Yes, PTFE is frequently modified with additives. This practice is not just common; it is essential for engineering applications that require more than PTFE's natural lubricity and chemical inertness. Pure, or "virgin," PTFE is mechanically weak, and these additives are used to create high-performance compounds with enhanced strength, wear resistance, and stability.

While virgin PTFE offers exceptional chemical resistance and low friction, it suffers from poor mechanical properties. Adding fillers is a strategic trade-off, sacrificing a degree of purity to gain critical improvements in wear resistance, creep strength, and thermal conductivity for demanding applications.

The Case for Modifying Virgin PTFE

To understand why additives are used, you must first appreciate the inherent strengths and weaknesses of Polytetrafluoroethylene (PTFE) in its pure state.

The Unmatched Benefits of Virgin PTFE

Virgin PTFE is a remarkable material known for two primary characteristics: an extremely low coefficient of friction and near-universal chemical inertness. It is the ideal choice when you need a slippery, non-reactive surface.

The Critical Limitations: Cold Flow and Wear

The main drawback of virgin PTFE is its poor mechanical stability. It suffers from creep, also known as cold flow, where the material slowly deforms permanently when placed under a sustained load, even at room temperature.

Furthermore, its resistance to abrasive wear is very low. In dynamic applications like bearings or seals, pure PTFE will wear away quickly, leading to premature failure.

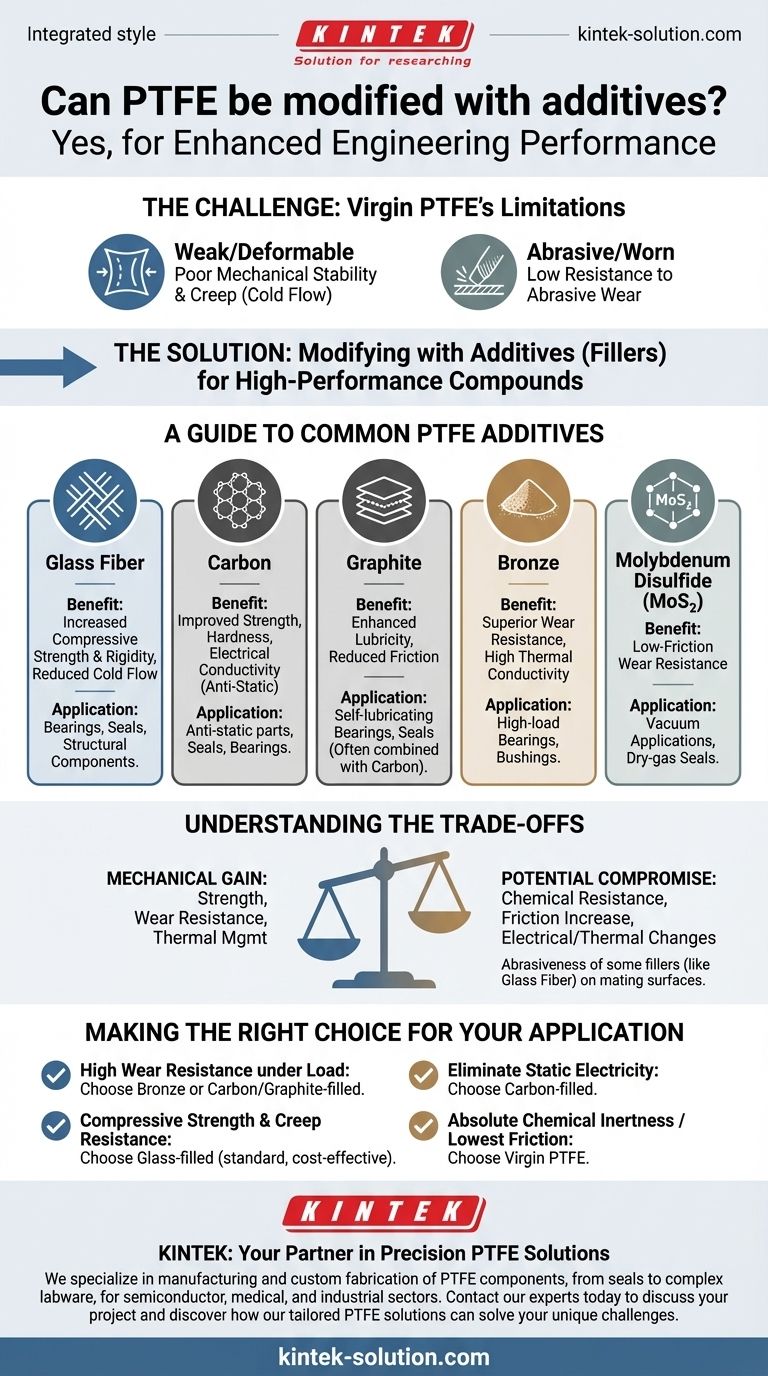

A Guide to Common PTFE Additives

Additives, also known as fillers, are blended with PTFE resin before it is processed. Each filler imparts a different set of properties to the final material.

Glass Fiber: For Strength and Rigidity

Glass fiber is one of the most common fillers. It significantly increases compressive strength and rigidity, drastically reducing cold flow. It also improves wear resistance.

Carbon: For Strength and Conductivity

Adding carbon improves compressive strength, hardness, and wear resistance. Critically, it also transforms PTFE from an excellent electrical insulator into a more conductive material, making it ideal for anti-static applications.

Graphite: For Enhanced Lubricity

Graphite is a solid lubricant that reduces the coefficient of friction of the compound and improves wear properties. It is often used in combination with other fillers like carbon to create a self-lubricating bearing material with excellent wear life.

Bronze: For Wear Resistance and Thermal Management

Bronze powder creates a compound with excellent wear resistance and high thermal conductivity. This allows heat generated at a bearing surface to dissipate, preventing thermal expansion and failure.

Molybdenum Disulfide (MoS₂): For Low-Friction Wear

Often called "Moly," this additive is another solid lubricant that enhances surface lubricity and wear resistance. It works particularly well in vacuum or dry-gas applications and is often used in small quantities alongside other fillers.

Understanding the Inevitable Trade-offs

Modifying PTFE is not a free lunch. Gaining a mechanical advantage almost always involves a compromise in another area.

Impact on Chemical Resistance

The near-universal chemical resistance of PTFE applies only to the virgin material. Fillers like bronze can be attacked by acids or corrosive chemicals, and glass can be affected by strong alkalis.

Changes in Frictional Properties

While still very low, the coefficient of friction for a filled PTFE is typically slightly higher than that of virgin PTFE. The primary goal is usually improving wear life, for which a minor increase in friction is an acceptable trade-off.

Altered Electrical and Thermal Properties

The most dramatic change is often in electrical properties. Adding carbon turns an insulator into a static-dissipative material. Conversely, fillers like bronze and carbon increase thermal conductivity, which is beneficial for managing frictional heat but undesirable for thermal insulation.

Abrasiveness and Mating Surfaces

Some fillers, particularly glass fiber, are abrasive. If a glass-filled PTFE bearing is run against a soft metal shaft (like aluminum), it can wear down the shaft over time. In these cases, less abrasive fillers like carbon/graphite are preferred.

Making the Right Choice for Your Application

Selecting the correct PTFE compound depends entirely on the primary challenge you need to solve.

- If your primary focus is high wear resistance under load: Consider a bronze or carbon/graphite-filled PTFE for superior durability and thermal management.

- If your primary focus is compressive strength and creep resistance: A glass-filled compound is the standard, cost-effective choice.

- If your primary focus is eliminating static electricity: A carbon-filled compound provides the necessary electrical conductivity.

- If your primary focus is absolute chemical inertness or lowest possible friction: Virgin PTFE remains the superior, and often only, option.

Understanding these compounds empowers you to move beyond a generic material callout and select the precise solution for your specific engineering problem.

Summary Table:

| Additive | Primary Benefit(s) | Common Applications |

|---|---|---|

| Glass Fiber | Increased compressive strength, rigidity, wear resistance | Bearings, seals, structural components |

| Carbon | Improved strength, wear resistance, electrical conductivity | Anti-static parts, bearings, seals |

| Bronze | Superior wear resistance, high thermal conductivity | High-load bearings, bushings |

| Graphite | Enhanced lubricity, wear resistance | Self-lubricating bearings, seals |

| Molybdenum Disulfide (MoS₂) | Low-friction wear resistance | Vacuum applications, dry-gas seals |

Need a high-performance PTFE component tailored to your specific requirements?

At KINTEK, we specialize in precision manufacturing and custom fabrication of PTFE components—from seals and liners to complex labware. Whether you need the absolute chemical purity of virgin PTFE or the enhanced mechanical properties of a filled compound for the semiconductor, medical, laboratory, or industrial sectors, we can help you select the right material and deliver from prototypes to high-volume orders.

Contact our experts today to discuss your project and discover how our tailored PTFE solutions can solve your unique engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the four types of Teflon resins and their key properties? Choose the Right Fluoropolymer for Your Application

- What quality control measures are used in PTFE production? Ensure Material Integrity for Your Application

- What are the key heat resistance properties of PTFE? Master Extreme Temperature Applications

- What role does PTFE play in automotive manufacturing? Enhancing Vehicle Durability and Efficiency

- What are the different types of Teflon available? A Guide to PTFE, FEP, PFA, and More

- What forms does expanded PTFE typically come in? Discover the Right ePTFE for Your Sealing & Filtration Needs

- How is Teflon made? The Science Behind Its Incredible Properties

- What are the common applications of Teflon? Discover Its Versatility Across Industries