Selecting the optimal septa material for reactive substance handling is critical for maintaining sample integrity, preventing contamination, and ensuring operational safety. This guide compares chemical resistance, temperature thresholds, and real-world performance to help you make an informed decision—especially in aggressive environments like pharmaceutical testing or semiconductor manufacturing.

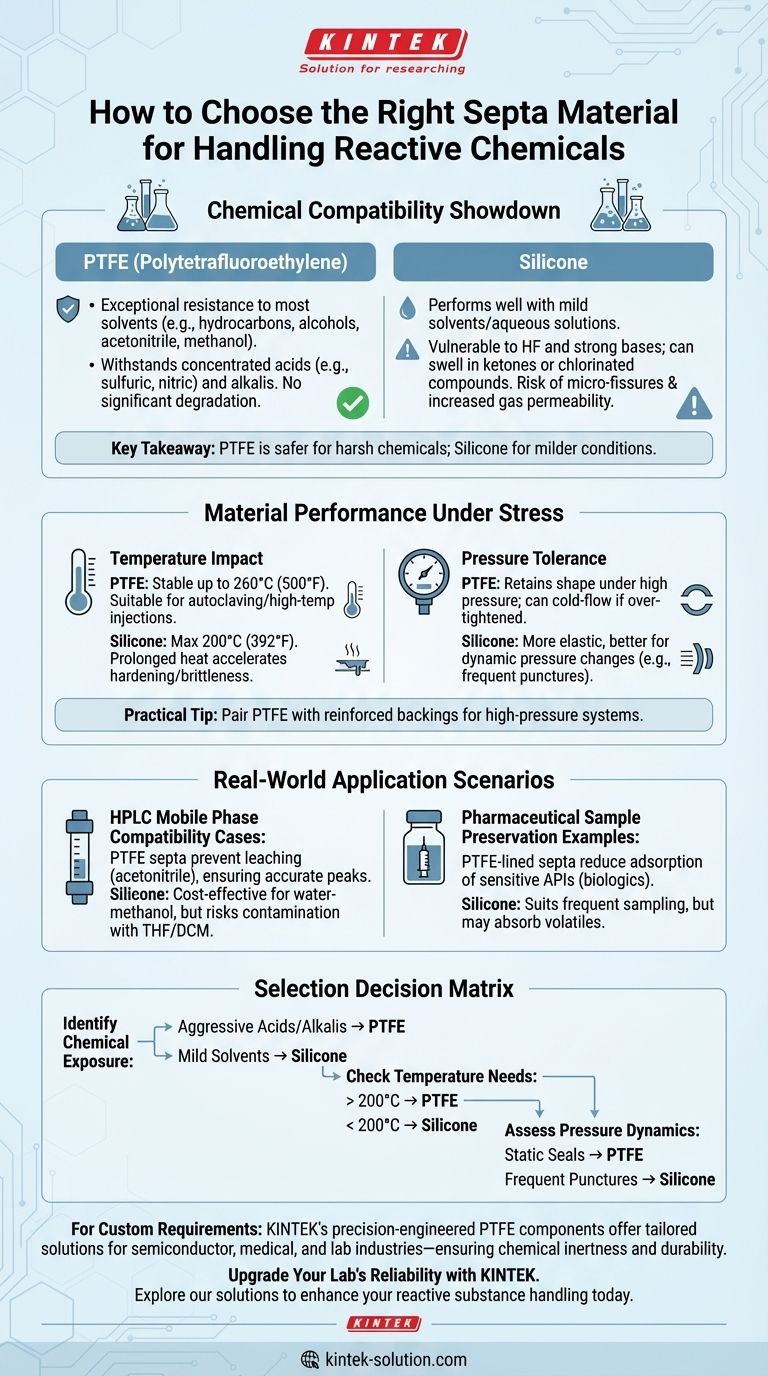

Chemical Compatibility Showdown

When handling reactive substances, the septa material must resist degradation from solvents, acids, or alkalis. Here’s how common materials compare:

Critical Differences in Solvent Resistance

- PTFE (Polytetrafluoroethylene):

- Exceptional resistance to most solvents, including hydrocarbons and alcohols.

- Ideal for HPLC mobile phases containing acetonitrile or methanol.

- Silicone:

- Performs well with mild solvents but swells in ketones or chlorinated compounds.

- Better suited for aqueous solutions than aggressive organic solvents.

Acid/Alkaline Exposure Thresholds

- PTFE: Withstands concentrated acids (e.g., sulfuric, nitric) and alkalis without significant degradation.

- Silicone: Vulnerable to hydrofluoric acid (HF) and strong bases, leading to permeability changes over time.

- Reference: Studies show silicone septa exposed to 40% HF may develop micro-fissures, increasing gas permeability.

Key Takeaway: PTFE is the safer choice for harsh acids, while silicone works for milder conditions.

Material Performance Under Stress

Beyond chemical resistance, temperature and pressure impact septa longevity.

Temperature Impact on Degradation Rates

- PTFE: Stable up to 260°C (500°F), making it suitable for autoclaving or high-temperature injections.

- Silicone: Max 200°C (392°F); prolonged heat accelerates hardening and brittleness.

Example: In semiconductor processing, PTFE septa maintain seal integrity during vacuum chamber heating, whereas silicone may fail.

Pressure Tolerance Comparison

- PTFE: Retains shape under high pressure but can cold-flow (deform) if over-tightened.

- Silicone: More elastic, better for dynamic pressure changes (e.g., syringe punctures in GC/MS).

Practical Tip: Pair PTFE with reinforced backings for high-pressure systems.

Real-World Application Scenarios

HPLC Mobile Phase Compatibility Cases

- PTFE septa prevent leaching when handling acetonitrile-based phases, ensuring accurate peak detection.

- Silicone is cost-effective for water-methanol mixes but risks contamination with THF or DCM.

Pharmaceutical Sample Preservation Examples

- PTFE-lined septa in vial closures reduce adsorption of sensitive APIs (e.g., biologics).

- Silicone’s flexibility suits frequent-sampling workflows but may absorb volatile compounds.

Selection Decision Matrix

Use this flowchart to narrow down options:

- Identify Chemical Exposure:

- Aggressive acids/alkalis → PTFE

- Mild solvents → Silicone

- Check Temperature Needs:

-

200°C → PTFE

- <200°C → Silicone

- Assess Pressure Dynamics:

- Static seals → PTFE

- Frequent punctures → Silicone

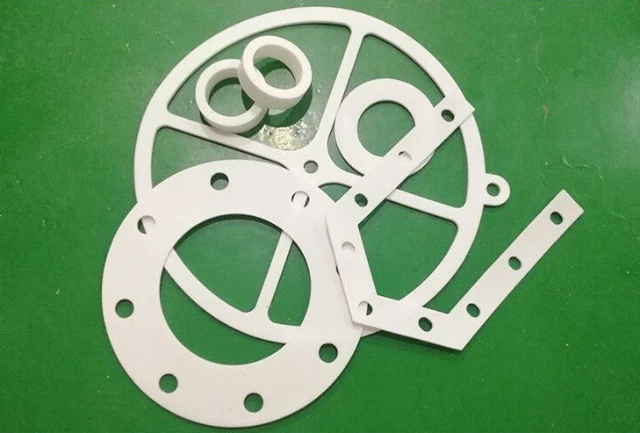

For Custom Requirements: KINTEK’s precision-engineered PTFE components offer tailored solutions for semiconductor, medical, and lab industries—ensuring chemical inertness and durability even in extreme conditions.

Upgrade Your Lab’s Reliability with KINTEK

Choosing the right septa material safeguards your processes and data integrity. Whether you need high-temperature PTFE seals or flexible silicone closures, KINTEK delivers precision-manufactured components tailored to your industry’s demands. [Explore our solutions] to enhance your reactive substance handling today.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems