In the automotive industry, expanded Polytetrafluoroethylene (ePTFE) sheets are primarily utilized to create high-performance gaskets, seals, washers, and protective sleeves for cable assemblies. These components are specified for critical systems where they must endure extreme heat, aggressive chemicals, and constant vibration, ensuring the long-term reliability of engines, fuel systems, and electronics.

The core reason for using ePTFE in vehicles is not just its material properties, but its function as an engineering solution. It is chosen to solve the fundamental challenge of maintaining integrity and preventing failure in the harsh, dynamic environment of a modern automobile.

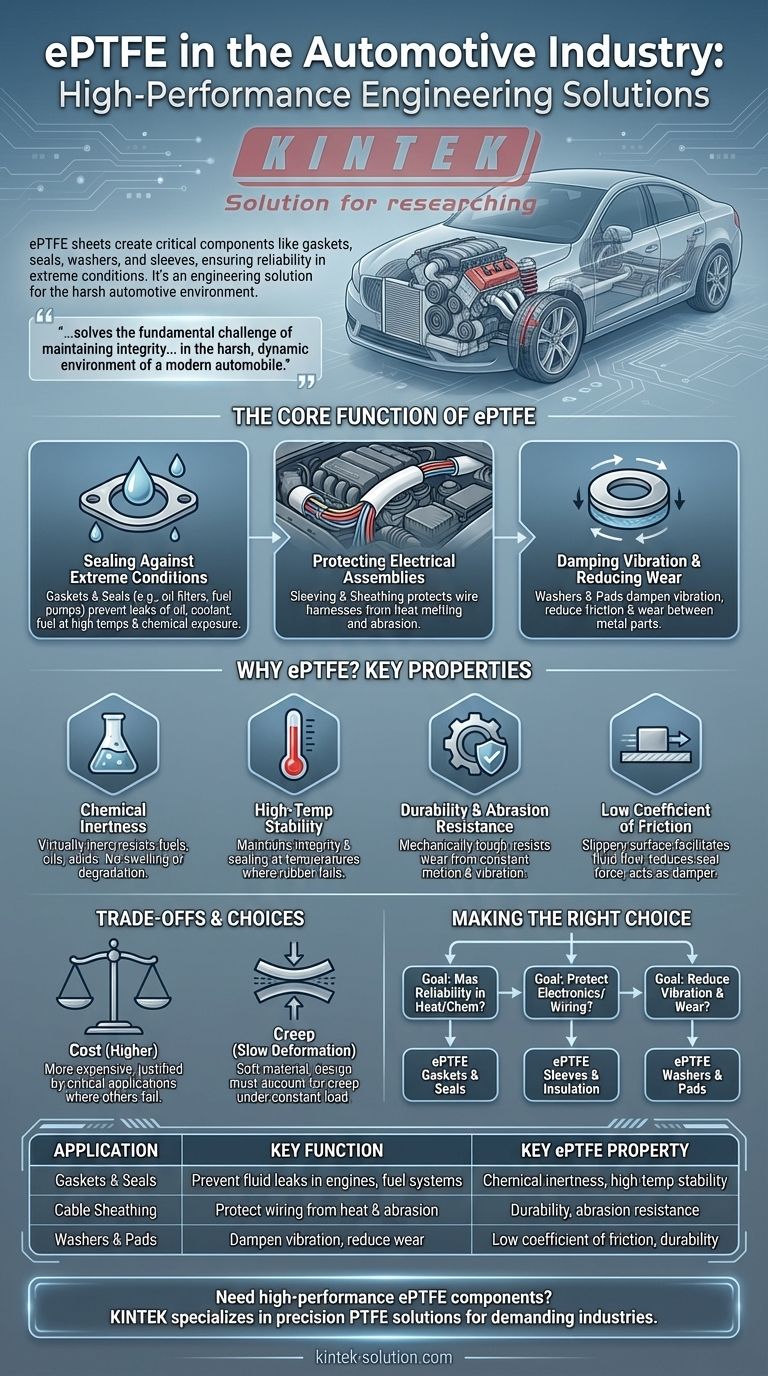

The Core Function of ePTFE in Automotive Systems

Designers turn to ePTFE not simply as a material, but as a problem-solver for the most demanding applications within a vehicle's architecture. Its unique structure provides a reliable barrier in environments where lesser materials would quickly degrade.

Sealing Against Extreme Conditions

In systems like the engine, transmission, and fuel lines, maintaining a perfect seal is non-negotiable. ePTFE sheets are formed into gaskets and seals that are placed between mating surfaces.

These components are essential in applications like oil filters and fuel pumps. They prevent leaks of critical fluids—such as engine oil, coolant, and gasoline—even when exposed to high temperatures from combustion and the corrosive nature of the fluids themselves.

Protecting Electrical and Cable Assemblies

Modern vehicles contain kilometers of wiring. ePTFE is used as a protective sheathing or sleeve for wire harnesses and cable assemblies, particularly those routed through the engine bay.

Its high-temperature resistance prevents the insulation from melting, while its durability protects sensitive wires from abrasion caused by engine vibration and contact with other components.

Damping Vibration and Reducing Wear

Beyond sealing, ePTFE sheets are fabricated into washers and pads that serve a mechanical function. When placed between metal components, they act as a cushion to dampen vibrations.

This not only reduces noise but also minimizes friction and wear between parts, extending the operational lifespan of the entire assembly.

Why ePTFE? A Breakdown of Key Properties

The utility of ePTFE in these applications stems directly from a combination of powerful material properties. Understanding these attributes reveals why it is often the only viable choice for engineers.

Exceptional Chemical Inertness

ePTFE is virtually inert and does not react with the vast majority of chemicals. In an automotive context, this means it will not swell, soften, or degrade when exposed to fuels, oils, transmission fluid, or battery acid, guaranteeing a stable and long-lasting seal.

High-Temperature Stability

Components near the engine and exhaust systems must endure significant heat. ePTFE maintains its structural integrity and sealing capability at temperatures that would cause conventional elastomers like rubber to fail.

Durability and Abrasion Resistance

The material is mechanically tough and resists wear from friction and vibration. This makes it ideal for dynamic applications where components are in constant motion or under pressure, ensuring it does not thin out or tear over time.

Low Coefficient of Friction

Known for its slippery, non-stick surface, ePTFE facilitates the smooth flow of fluids in piping systems and reduces the force needed to maintain a seal. This property is also what allows it to function effectively as a vibration damper, letting components move slightly against each other without causing wear.

Understanding the Trade-offs

While ePTFE is a superior material for many applications, its selection involves considering certain practical limitations. Acknowledging these trade-offs is key to making an informed engineering decision.

Cost Considerations

ePTFE is a high-performance polymer, and its manufacturing process makes it significantly more expensive than commodity materials like silicone or nitrile rubber. Its use is therefore justified primarily in applications where performance and reliability are paramount and other materials would fail.

Mechanical Limitations

While durable, ePTFE is a soft material that can be susceptible to "creep," or slow deformation under a constant load. Joint and gasket design must account for this property to ensure a long-term, stable seal is maintained without over-compressing the material.

Making the Right Choice for Your Goal

To apply this knowledge effectively, align your material choice with the primary challenge you are trying to solve.

- If your primary focus is maximum reliability in high-heat, chemically aggressive environments: ePTFE gaskets and seals are the definitive choice for sealing engine blocks, transmissions, and fuel systems.

- If your primary focus is protecting sensitive electronics and wiring: ePTFE sleeves and cable assembly insulation provide essential protection from heat and abrasion in the engine bay.

- If your primary focus is reducing vibration and wear between critical components: ePTFE washers and pads offer an effective solution that also resists environmental degradation.

By leveraging the unique properties of ePTFE, you can engineer solutions that ensure durability and performance for the lifetime of the vehicle.

Summary Table:

| Application | Key Function | Key ePTFE Property Utilized |

|---|---|---|

| Gaskets & Seals | Prevent fluid leaks in engines, fuel systems | Chemical inertness, high-temperature stability |

| Cable Sheathing | Protect wiring from heat and abrasion | Durability, abrasion resistance |

| Washers & Pads | Dampen vibration, reduce wear | Low coefficient of friction, durability |

Need high-performance ePTFE components for your automotive application?

KINTEK specializes in the precision manufacturing of PTFE components, including custom ePTFE seals, gaskets, liners, and labware. We serve the semiconductor, medical, laboratory, industrial, and specialized automotive industries. Our expertise ensures your components meet the demanding requirements for heat, chemical resistance, and durability.

Whether you need prototypes or high-volume production, we deliver solutions that enhance reliability and longevity. Contact KINTEK today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is the non-reactivity of PTFE fasteners important in medical devices? Ensuring Patient Safety and Device Integrity

- What are the limitations of using PTFE in sealing applications? Overcome Mechanical Weaknesses for Reliable Sealing

- What are the common applications of Teflon bushings in industrial machinery? Solve Friction, Corrosion, and Contamination Problems

- Where are thick PTFE washers (2mm – 4mm) typically used? For High-Pressure Sealing & Electrical Insulation

- Why are PTFE lined check valves ideal for commercial environments? Ensure System Integrity in Corrosive Applications

- What happens when clearance develops in a PTFE-lined bearing? A Guide to Catastrophic Failure

- What are some filler materials used with PTFE to enhance its properties? A Guide to Reinforced PTFE

- What are the limitations of Teflon encapsulated O-rings in terms of chemical resistance? Key Weaknesses to Avoid Seal Failure