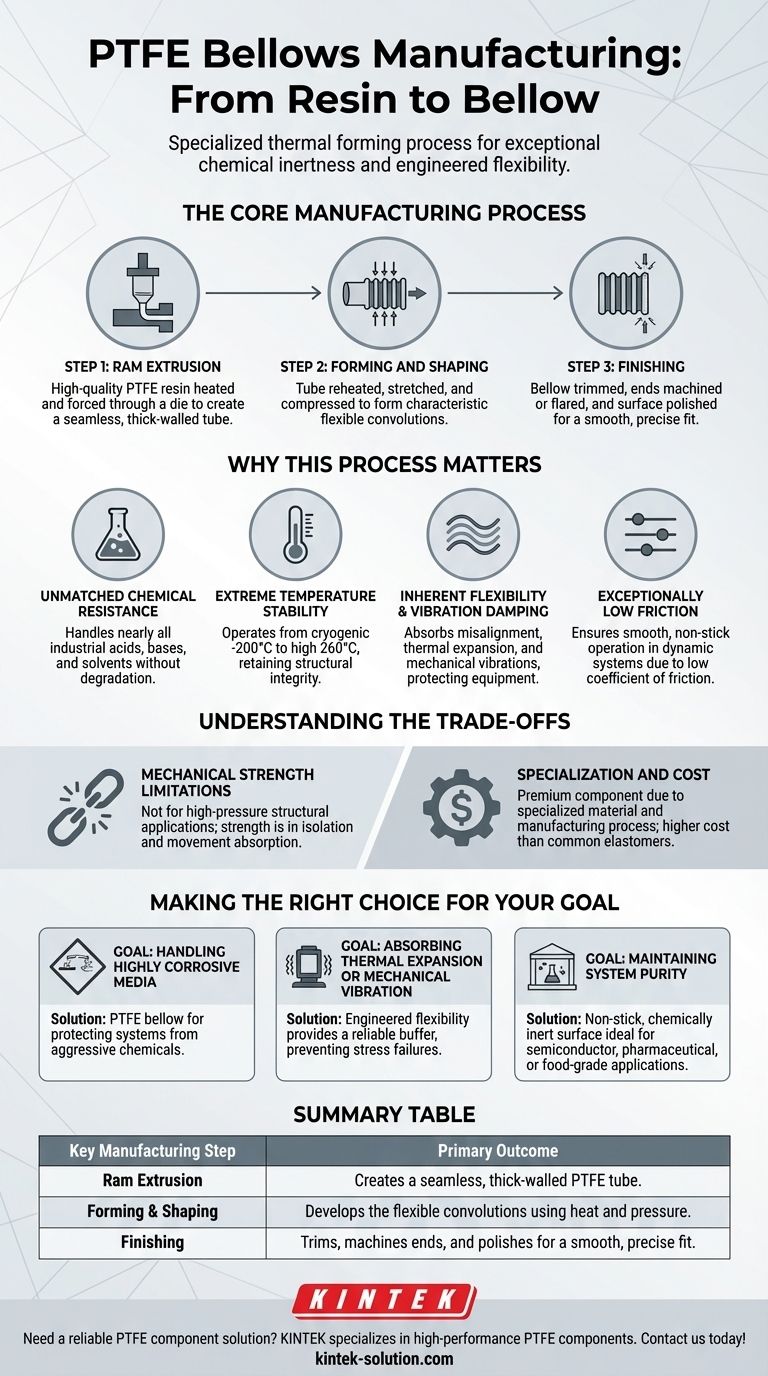

At its core, the manufacturing of Polytetrafluoroethylene (PTFE) bellows is a specialized thermal forming process. It begins with ram extrusion, where raw PTFE resin is heated and forced through a die to create a seamless tube, which is then mechanically shaped into its final, flexible form.

The key takeaway is that the manufacturing process doesn't just create a shape; it preserves and leverages PTFE's unique molecular properties, resulting in a component that combines exceptional chemical inertness with engineered mechanical flexibility.

The Core Manufacturing Process: From Resin to Bellow

The journey from raw polymer to a finished bellow involves a few precise steps. Each stage is critical for ensuring the final component meets demanding performance standards.

Step 1: Ram Extrusion

The process begins with high-quality PTFE resin. This powder is fed into a ram extruder, which heats the material and uses a hydraulic ram to press it through a die, forming a continuous, thick-walled tube. This initial extrusion is what creates the seamless foundation of the bellow.

Step 2: Forming and Shaping

The extruded tube is then reheated to a specific temperature. Using specialized dies and controlled pressure, the tube is stretched and compressed along its length. This action forms the characteristic convolutions, or folds, that give the bellow its flexibility.

Step 3: Finishing

Once the convoluted shape is set, the bellow is carefully trimmed to the required length. The ends may be machined or flared to create specific connection points. A final polishing step ensures a smooth surface, minimizing friction and potential contamination points.

Why This Process Matters: The Resulting Properties

Understanding the manufacturing method is key to understanding why PTFE bellows are chosen for critical applications. The process is designed to lock in the material's inherent advantages.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers known. The extrusion and forming process maintains this property, producing a bellow that can safely handle nearly all industrial acids, bases, and solvents without degradation.

Extreme Temperature Stability

The material itself allows for an incredibly wide operating temperature range, from cryogenic lows of -200°C (-328°F) up to high temperatures of 260°C (500°F). The manufacturing process ensures the bellow retains its structural integrity across this spectrum.

Inherent Flexibility and Vibration Damping

The convoluted shape created during the forming stage is the source of the bellow's primary function. This geometry allows it to absorb pipeline misalignment, thermal expansion, and mechanical vibrations, protecting sensitive equipment from stress.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property, preserved through manufacturing, ensures smooth, non-stick operation in dynamic systems.

Understanding the Trade-offs

While highly effective, PTFE bellows are not a universal solution. Their unique properties come with specific considerations that are crucial for proper application.

Mechanical Strength Limitations

PTFE is a relatively soft material. While excellent for flexibility and chemical resistance, these bellows are not intended for high-pressure structural applications where a metal bellow would be required. Their strength lies in isolation and movement absorption, not pressure containment.

Specialization and Cost

As a high-performance fluoropolymer, PTFE is more costly than common elastomers like rubber. The specialized manufacturing process further positions these bellows as a premium component, best used where their unique chemical and thermal properties are a necessity.

Making the Right Choice for Your Goal

Selecting the right component depends entirely on the primary challenge you need to solve.

- If your primary focus is handling highly corrosive media: The inert nature of a PTFE bellow makes it the definitive choice for protecting systems from aggressive chemicals.

- If your primary focus is absorbing thermal expansion or mechanical vibration: The engineered flexibility of the bellow provides a reliable buffer between components, preventing stress-induced failures.

- If your primary focus is maintaining system purity: The non-stick, chemically inert surface of PTFE prevents contamination, making it ideal for semiconductor, pharmaceutical, or food-grade applications.

Ultimately, a PTFE bellow is an engineered solution for environments where other materials would quickly fail.

Summary Table:

| Key Manufacturing Step | Primary Outcome |

|---|---|

| Ram Extrusion | Creates a seamless, thick-walled PTFE tube. |

| Forming & Shaping | Develops the flexible convolutions using heat and pressure. |

| Finishing | Trims, machines ends, and polishes for a smooth, precise fit. |

Need a reliable PTFE component solution?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom bellows, seals, liners, and labware. Our precision production process ensures you get components with superior chemical inertness, temperature stability, and flexibility—exactly as described in this article.

We serve the semiconductor, medical, laboratory, and industrial sectors, offering custom fabrication from prototypes to high-volume orders.

Contact us today to discuss your specific requirements and get a quote!

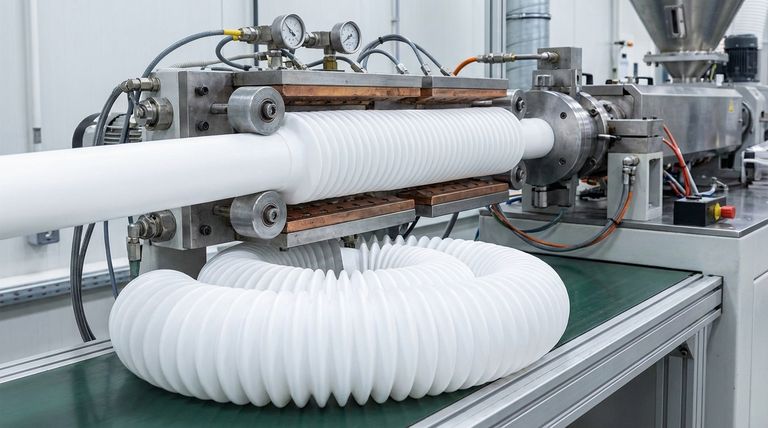

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE over rubber in rotary shaft seals? Superior Performance in Extreme Conditions

- What are the key properties of PTFE flange gaskets? Unmatched Chemical & Thermal Resistance

- How do PTFE and NBR oil seals compare in terms of flexibility and installation? Choose the Right Seal for Your Application

- What are the advantages of a PTFE rotary lip seal not being spring-energized? Achieve Superior High-Speed Performance

- What are some physical properties of PTFE with fillers? Enhance Strength, Wear, and Thermal Performance

- How does PTFE contribute to the performance of metal expansion joints? Enhance Durability in Harsh Chemical Environments

- What are the common characteristics of PTFE and Graphite packing materials? Key Similarities and Critical Differences

- What are the advantages of Teflon sheets? Superior Performance in Harsh Environments