Yes, PTFE parts are exceptionally customizable. Polytetrafluoroethylene (PTFE) is a highly versatile fluoropolymer that can be precisely fabricated to meet a wide range of specific requirements through processes like CNC machining. This adaptability allows for tailored solutions across industries, from custom lab equipment like bottles to highly specific medical-grade liners.

While PTFE offers extensive customization possibilities, success hinges on designing for the material's unique properties. Factors like high thermal expansion and inherent softness must be accounted for to ensure the final part performs as intended in its operational environment.

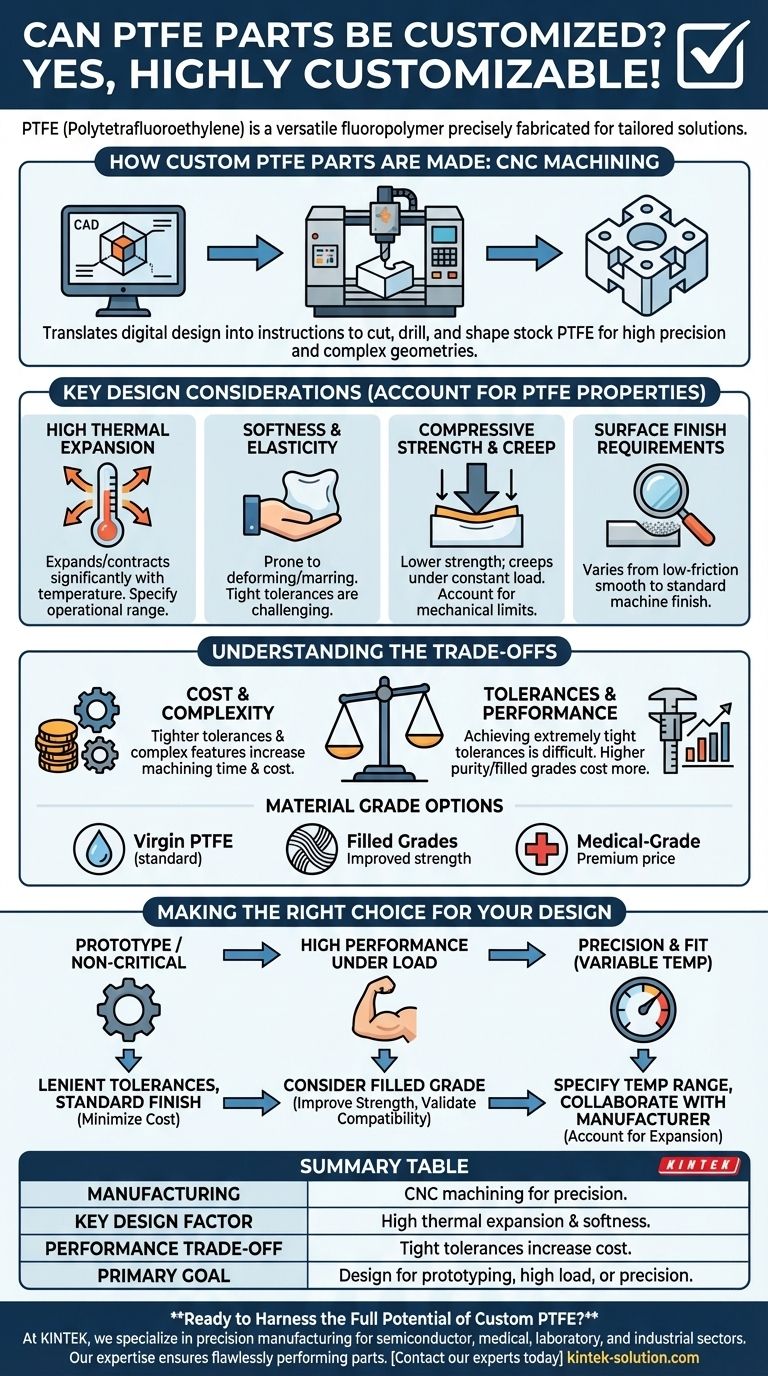

How Custom PTFE Parts are Made

The primary method for creating custom PTFE components is through precision manufacturing techniques that can adapt to the material's specific characteristics.

The Role of CNC Machining

CNC (Computer Numerical Control) machining is the most common and effective method for producing custom PTFE parts. An operator translates a digital design (CAD model) into instructions for a machine, which then cuts, drills, and shapes a block of stock PTFE into the final component.

This process allows for high precision and repeatability, making it possible to fabricate complex geometries that meet specific design criteria for dimensions, surface finish, and functional features.

Key Design Considerations for Customization

To successfully customize a PTFE part, your design must account for the material's distinct physical and thermal properties. Ignoring these can lead to parts that do not fit or fail under operational stress.

High Thermal Expansion

PTFE has a very high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. A part designed for room temperature may be out of tolerance in a hotter or colder environment. Your design must specify the part's intended operational temperature range.

Softness and Elasticity

PTFE is a relatively soft material, which makes it prone to deforming or marring during machining if not handled correctly. This softness also means achieving extremely tight tolerances can be more challenging than with rigid metals or plastics. Experienced machinists use specialized tools and techniques to manage this.

Compressive Strength and Creep

While PTFE has excellent chemical resistance, its compressive strength is lower than many other engineering plastics. It can also experience "creep" or "cold flow," where the material slowly deforms over time when under a constant load. Custom designs must account for these mechanical limitations to prevent failure.

Surface Finish Requirements

CNC machining can produce a variety of surface finishes on PTFE parts. Your application may require an extremely smooth surface for a low-friction seal, or a standard machine finish may be sufficient for a structural component. This is a key parameter that can be customized.

Understanding the Trade-offs of PTFE Customization

While versatile, customizing PTFE comes with certain challenges and considerations that impact cost and performance.

The Challenge of Tight Tolerances

Due to its softness and high thermal expansion, holding extremely tight tolerances (e.g., less than +/- 0.002 inches) on PTFE parts is difficult and expensive. It requires specialized expertise and a climate-controlled machining environment, which increases cost.

Cost Implications of Complexity

The more complex your design, the more machining time is required. Features like thin walls, intricate internal geometries, and very fine surface finishes will directly increase the manufacturing cost of your custom part.

Material Grade and Purity

PTFE is available in various grades, including virgin PTFE, filled grades (e.g., glass or carbon-filled for improved strength), and medical-grade. Choosing the right grade is critical, but higher-purity or specialized filled grades come at a premium price.

Making the Right Choice for Your Design

Use these guidelines to align your design with your primary goal.

- If your primary focus is a prototype or non-critical component: You can design with more lenient tolerances and a standard surface finish to minimize manufacturing costs.

- If your primary focus is high performance under load: Consider using a filled grade of PTFE to improve mechanical strength and reduce creep, but be sure to validate its chemical compatibility.

- If your primary focus is precision and fit in a variable-temperature environment: You must specify the operational temperature range and work closely with the manufacturer to account for thermal expansion in the design and machining process.

By designing for its unique properties from the start, you can harness the full potential of PTFE for your specific application.

Summary Table:

| Aspect | Customization Consideration |

|---|---|

| Manufacturing | CNC machining for precision and complex geometries. |

| Key Design Factor | High thermal expansion and material softness. |

| Performance Trade-off | Tight tolerances increase cost; filled grades improve strength. |

| Primary Goal | Design for prototyping, high load, or precision fit. |

Ready to Harness the Full Potential of Custom PTFE?

At KINTEK, we specialize in precision manufacturing of custom PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in CNC machining ensures your design accounts for PTFE's unique properties, delivering parts that perform flawlessly in your specific application—from prototypes to high-volume production.

Contact our experts today to discuss your project requirements and receive a quote tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do Teflon bellow mechanical seals contribute to environmental protection in pulp and paper mills? Prevent Hazardous Leaks

- Why are PTFE liners considered cost-effective? Maximize Uptime and Reduce Long-Term Costs

- What are the key characteristics of Polytetrafluoroethylene (PTFE) in gland packings? Maximize Sealing Performance

- What are some common applications of filled PTFE? Enhance Performance in Demanding Industries

- What are the benefits of using bronze as a filler in PTFE? Enhance Wear, Creep & Thermal Performance

- How does the structure of expanded PTFE gaskets differ from pure PTFE gaskets? Unlock Superior Sealing Performance

- What are the key properties of PTFE/Teflon? Why It's the Ideal Choice for Demanding Machined Parts

- What is the significance of valve design in preventing PTFE seat deformation? Ensure Long-Term Sealing Integrity