties but are melt-processable, meaning they can be more easily formed into complex shapes using conventional injection molding and extrusion techniques. Pure PTFE cannot be processed this way.

How This Affects Material Selection

This is the only area where a "Teflon" product might have different applications than generic PTFE.

If a product is labeled "Teflon," it is crucial to confirm which specific fluoropolymer it is made from. If it is Teflon™ PTFE, its applications are identical to any generic PTFE. If it is Teflon™ PFA or FEP, it was likely chosen for its unique processing advantages.

Understanding the Practical Trade-offs

When comparing generic PTFE to Teflon™ branded PTFE, the decision comes down to factors beyond the material's physical properties.

Cost Implications

Branded Teflon™ products are often more expensive than their generic PTFE counterparts. This premium is for the brand name, its associated marketing, and the reputation for consistent quality control.

Performance is Identical

For a given specification, there is no performance difference between a gasket made of generic PTFE and one made of Teflon™ PTFE. They will have the same chemical resistance, temperature range, and coefficient of friction.

Brand Recognition and Trust

In certain industries or consumer markets, the Teflon™ brand carries significant weight. Using the branded material can simplify compliance and instill consumer confidence, which may justify the additional cost.

Making the Right Choice for Your Application

Choosing between generic PTFE and a branded product depends entirely on your project's specific goals and constraints.

- If your primary focus is sourcing a non-stick, chemically inert material for an industrial part: Specify the material as PTFE. You can then treat Teflon™ as one potential supplier among many others.

- If your primary focus is cost-effectiveness for a high-volume application: Generic PTFE will almost always provide the same performance for a lower cost.

- If your primary focus is marketing a consumer product: Using the Teflon™ brand name can offer a significant advantage due to its high public recognition and association with quality.

- If your primary focus is creating a complex shape that requires injection molding: Look specifically for melt-processable fluoropolymers like PFA or FEP, which may be sold under the Teflon™ brand or other trade names.

Ultimately, your choice is not about differing applications, but about balancing the universal properties of PTFE against the cost and market value of a brand name.

Summary Table:

| Aspect | PTFE (Generic Material) | Teflon™ (Brand Name) |

|---|---|---|

| Core Material | Polytetrafluoroethylene | Primarily PTFE, but also includes PFA, FEP |

| Key Properties | Non-reactive, high heat resistance, low friction | Same as PTFE, plus brand assurance |

| Common Applications | Industrial seals, gaskets, labware, liners | Non-stick cookware, consumer goods, industrial parts |

| Cost | Generally more cost-effective | Often carries a brand premium |

| Selection Guide | Ideal for cost-sensitive industrial applications | Preferred when brand recognition adds value |

Need High-Performance PTFE Components?

Understanding the nuances of PTFE and Teflon is the first step. The next is sourcing precision-manufactured components that meet your exact specifications.

KINTEK specializes in the custom fabrication of PTFE parts—whether you refer to the material as PTFE or are looking for Teflon™-grade quality. We serve the semiconductor, medical, laboratory, and industrial sectors with:

- Precision Production: Ensuring every seal, liner, or piece of labware performs reliably.

- Custom Fabrication: From initial prototypes to high-volume orders, we tailor solutions to your unique requirements.

- Expert Material Guidance: We help you select the right fluoropolymer—be it PTFE, PFA, or FEP—for your application's specific needs, balancing performance, processability, and cost.

Let's discuss your project requirements. Contact KINTEFL today for a quote and expert support.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key qualities of PTFE material? Unlock Extreme Chemical, Thermal & Electrical Resistance

- How does the temperature range of RPTFE compare to other PTFE materials? Maximize Performance Under Load

- What types of clothing incorporate Teflon? Discover High-Performance Protective Apparel

- How can PTFE properties be enhanced? Improve Wear, Strength, and Creep Resistance with Fillers

- What are the key structural components of Teflon? Unlocking the Secrets of PTFE's Performance

- What are the key benefits of expanded PTFE? Superior Sealing, Medical, & Industrial Performance

- What medical applications benefit from PTFE? A Guide to Its Critical Role in Healthcare

- What is the chemical name for Teflon, and what is its abbreviation? Unveiling PTFE’s Unique Properties