To increase the pressure rating of a high-speed, low-pressure PTFE seal, its profile must be modified to increase rigidity and resist deformation. The two primary methods are reinforcing the seal with an external metal band for moderate pressure increases, or redesigning the seal with an extended heel for high-pressure applications.

The core challenge with pressure is preventing the seal material from being forced, or "extruded," into the clearance gap between components. Therefore, any modification for higher pressure must focus on increasing the seal's structural stability to resist this force.

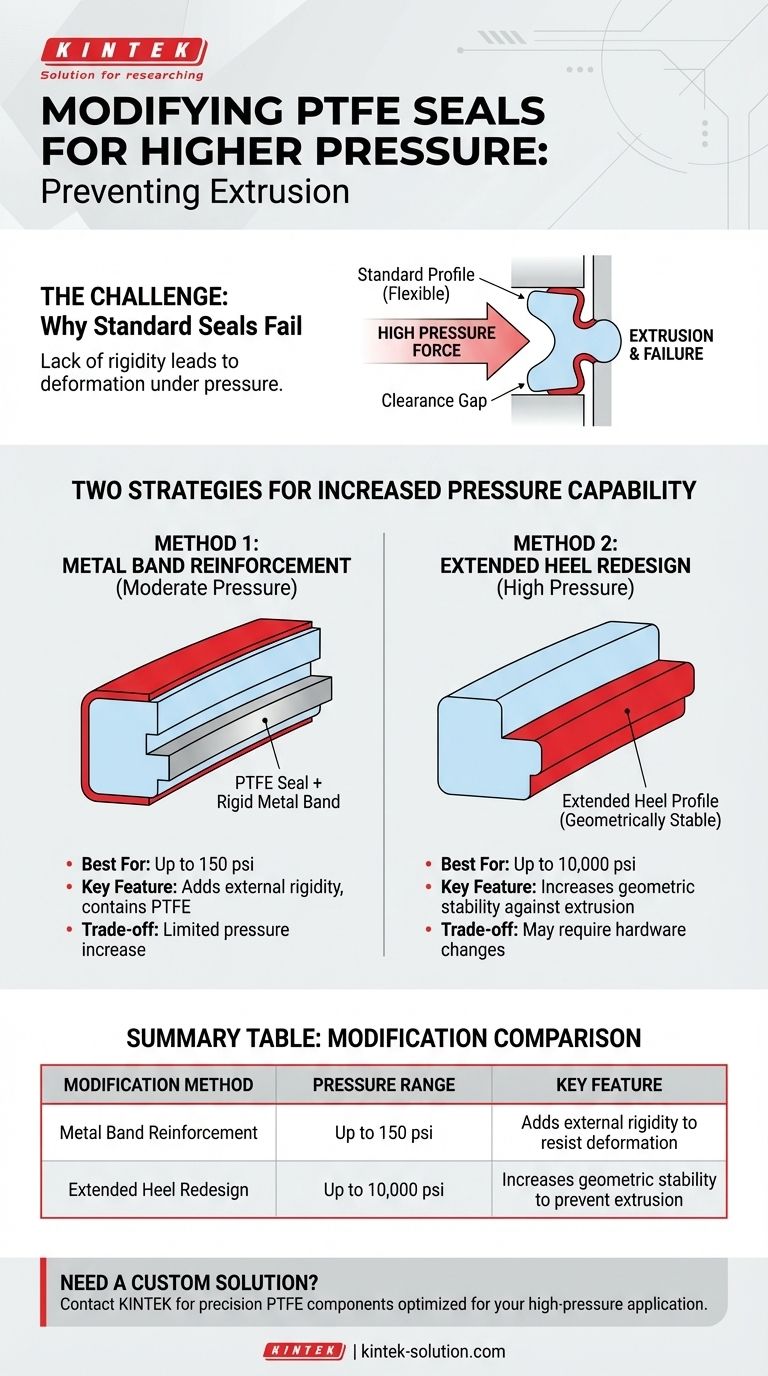

The Challenge: Why Standard Seals Fail Under Pressure

A seal's ability to handle pressure is fundamentally a question of its material properties and geometric stability. A profile designed for high speed and low pressure is optimized for flexibility and low friction, not rigidity.

The Principle of Extrusion

Under high pressure, the force exerted by the system fluid pushes against the seal face. If this force is great enough, it will deform the relatively soft PTFE material and force it into the small gap between the rotating shaft and the stationary housing, causing rapid wear and catastrophic failure.

Limits of the Low-Pressure Profile

The standard high-speed profile lacks the structural mass and rigidity to resist significant deformation. Its design prioritizes maintaining contact with the shaft at high rotational speeds, which is a different engineering challenge than withstanding high static or dynamic pressure.

Two Core Strategies for Increasing Pressure Capability

To counter extrusion and failure, the seal's design must be reinforced. This is typically achieved through one of two distinct methods, each suited for different pressure levels.

Method 1: Reinforcement with a Metal Band

For a moderate increase in pressure handling, a metal band can be added to the outer diameter of the PTFE seal jacket.

This band acts as a rigid support structure, physically containing the PTFE material. It directly counteracts the pressure that would otherwise cause the seal to deform, increasing its overall rigidity.

This modification is effective for raising pressure ratings up to approximately 150 psi.

Method 2: Redesigning with an Extended Heel

For a significant increase in pressure capability, the geometry of the seal itself must be changed by extending its heel.

The "heel" is the static, non-contact portion of the seal that sits in the gland. Extending its axial length makes the entire seal profile more robust and stable, providing much greater inherent resistance to being pushed and deformed by pressure.

This design approach, often used in conjunction with an O-ring energizer, allows the seal to withstand pressures up to 10,000 psi.

Understanding the Trade-offs

Choosing a modification strategy requires balancing performance needs with design constraints. The two methods are not interchangeable and solve for different scales of the pressure problem.

Metal Band: The Moderate Upgrade

A metal-banded seal is an effective upgrade for systems where pressure slightly exceeds the limits of a standard profile. It's a direct reinforcement of an existing design concept.

However, its pressure-handling ability is limited. It provides a good incremental improvement but is not a solution for truly high-pressure environments.

Extended Heel: The High-Pressure Solution

The extended heel design is the definitive solution for high-pressure rotary sealing. Its geometric stability is fundamentally superior for resisting extrusion.

This is a different seal profile, not just a simple addition. Implementing it may require designing the hardware (the seal gland or housing) specifically to accommodate its larger, more robust shape.

Making the Right Choice for Your Application

Your decision must be driven by the specific pressure requirements of your equipment.

- If your primary focus is a moderate pressure increase (up to 150 psi): Reinforcing the seal with a metal band is the most direct and effective modification.

- If your primary focus is high-pressure capability (up to 10,000 psi): You must select a seal profile specifically designed with an extended heel for the necessary rigidity and stability.

Ultimately, matching the seal's geometric design to the system's operating pressure is critical for ensuring long-term reliability.

Summary Table:

| Modification Method | Best For Pressure Range | Key Feature |

|---|---|---|

| Metal Band Reinforcement | Up to 150 psi | Adds external rigidity to resist deformation |

| Extended Heel Redesign | Up to 10,000 psi | Increases geometric stability to prevent extrusion |

Need a custom PTFE seal solution for your high-pressure application?

At KINTEK, we specialize in designing and manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our expertise in custom fabrication ensures your seals are optimized for performance, pressure, and reliability.

Contact us today to discuss your specific requirements and let our engineers provide a solution that enhances your system's durability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F