At its core, the choice between metal and PTFE bellows comes down to a fundamental trade-off. Metal bellows are engineered for mechanical strength in high-pressure and high-temperature environments, whereas PTFE bellows provide superior chemical resistance and greater flexibility for dynamic systems.

The decision is not about which material is universally better, but which one possesses the specific properties required to meet the primary challenge of your application—be it extreme physical force or aggressive chemical exposure.

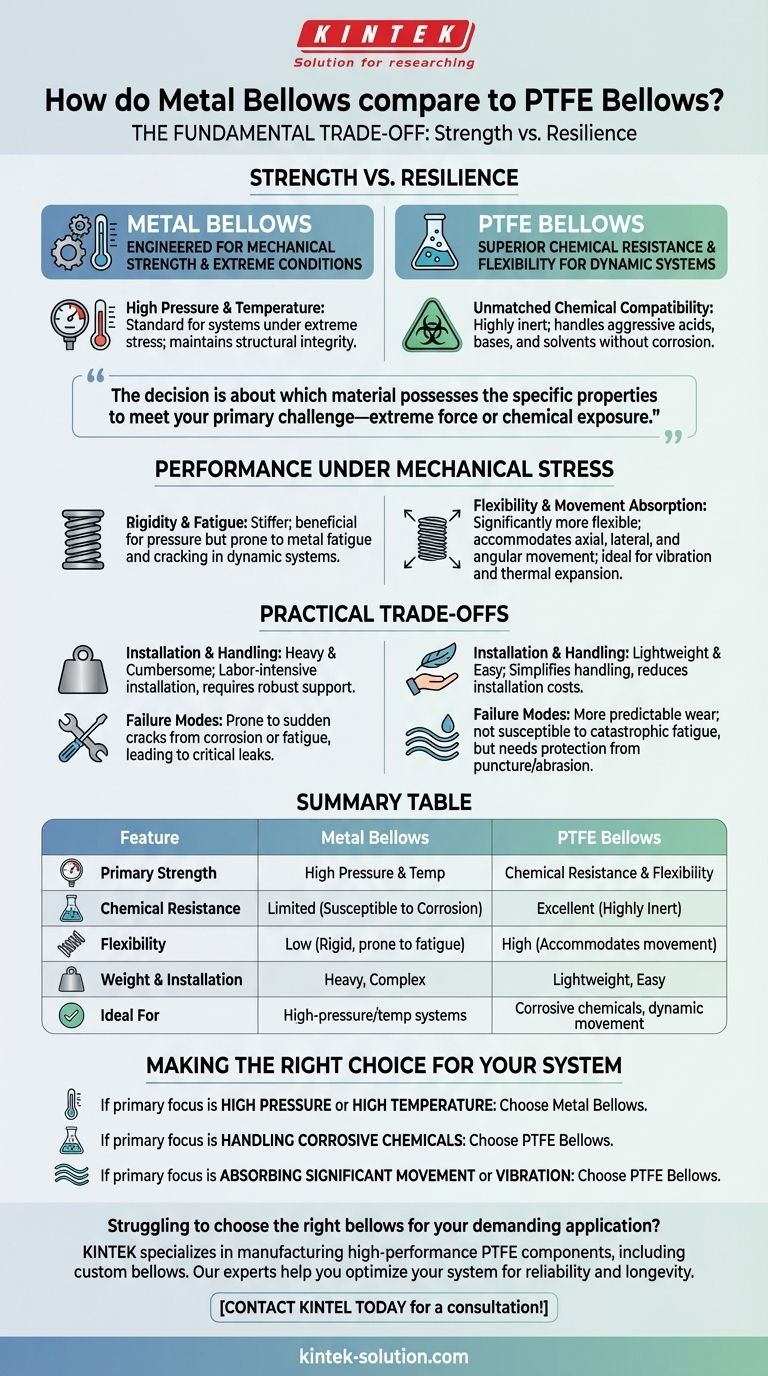

The Fundamental Divide: Strength vs. Resilience

The primary difference between these two materials lies in how they handle operational stressors. Metal excels at resisting physical force, while PTFE excels at resisting chemical attack.

Pressure and Temperature Handling

Metal bellows are the standard for systems operating under high pressure and extreme temperatures. Their inherent rigidity and the strength of materials like stainless steel or Inconel allow them to maintain structural integrity under conditions that would compromise other materials.

Chemical Compatibility

PTFE bellows offer unmatched chemical resistance. As one of the most inert materials available, PTFE can handle a vast range of aggressive acids, bases, and solvents without corroding or degrading, making it essential for chemical processing, pharmaceutical, and food-grade applications where purity is critical. Metal, in contrast, is susceptible to corrosion from specific chemicals, which can lead to premature failure.

Performance Under Mechanical Stress

Beyond simple environmental resistance, how a bellows responds to movement is a critical factor in its selection and longevity.

Flexibility and Movement Absorption

PTFE is significantly more flexible than metal. This allows PTFE bellows to accommodate greater degrees of axial, lateral, and angular movement. They are exceptionally well-suited for systems with thermal expansion, vibration, or slight misalignments.

Rigidity and Fatigue

Metal bellows are much stiffer and less tolerant of dynamic movement. While this rigidity is beneficial for maintaining pressure, it can become a liability in systems with frequent cycling or vibration, potentially leading to metal fatigue and stress cracking over time.

Understanding the Practical Trade-offs

The differences in material properties extend to real-world considerations like installation, cost, and long-term reliability.

Installation and Handling

PTFE bellows are lightweight and significantly easier to install. Their low weight simplifies handling, reduces the need for heavy lifting equipment, and can lower overall labor and installation costs.

Metal bellows, by comparison, are heavy and cumbersome. Their installation is often a more labor-intensive process, requiring more robust support structures and careful alignment to prevent premature stress.

Failure Modes

The typical failure mode for metal bellows is often a crack due to corrosion or fatigue, which can result in a sudden and critical leak. PTFE bellows tend to have a more predictable wear life and are not susceptible to the same type of catastrophic fatigue failure, though care must be taken to protect them from physical puncture or abrasion.

Making the Right Choice for Your System

Your system's specific operating conditions and primary demands will clearly point to the correct material.

- If your primary focus is high pressure or high temperature: Metal bellows provide the essential mechanical strength and thermal stability required for safe operation.

- If your primary focus is handling corrosive chemicals: PTFE bellows are the definitive choice for their chemical inertness, ensuring system longevity and preventing contamination.

- If your primary focus is absorbing significant pipe movement or vibration: The superior flexibility of PTFE bellows makes them the ideal solution for maintaining system integrity.

By identifying your system's most critical demand, you can confidently select the material that ensures reliable and long-term performance.

Summary Table:

| Feature | Metal Bellows | PTFE Bellows |

|---|---|---|

| Primary Strength | High Pressure & Temperature | Chemical Resistance & Flexibility |

| Chemical Resistance | Limited (Susceptible to Corrosion) | Excellent (Highly Inert) |

| Flexibility | Low (Rigid, prone to fatigue) | High (Accommodates movement) |

| Weight & Installation | Heavy, Complex | Lightweight, Easy |

| Ideal For | High-pressure/temperature systems | Corrosive chemicals, dynamic movement |

Struggling to choose the right bellows for your demanding application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom bellows, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a solution perfectly tailored to handle your specific chemical, pressure, and movement requirements.

Let our material experts help you optimize your system for reliability and longevity. Contact KINTEL today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What materials are used in Teflon encapsulation for O-rings? A Guide to FEP & PFA Jackets

- What industries benefit the most from PTFE expansion bellows? Maximize Safety and Purity in Harsh Environments

- In what types of cables is PTFE commonly used? For High-Performance Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the challenges and recommendations for machining Teflon? Master Precision PTFE Fabrication

- What other specialized applications use PTFE lip seals? Ensure Reliability in Aerospace, Medical, and Automotive Systems

- Why are PTFE lined butterfly valves popular in industrial applications? Unmatched Chemical Resistance & Reliability

- Why are PTFE energized seals a preferred choice for aerospace engineers? Ensure Reliability in Extreme Conditions