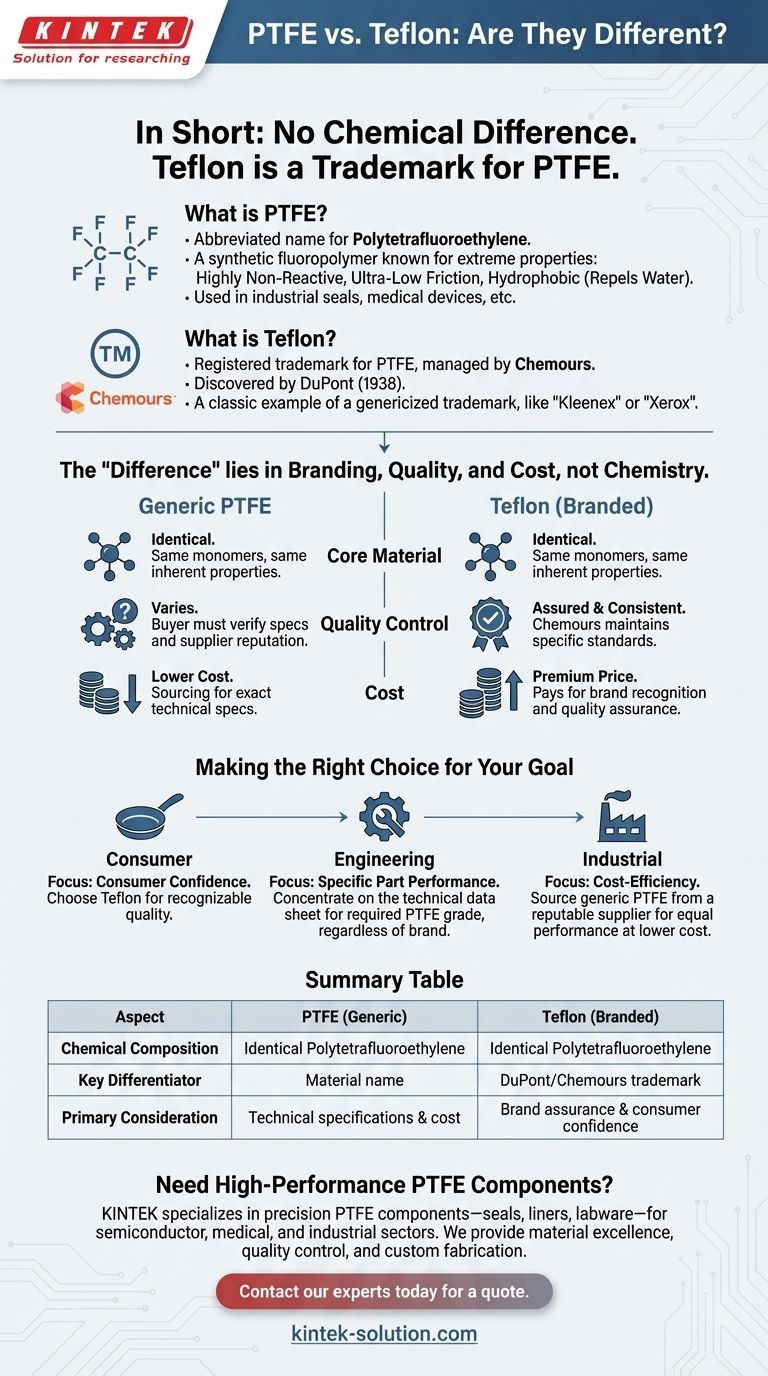

In short, there is no chemical difference between PTFE and Teflon. They are two names for the exact same material. Teflon is simply the well-known trademarked brand name for the polymer Polytetrafluoroethylene, or PTFE for short.

The core issue isn't about choosing between two different materials, but understanding the relationship between a generic chemical (PTFE) and a famous brand name (Teflon). The material itself is identical; the difference lies in branding, quality assurance, and how it's marketed.

The Origin of the Confusion: A Tale of Two Names

Many people believe PTFE and Teflon are competitors or different versions of the same material. This common misconception stems from the widespread success of one company's brand name becoming synonymous with the product itself.

What is PTFE?

PTFE is the abbreviated chemical name for Polytetrafluoroethylene. It is a synthetic fluoropolymer of tetrafluoroethylene.

This material is known for its extreme properties: it is highly non-reactive, has one of the lowest coefficients of friction of any solid, and is hydrophobic (it repels water). These traits make it incredibly useful in everything from industrial seals to medical devices.

What is Teflon?

Teflon is the registered trademark for PTFE, discovered by DuPont in 1938 and now managed by its spin-off company, Chemours.

Because of its early introduction and powerful marketing, especially in non-stick cookware, the name "Teflon" became a household term. This is a classic example of a brand name becoming a genericized trademark, much like people refer to all facial tissues as "Kleenex" or all photocopies as "Xerox."

Does the Brand Name "Teflon" Imply a Difference?

While the base polymer is identical, the branding can have practical implications for a buyer. The distinction is not in the chemistry, but in the manufacturing, quality control, and potential cost.

The Core Material is Identical

At a molecular level, the PTFE in a product marketed as Teflon is the same as the PTFE in a product from another manufacturer. Both are formed from the same monomers and possess the same inherent properties of low friction and chemical resistance.

The Role of Quality Control

The primary advantage of a branded product like Teflon is the assurance of consistent quality. Chemours maintains specific manufacturing standards and quality control processes for any product bearing its trademark.

When purchasing generic PTFE, the quality can vary between manufacturers. While many produce high-quality PTFE, it places the burden on the buyer to verify the material specifications and the supplier's reputation.

Impact on Cost

Branded Teflon products often carry a higher price tag. This premium is for the brand recognition, marketing, and the quality assurance that comes with the name.

For many industrial applications where a specific grade of PTFE is required, engineers can source generic PTFE that meets the exact same technical specifications at a lower cost.

Making the Right Choice for Your Goal

Understanding this distinction allows you to make a more informed decision based on your specific needs, rather than getting caught up in the naming.

- If your primary focus is consumer confidence (e.g., buying a non-stick pan): The Teflon brand provides a recognizable mark of quality and performance, making it a straightforward choice.

- If your primary focus is engineering a specific part: You should concentrate on the technical data sheet for the required grade of PTFE, regardless of whether it is branded as Teflon or sourced from another supplier.

- If your primary focus is cost-efficiency for industrial use: Sourcing generic PTFE from a reputable supplier can provide the exact same performance as a branded product for a lower price.

Ultimately, your decision should be based on the material's specified properties and the manufacturer's reputation, not on the name alone.

Summary Table:

| Aspect | PTFE (Generic) | Teflon (Branded) |

|---|---|---|

| Chemical Composition | Identical Polytetrafluoroethylene | Identical Polytetrafluoroethylene |

| Key Differentiator | Material name | DuPont/Chemours trademark |

| Primary Consideration | Technical specifications & cost | Brand assurance & consumer confidence |

Need High-Performance PTFE Components?

Understanding the nuances between material names and brands is crucial for selecting the right component for your application. KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We provide the material excellence you require, with the quality control and custom fabrication (from prototypes to high-volume orders) to ensure optimal performance and cost-efficiency.

Contact our experts today to discuss your PTFE needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does the temperature range of RPTFE compare to other PTFE materials? Maximize Performance Under Load

- What are some emerging applications of PTFE? Discover Its Critical Role in Aerospace, Medical, and Semiconductor Tech

- What does PTFE coating thickness refer to? The Key to Durability and Performance

- How is FEP Teflon different from other types in terms of properties? The Key is Fabrication Flexibility

- What are the temperature range and mechanical properties of PTFE? The Ultimate Guide to Performance

- What are the industrial applications of PTFE? Unlock High-Performance in Extreme Environments

- What are the future trends in PTFE molding technology? Unlock Advanced Performance with 3D Printing & Nanocomposites

- Why is PTFE's low friction coefficient significant? Unlock Superior Efficiency and Longevity