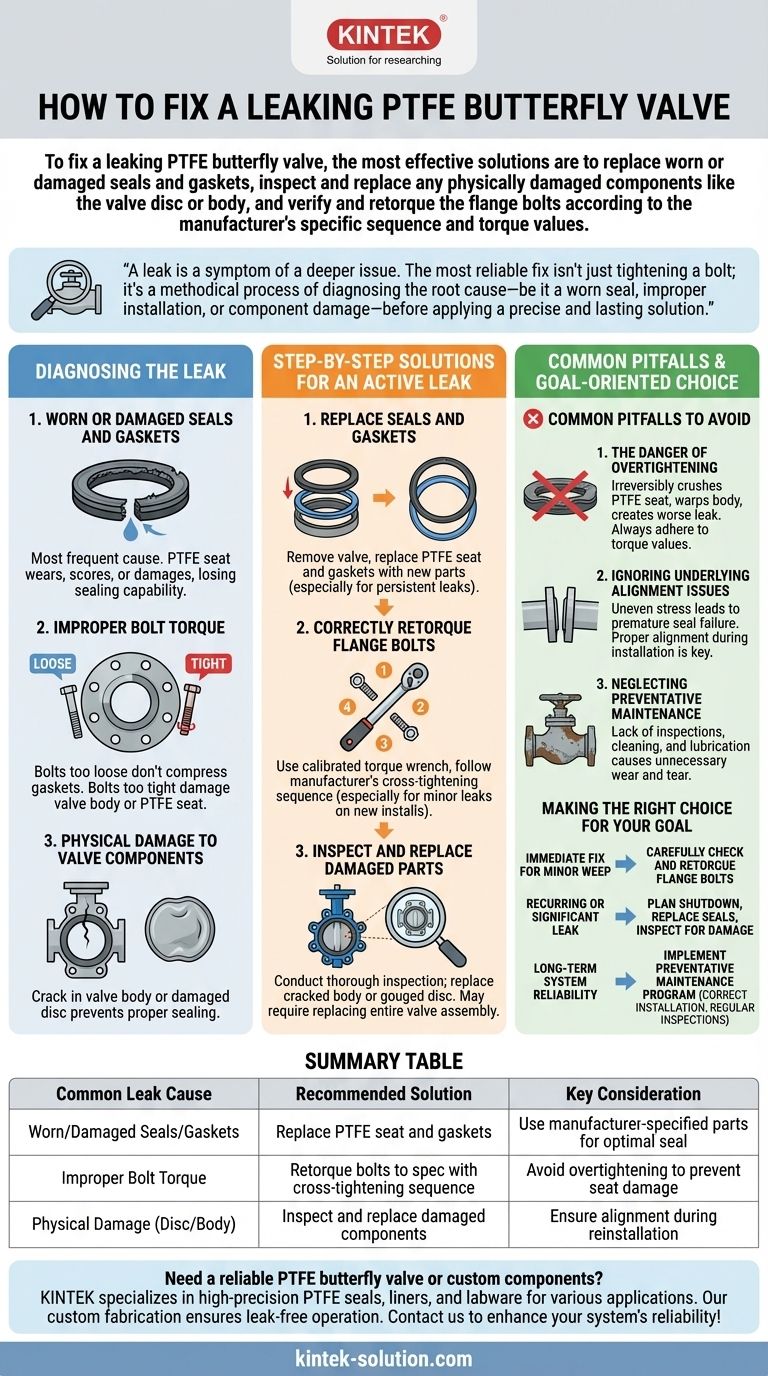

To fix a leaking PTFE butterfly valve, the most effective solutions are to replace worn or damaged seals and gaskets, inspect and replace any physically damaged components like the valve disc or body, and verify and retorque the flange bolts according to the manufacturer's specific sequence and torque values. These actions address the most common failure points that lead to leaks.

A leak is a symptom of a deeper issue. The most reliable fix isn't just tightening a bolt; it's a methodical process of diagnosing the root cause—be it a worn seal, improper installation, or component damage—before applying a precise and lasting solution.

Diagnosing the Source of the Leak

Before you can implement a permanent fix, you must accurately identify why the valve is failing. A leak is almost always traced back to one of three primary causes.

Worn or Damaged Seals and Gaskets

This is the most frequent cause of leaks. The PTFE (Teflon) seat is designed to create a tight seal, but over time it can wear down, become scored by abrasive media, or get damaged by improper operation, leading to a loss of sealing capability.

Improper Bolt Torque

The bolts that hold the valve between two pipe flanges must be tightened to a precise specification. If the bolts are too loose, they won't create enough compressive force on the gaskets. If they are too tight, they can damage the valve body or crush the PTFE seat, creating a leak path.

Physical Damage to Valve Components

Though less common, direct damage can cause significant leaks. A crack in the valve body from over-pressurization or physical impact, or a damaged disc that no longer seats properly, will prevent the valve from ever achieving a proper seal.

Step-by-Step Solutions for an Active Leak

Once you have a probable diagnosis, you can apply the appropriate solution. Always follow proper safety procedures, such as depressurizing and isolating the line, before performing any maintenance.

Replace Seals and Gaskets

If the valve has been in service for a long time or if the leak is persistent, the internal seals are the most likely culprit. The only reliable solution is to remove the valve from the line and replace the PTFE seat and any associated gaskets with new parts.

Correctly Retorque Flange Bolts

For minor leaks, especially on newer installations, improper torque may be the cause. Using a calibrated torque wrench, check and tighten the bolts to the manufacturer's recommended value. It is critical to follow the specified cross-tightening sequence (like tightening lug nuts on a car) to ensure even pressure.

Inspect and Replace Damaged Parts

During any repair, conduct a thorough visual inspection of the valve's core components. If you find any cracks on the valve body or deep gouges on the disc's sealing edge, the damaged component must be replaced. In many cases, this will require replacing the entire valve assembly.

Common Pitfalls to Avoid

Fixing a valve leak correctly involves avoiding common mistakes that can either fail to solve the problem or make it worse.

The Danger of Overtightening

The most common reactive mistake is to simply "crank down" on the flange bolts. Overtightening can irreversibly crush the PTFE seat, warp the valve body, and create a more severe leak than the one you started with. Always adhere to the specified torque values.

Ignoring Underlying Alignment Issues

A valve that is not perfectly aligned with the pipe flanges will experience uneven stress. This will inevitably lead to premature seal failure and chronic leaks. Proper alignment during installation is the foundation of a leak-free service life.

Neglecting Preventative Maintenance

Valves are not "set-it-and-forget-it" components. A lack of regular inspections, cleaning to remove process buildup, and lubrication of moving parts (where applicable) can lead to operational issues that cause unnecessary wear and tear on sealing surfaces.

Making the Right Choice for Your Goal

Your approach should be dictated by the severity of the leak and your operational goals.

- If your primary focus is an immediate fix for a minor weep: Carefully check and retorque the flange bolts to the manufacturer's specifications using the correct tightening pattern.

- If your primary focus is a recurring or significant leak: Plan a shutdown to remove the valve, replace the PTFE seat and flange gaskets, and inspect the disc and body for damage.

- If your primary focus is long-term system reliability: Implement a preventative maintenance program that prioritizes correct installation procedures and schedules regular valve inspections.

By shifting from reactive repairs to a proactive maintenance strategy, you ensure the integrity and reliability of your entire system.

Summary Table:

| Common Leak Cause | Recommended Solution | Key Consideration |

|---|---|---|

| Worn/Damaged Seals/Gaskets | Replace PTFE seat and gaskets | Use manufacturer-specified parts for optimal seal |

| Improper Bolt Torque | Retorque bolts to spec with cross-tightening sequence | Avoid overtightening to prevent seat damage |

| Physical Damage (Disc/Body) | Inspect and replace damaged components | Ensure alignment during reinstallation |

Need a reliable PTFE butterfly valve or custom components? KINTEK specializes in manufacturing high-precision PTFE seals, liners, and labware for semiconductor, medical, laboratory, and industrial applications. Our custom fabrication services—from prototypes to high-volume orders—ensure your valves operate leak-free. Contact us today to discuss your specific requirements and enhance your system's reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How are PTFE tubes manufactured and what are their uses? A Guide to High-Performance Tubing Solutions

- What are some common applications of PTFE balls? Essential Uses in Chemical & Low-Friction Systems

- Why are PTFE gaskets considered a preferred sealing solution? Ensure Reliability in Demanding Environments

- Can PTFE envelope gaskets be customized? Tailor the Perfect Seal for Your Application

- What machining technique is ideal for making round or conical shapes in PTFE? Use Turning for Precision

- What makes Teflon bushings suitable for harsh environments? Unmatched Chemical & Thermal Resistance

- What materials are used for jacket profiles and springs in PTFE seals? A Guide to Material Selection

- What is the temperature range for expanded PTFE? From -400°F to 500°F for Extreme Environments