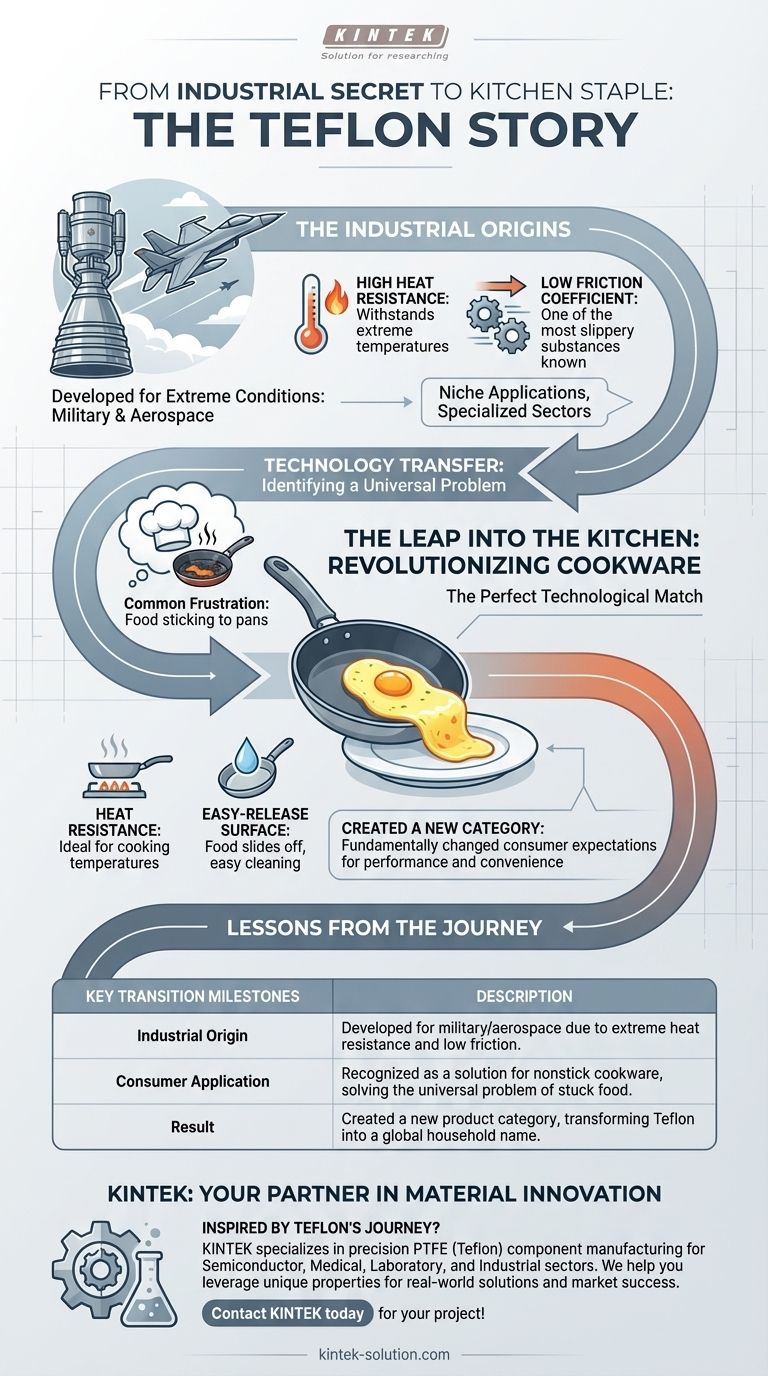

In short, Teflon transitioned from niche industrial use to a household name by finding the perfect consumer application for its unique scientific properties: nonstick cookware. Initially developed for demanding military and aerospace environments, its remarkable heat resistance and easy-release surface were recognized as an ideal solution to the common kitchen frustration of stuck food.

The journey of Teflon from a specialized industrial material to a kitchen staple is a classic example of technology transfer, where a high-performance solution developed for an extreme environment finds mass-market success by solving a simple, universal, and everyday problem.

The Industrial Origins

A Material for Extreme Conditions

Teflon's story begins in highly specialized sectors like the military and aerospace. In these fields, materials are pushed to their absolute limits.

Engineers required components that could withstand extreme temperatures and resist chemical corrosion, and Teflon's unique molecular structure made it the perfect candidate for these demanding jobs.

The Defining Properties

Two characteristics made Teflon exceptionally valuable. First was its high heat resistance, allowing it to maintain its integrity in applications where other materials would fail.

Second was its incredibly low coefficient of friction, making it one of the most slippery substances known. This "nonstick" quality was a critical feature for its initial industrial and military applications.

The Leap into the Kitchen

Identifying a Universal Problem

The genius of Teflon's consumer transition was in recognizing that its high-tech properties could solve a low-tech but universal frustration: food sticking to pans.

Every home cook understood the difficulty of cleaning burnt or stuck-on food, a problem that had existed for centuries.

The Perfect Technological Match

The same properties that made Teflon ideal for aerospace made it revolutionary for kitchenware. Its heat resistance was perfect for the high temperatures of a stovetop.

More importantly, its famous easy-release surface meant that food would slide right off, transforming the experience of both cooking and cleaning. This created a powerful and easily understood benefit for the average consumer.

Revolutionizing an Entire Industry

The introduction of Teflon-coated nonstick cookware didn't just create a new product; it created an entirely new category. It fundamentally changed consumer expectations for kitchen performance and convenience.

This single, powerful application is what propelled the Teflon brand from an obscure industrial chemical into a household name recognized globally.

Lessons from Teflon's Journey

The strategic move from a specialized to a consumer market provides a clear blueprint for innovation.

- For material science innovators: The key is to identify a common, everyday frustration that your material's unique properties can solve in a demonstrably superior way.

- For product developers: The next breakthrough consumer product may already exist as a mature technology within a specialized industrial or scientific field.

This transition serves as the definitive model for how a niche technology can achieve mass adoption by solving a problem everyone understands.

Summary Table:

| Key Transition Milestones | Description |

|---|---|

| Industrial Origin | Developed for military/aerospace due to extreme heat resistance and low friction. |

| Consumer Application | Recognized as a solution for nonstick cookware, solving the universal problem of stuck food. |

| Result | Created a new product category, transforming Teflon into a global household name. |

Inspired by Teflon's journey? Let KINTEK help you transition your specialized material into a market-leading product.

At KINTEK, we specialize in precision PTFE (Teflon) component manufacturing for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your innovative materials meet the highest standards of performance and reliability.

Whether you're developing a new application or optimizing an existing one, our team can help you leverage the unique properties of PTFE to solve real-world problems and capture new markets.

Contact KINTEK today to discuss your project and discover how our precision PTFE solutions can drive your success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE used in the beauty industry? Enhance Product Performance and Safety

- How does PTFE perform in terms of chemical resistance? The Ultimate Guide to Inert Sealing & Lining

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are the benefits of PTFE's chemical resistance? Achieve Unmatched Reliability in Corrosive Environments

- Why is PTFE chemically resistant and what applications benefit from this? Discover the Ultimate Material for Harsh Environments

- What are the future trends in PTFE molding technology? Unlock Advanced Performance with 3D Printing & Nanocomposites

- What are some key facts about Teflon/PTFE? The Ultimate Guide to Its Unique Properties and Applications

- What makes PTFE chemically resistant and why is this advantageous? Achieve Unmatched Reliability in Harsh Environments