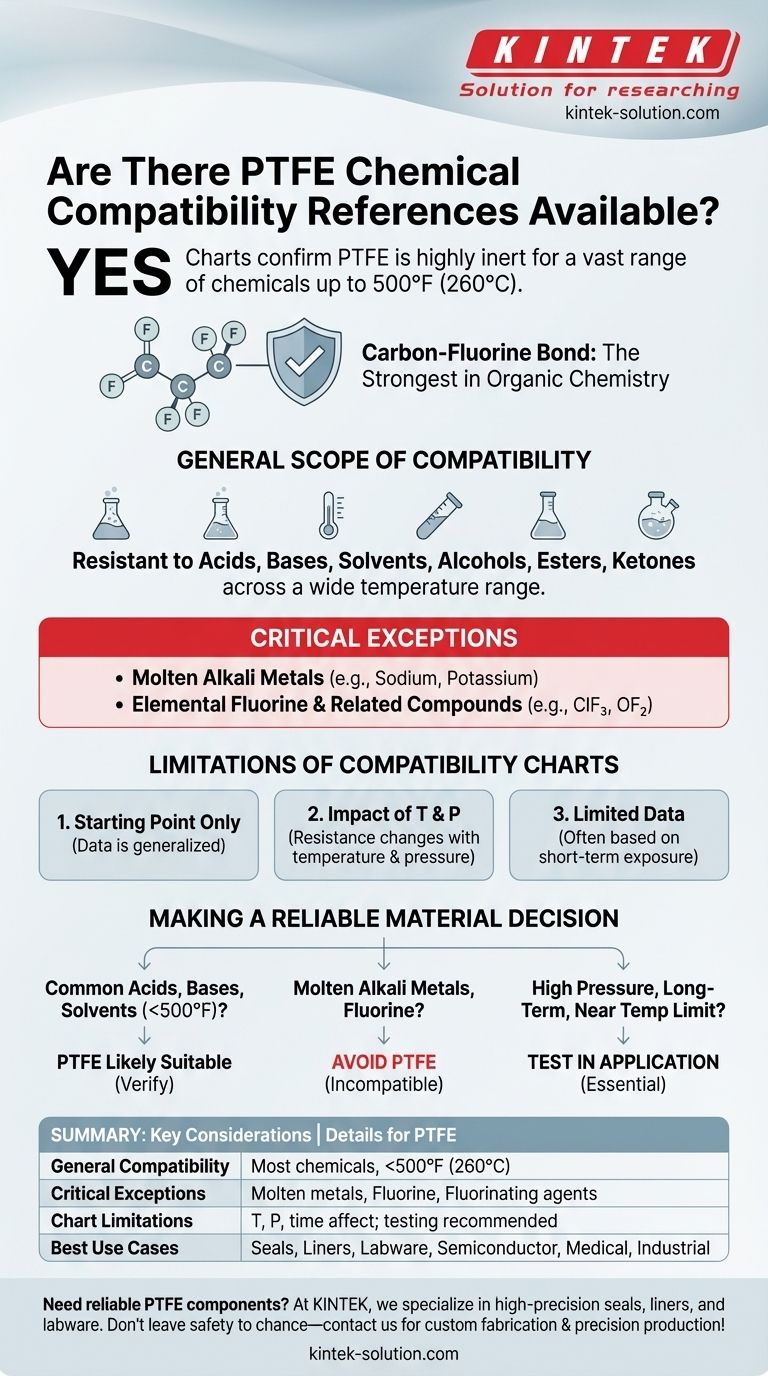

Yes, numerous chemical compatibility references for PTFE are available, typically in the form of charts and tables provided by manufacturers and industry suppliers. These resources confirm that Polytetrafluoroethylene (PTFE) is one of the most chemically inert polymers known, making it compatible with a vast range of acids, bases, and solvents up to its maximum operating temperature of approximately 500°F (260°C).

While PTFE offers near-universal chemical resistance, its compatibility is not absolute. Understanding the rare but critical exceptions and the inherent limitations of any compatibility chart is essential for avoiding catastrophic material failure in your application.

The Foundation of PTFE's Chemical Resistance

PTFE's exceptional performance stems from its unique molecular structure. This structure dictates its behavior when exposed to aggressive chemicals.

Why PTFE Is So Inert

The polymer is composed of a carbon chain fully shielded by a tight sheath of fluorine atoms. The carbon-fluorine bond is one of the strongest single bonds in organic chemistry.

This powerful bond and stable structure prevent most chemicals from attacking the polymer chain, rendering the material essentially inert.

General Scope of Compatibility

PTFE is resistant to nearly all industrial chemicals and solvents. This includes concentrated acids, strong alkalis, alcohols, esters, and ketones.

This broad compatibility holds true across a wide temperature range, a key reason for its widespread use in demanding environments like seals, gaskets, and linings.

Critical Exceptions: When PTFE Is Not Compatible

Despite its robust nature, a few substances can attack PTFE, typically under specific conditions like high temperatures. These exceptions are critical to know.

Molten Alkali Metals

Molten alkali metals, such as sodium and potassium, are highly reactive and can defluorinate the PTFE polymer, causing it to degrade.

Elemental Fluorine and Related Compounds

While PTFE is made with fluorine, it can be attacked by fluorine itself. Gaseous fluorine, particularly if turbulent, and certain highly reactive fluorinating agents will break down the polymer.

Examples include chlorine trifluoride (ClF₃) and oxygen difluoride (OF₂), especially at elevated temperatures and pressures.

Understanding the Limitations of Compatibility Charts

Chemical compatibility charts are invaluable tools, but they are not infallible guarantees of performance. Treating them as absolute truth is a common and dangerous pitfall.

Charts as a Starting Point, Not a Guarantee

A chart should only be used as an initial guide for material selection. The data is often generalized and may not reflect the nuances of your specific operating environment.

The Impact of Temperature and Pressure

The resistance of PTFE can change with temperature, pressure, and chemical concentration. A rating at room temperature may not be valid near the material's upper service limit.

Limited Exposure Data

Many charts are based on short-term exposure tests, sometimes as short as 48 hours. This data provides no information about the effects of long-term immersion, which can be critical for applications like seals or tank linings.

The Necessity of Application-Specific Testing

Because of these variables, you must conduct your own tests under conditions that precisely mimic your application. This is the only way to ensure full compatibility and long-term reliability.

Making a Reliable Material Decision

Your final choice should be based on a clear understanding of your specific chemical environment and the known limitations of PTFE.

- If your primary focus is on containing common acids, bases, or solvents below 500°F (260°C): PTFE is very likely a suitable and highly reliable choice, but you should still consult a chart for initial verification.

- If your application involves molten alkali metals, fluorine gas, or specific fluorinating agents: You must avoid PTFE, as it is known to be incompatible with these substances.

- If your application involves high pressures, long-term exposure, or operates near PTFE's temperature limit: You must treat compatibility charts as a preliminary guide and conduct your own real-world tests to validate performance.

Ultimately, your own testing under true operating conditions is the final arbiter of material suitability.

Summary Table:

| Key Consideration | Details for PTFE |

|---|---|

| General Compatibility | Resistant to most acids, bases, solvents up to 500°F (260°C) |

| Critical Exceptions | Molten alkali metals, elemental fluorine, and certain fluorinating agents |

| Chart Limitations | Temperature, pressure, and exposure time can affect performance; testing is recommended |

| Best Use Cases | Seals, liners, and labware for semiconductor, medical, and industrial applications |

Need reliable PTFE components for your critical application?

At KINTEK, we specialize in manufacturing high-precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures that your components are not only chemically compatible but also built to perform under your specific operating conditions—whether you need custom prototypes or high-volume orders.

Don't leave material safety to chance—contact us today to discuss your requirements and benefit from our precision production and custom fabrication services!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How do fillers affect PTFE properties? Transform PTFE into a High-Performance Material

- What are the primary applications of PTFE in electrical and aerospace industries? Ensure Reliability in Extreme Environments

- Why are fillers added to PTFE? Enhance Performance for Demanding Applications

- What are the general properties of Polytetrafluoroethylene (PTFE)? Master Its Strengths and Limitations

- What are the key properties of PTFE? A Guide to Its High-Performance Versatility

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What are the limitations of PTFE? Understanding Creep, Abrasion, and Radiation Weaknesses

- How does PTFE perform when exposed to different types of water? Unmatched Chemical Resistance in Any Aqueous Environment