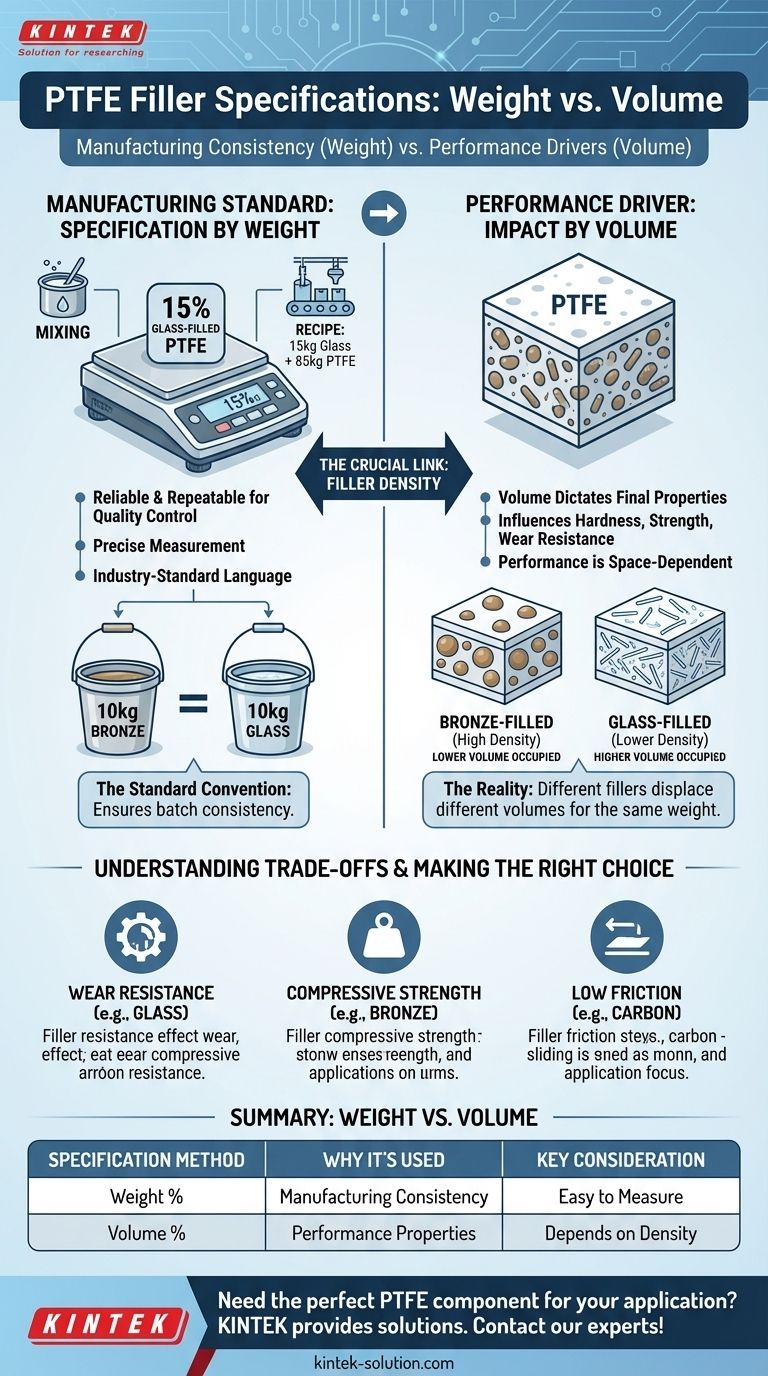

To be direct, Polytetrafluoroethylene (PTFE) filler specifications are almost universally defined by weight percentage. This is the standard convention for blending and manufacturing consistency. However, the resulting physical and mechanical properties of the final material are dictated by the volume that the filler occupies within the PTFE matrix.

While the recipe is written by weight, the performance is determined by volume. The crucial variable connecting the two is the density of the filler material, which is why a 25% glass-filled compound behaves very differently from a 25% bronze-filled compound.

The Standard: Specification by Weight

Why Weight is the Manufacturing Standard

In any industrial compounding process, measuring ingredients by weight is the most reliable and repeatable method. It ensures that every batch of material receives the exact same ratio of raw materials, which is critical for quality control.

Scales are precise and easy to calibrate, whereas measuring bulk powders or fibers by volume can be highly inconsistent due to variations in compaction and particle size.

Interpreting a Specification Sheet

When you see a material listed as "15% Glass-Filled PTFE," it means that for every 100 kilograms of the compound, 15 kilograms are glass fiber and 85 kilograms are virgin PTFE resin. This is the industry-standard language.

Why Volume is the Performance Driver

The Critical Role of Density

The core issue is that different fillers have vastly different densities. For instance, bronze is significantly denser than carbon or glass.

This means that the same weight percentage of two different fillers will displace a completely different volume within the PTFE.

How Volume Impacts Material Properties

It is the volume of filler, not its weight, that directly influences the compound's final characteristics.

The volume of filler particles determines how much they interfere with the PTFE matrix's ability to deform, creep, and wear. A higher volume of filler generally leads to increased hardness, better compressive strength, and improved wear resistance.

A Practical Analogy: Glass vs. Bronze

Imagine you have two identical buckets. In the first, you add 10kg of heavy, dense bronze powder. In the second, you add 10kg of lighter, less-dense milled glass fiber.

Although the weight is identical, the glass fiber will take up much more space (volume) in its bucket. The same principle applies inside the PTFE matrix, fundamentally changing the material's performance.

Understanding the Trade-offs

The Danger of Direct Comparison

A common mistake is assuming that two compounds with the same filler percentage by weight will have similar performance enhancements.

A "25% fill" is not a universal measure of performance. A 25% carbon-filled PTFE has a high volume of filler and will exhibit excellent wear characteristics, while a 25% bronze-filled PTFE has a lower volume of filler but offers superior thermal conductivity and compressive strength due to the properties of the bronze itself.

Focusing on Application, Not Just Percentage

Engineers must look beyond the weight percentage and consider the properties of the filler material and the volume it will occupy. The choice must be driven entirely by the demands of the specific application.

Making the Right Choice for Your Goal

When evaluating PTFE compounds, it is critical to align the filler's properties and its volumetric presence with your primary engineering objective.

- If your primary focus is wear resistance and chemical compatibility: A glass-filled compound is a balanced, all-around choice where the weight-to-volume ratio provides a good structure.

- If your primary focus is maximum compressive strength and thermal conductivity: A bronze-filled compound is superior, but remember its high density means a given weight percentage occupies less volume than other fillers.

- If your primary focus is low friction and improved wear life in non-abrasive environments: A carbon-filled compound is an excellent choice, as its low density provides a high volume of performance-enhancing particles for a given weight.

Ultimately, understanding the interplay between specification (weight) and performance (volume) empowers you to select a material based on its true engineering properties, not just its recipe.

Summary Table:

| Specification Method | Why It's Used | Key Consideration |

|---|---|---|

| Weight Percentage | Standard for manufacturing consistency and quality control. | Easy to measure and repeat in batching. |

| Volume Percentage | Dictates final mechanical properties and performance. | Depends on filler density (e.g., glass vs. bronze). |

Need a PTFE component with precisely the right properties for your application?

At KINTEK, we don't just supply materials—we provide solutions. Our expertise in custom PTFE fabrication for the semiconductor, medical, laboratory, and industrial sectors means we understand the critical relationship between filler specifications and real-world performance.

We can help you select or develop a PTFE compound—whether filled with glass, bronze, carbon, or other materials—that delivers the exact wear resistance, compressive strength, or thermal conductivity your project demands. From prototypes to high-volume production, we prioritize precision to ensure your components perform flawlessly.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are PTFE Bellows seals and where are they commonly used? The Ultimate Guide to Corrosive Fluid Sealing

- What material properties make PTFE suitable for oil seals? Superior Performance in Extreme Conditions

- What are some filler materials used with PTFE to enhance its properties? A Guide to Reinforced PTFE

- Why are PTFE O-rings preferred for sealing systems? Superior Chemical & Thermal Resistance

- What are some medical applications of PTFE energized seals? Ensuring Reliability and Purity in Medical Devices

- Why are PTFE Bellows suitable for electroplating processes? Master Harsh Chemical & Thermal Environments

- Why are ePTFE gaskets not recommended for abrasive environments? Protect Your Seals from Premature Failure

- How do spring energized PTFE seals provide consistent sealing force? A Reliable Solution for Demanding Applications