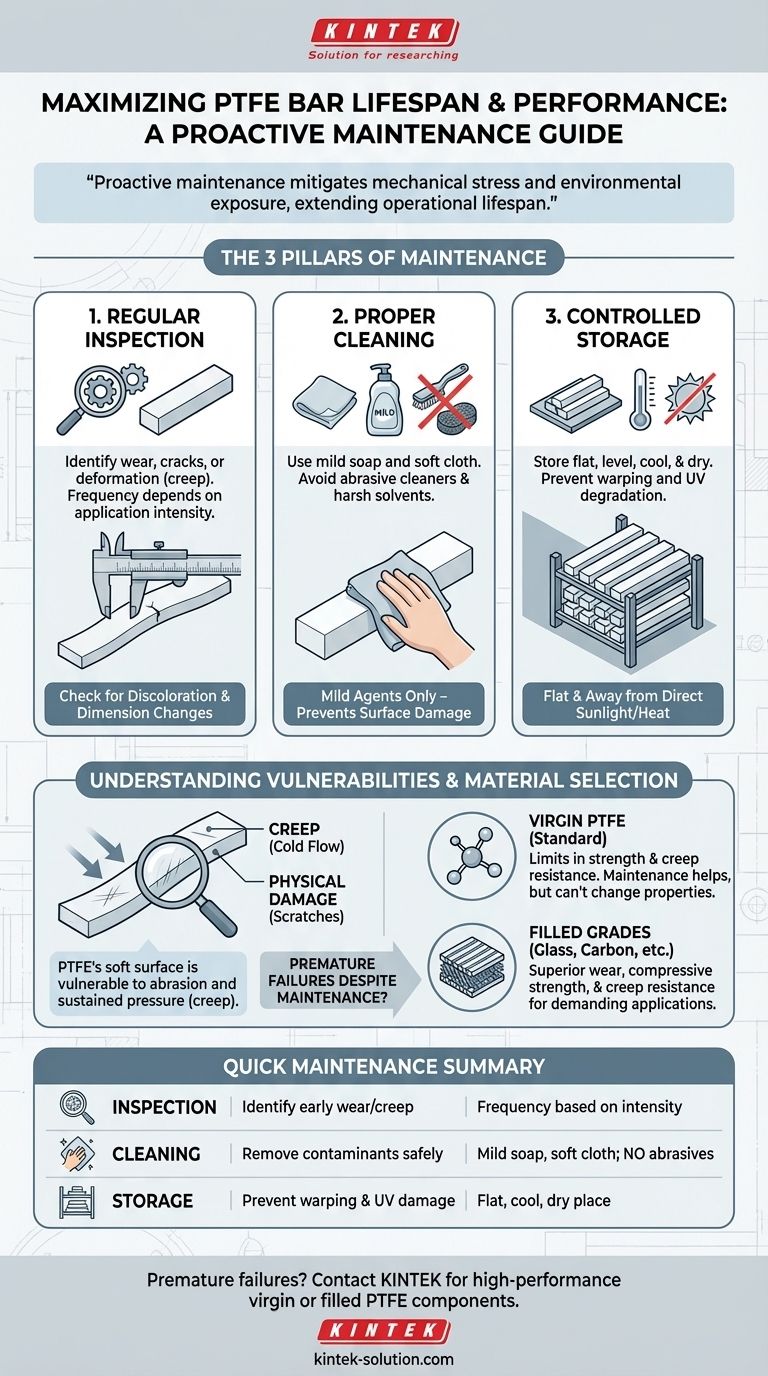

To properly maintain PTFE bars, you must implement a system of regular inspection for wear, follow specific cleaning protocols using non-abrasive materials, and ensure they are stored correctly to prevent deformation and environmental degradation. These three actions are the cornerstone of extending the material's operational lifespan and preserving its performance characteristics.

While Polytetrafluoroethylene (PTFE) is renowned for its durability and low-friction surface, its longevity is not guaranteed. Proactive maintenance is a strategic practice that mitigates the impacts of mechanical stress and environmental exposure, ensuring you realize the full potential of your investment.

The Foundations of PTFE Longevity

PTFE is often considered a "low-maintenance" material due to its extreme chemical inertness and non-stick properties. However, it is not indestructible and has specific vulnerabilities that a proper maintenance routine must address.

Understanding Material Vulnerabilities

The primary threats to a PTFE bar's integrity are physical, not chemical. Its relatively soft surface can be scratched or abraded by harsh contact.

More importantly, PTFE is susceptible to "creep" or "cold flow," a phenomenon where the material slowly deforms under sustained pressure, even at room temperature. High temperatures can accelerate this process and also cause significant thermal expansion.

Why Maintenance Matters

A consistent maintenance plan directly counteracts these vulnerabilities. It catches early signs of wear before they lead to component failure and prevents storage-related damage like warping or UV degradation, which can compromise the material before it is ever put into service.

A Practical Guide to PTFE Bar Maintenance

Implementing a simple, three-part maintenance schedule is the most effective way to protect your PTFE components.

Step 1: Regular Inspection

The goal of inspection is to identify surface or structural changes. Look for discoloration, deep scratches, cracks, or any deviation from its original dimensions, which could indicate creep. The frequency of inspection should be based on the intensity of the application.

Step 2: Proper Cleaning Protocols

Clean PTFE using a soft cloth and a mild soap or detergent solution. Rinse thoroughly with clean water afterward to remove any residue.

Crucially, avoid abrasive cleaners, scouring pads, or harsh solvents. While PTFE is chemically resistant, these can physically damage the surface, increasing its friction coefficient and creating sites for contaminants to adhere.

Step 3: Controlled Storage Conditions

Proper storage is essential. Always store PTFE bars flat on a level surface to prevent bending or warping over time.

Keep them in a cool, dry area away from direct sunlight, as prolonged UV exposure can degrade the material. Finally, protect the bars from physical impact or contact with sharp objects that could gouge the surface.

Understanding the Trade-offs: Maintenance vs. Material Selection

Sometimes, maintenance alone cannot solve performance issues if the material itself is not suited for the application.

The Limits of Unfilled PTFE

The advice above applies primarily to standard, or "virgin," PTFE. While versatile, it has inherent limitations in mechanical strength and resistance to creep and wear. No amount of maintenance can change these fundamental properties.

Enhancing Performance with Fillers

For more demanding applications, filled grades of PTFE offer superior performance. Manufacturers incorporate fillers like glass, carbon, or metals (such as stainless steel) to enhance specific characteristics.

For example, glass-filled PTFE has better wear resistance, while carbon-filled PTFE offers improved compressive strength and resistance to creep. This is the same principle used to create metal-inserted gaskets that resist blowout.

When Maintenance Isn't Enough

If you experience premature component failure despite proper maintenance, the root cause may be material selection. High loads, abrasive conditions, or the need for tight dimensional tolerance under pressure often require a filled grade of PTFE.

Making the Right Choice for Your Application

Use your operational goals to guide your approach to PTFE management.

- If your primary focus is preserving existing virgin PTFE components: Implement a strict schedule of inspection, cleaning with mild agents, and storing the bars flat away from UV light and heat sources.

- If your primary focus is maximizing performance in a new, demanding project: Consider starting with a filled grade of PTFE (e.g., glass or carbon-filled) to gain superior wear and creep resistance from the outset.

- If you are experiencing premature failures: The problem is likely a mismatch between the material and the application's stress. Re-evaluate the operational loads and temperatures to determine if a more robust, filled PTFE is necessary.

By aligning your maintenance strategy with the correct material choice, you ensure your PTFE components function as reliable, long-term assets.

Summary Table:

| Maintenance Action | Key Purpose | Critical Detail |

|---|---|---|

| Regular Inspection | Identify early wear, cracks, or deformation (creep) | Frequency depends on application intensity |

| Proper Cleaning | Remove contaminants without damaging the surface | Use mild soap, soft cloth; avoid abrasives and harsh solvents |

| Correct Storage | Prevent warping and UV degradation | Store flat, in a cool, dry place away from sunlight |

Are your PTFE components failing prematurely? Proper maintenance is key, but sometimes the solution requires a more robust material from the start. KINTEK specializes in manufacturing high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, and industrial sectors. Whether you need durable virgin PTFE or advanced filled grades (like glass or carbon) for superior wear and creep resistance, we deliver precision from prototypes to high-volume orders. Contact KINTEK today to discuss your application and ensure long-lasting performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications