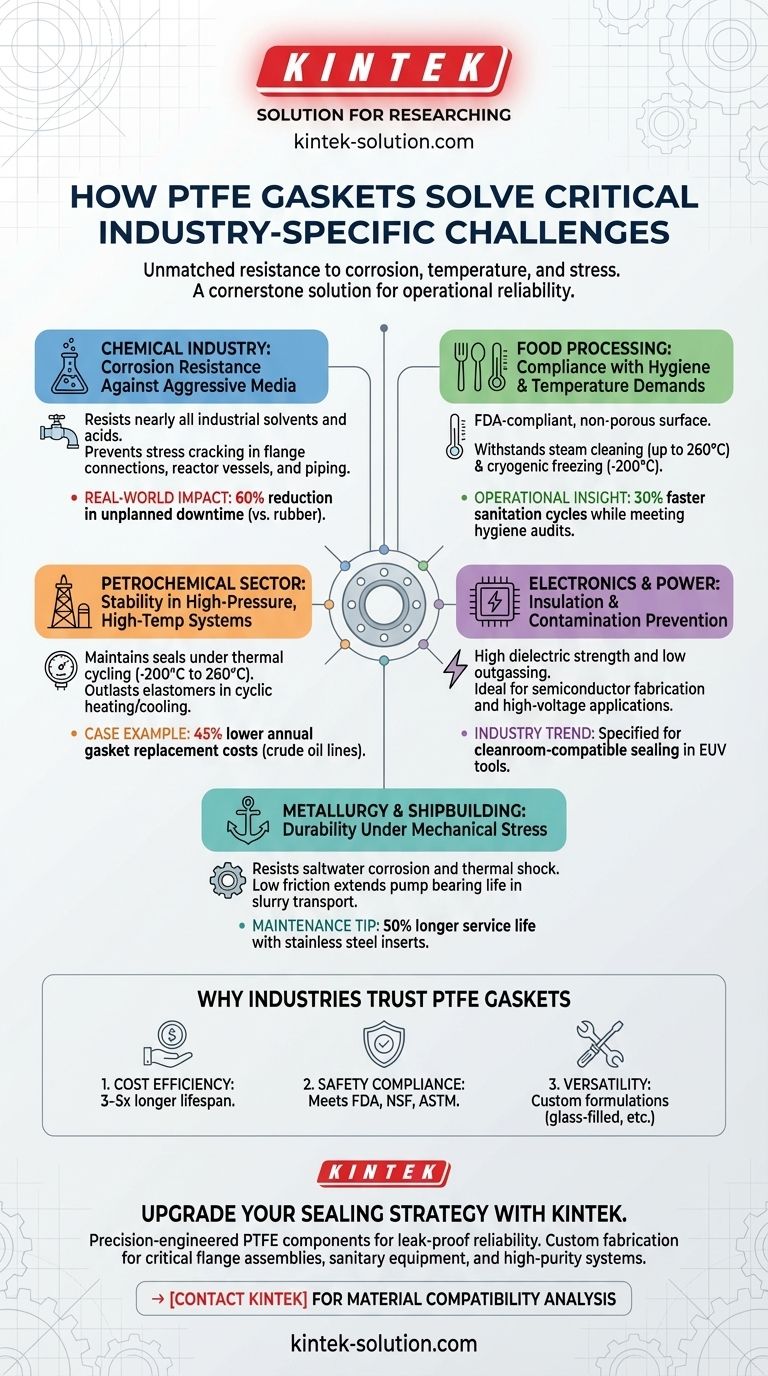

When operational reliability is non-negotiable, PTFE (polytetrafluoroethylene) gaskets emerge as a cornerstone solution across industries. Their unique molecular structure delivers unmatched resistance to corrosion, temperature extremes, and mechanical stress—directly addressing the pain points of chemical processing, food production, petrochemical operations, and beyond. Here’s how these engineered components transform industry-specific challenges into operational advantages.

PTFE Gaskets in Harsh Environments: A Cross-Industry Analysis

Chemical Industry: Corrosion Resistance Against Aggressive Media

PTFE gaskets excel in environments where sulfuric acid, chlor-alkali, and other aggressive chemicals degrade conventional materials. Research shows PTFE is the most chemically inert polymer, resisting nearly all industrial solvents and acids. This property prevents stress cracking and seal failures in:

- Flange connections handling concentrated acids

- Reactor vessels with prolonged chemical exposure

- Piping systems transporting corrosive fluids

Real-world impact: A chemical plant using PTFE gaskets reported a 60% reduction in unplanned downtime over 18 months compared to rubber-based alternatives.

Food Processing: Compliance with Hygiene and Temperature Demands

PTFE’s FDA-compliant, non-porous surface eliminates bacterial harborage points—a critical need for dairy, meat, and beverage processing. Key benefits include:

- Temperature resilience: Withstands steam cleaning (up to 260°C/500°F) and cryogenic freezing (-200°C/-328°F)

- Non-stick properties: Prevents product buildup, reducing contamination risks

- Chemical inertness: Tolerates harsh sanitizers like chlorine and peroxide

Operational insight: Food manufacturers using PTFE gaskets achieve 30% faster sanitation cycles while meeting stringent hygiene audits.

Petrochemical Sector: Stability in High-Pressure, High-Temperature Systems

In refineries and pipelines, PTFE gaskets maintain seals under thermal cycling (from -200°C to 260°C) and moderate pressures. However, note their limitations:

- Best for moderate-pressure systems (metal-reinforced PTFE hybrids address higher pressures)

- Thermal stability: Outlasts elastomers in cyclic heating/cooling, reducing flange resealing frequency

Case example: A Gulf Coast refinery cut gasket replacement costs by 45% annually after switching to PTFE for crude oil transfer lines.

Electronics and Electric Power: Insulation and Contamination Prevention

PTFE’s dielectric strength (high electrical resistance) and low outgassing make it ideal for:

- Semiconductor fabrication: Seals in CVD chambers resist plasma erosion

- Transformer gaskets: Prevent moisture ingress and arcing

- High-voltage applications: Minimal carbon tracking risk

Industry trend: Leading chipmakers now specify PTFE gaskets for cleanroom-compatible sealing in EUV lithography tools.

Metallurgy and Shipbuilding: Durability Under Mechanical Stress

While PTFE isn’t optimal for ultra-high-pressure hydraulics, it outperforms in:

- Marine engine gaskets: Resists saltwater corrosion better than graphite composites

- Steel mill equipment: Handles thermal shock from quenching processes

- Pump seals: Low friction extends bearing life in slurry transport

Maintenance tip: Pair PTFE with stainless steel inserts for 50% longer service life in vibrating machinery.

Why Industries Trust PTFE Gaskets

- Cost efficiency: 3–5x longer lifespan than rubber or compressed fiber gaskets

- Safety compliance: Meets FDA, NSF, and ASTM standards out-of-the-box

- Versatility: Custom formulations (glass-filled, virgin, etc.) for niche requirements

"The right gasket shouldn’t just seal—it should solve."

Upgrade Your Sealing Strategy with KINTEK

From semiconductor labs to food-grade pipelines, KINTEK’s precision-engineered PTFE components deliver leak-proof reliability tailored to your industry’s demands. Our custom fabrication ensures exact fits for:

- Critical flange assemblies

- Sanitary process equipment

- High-purity fluid systems

→ [Contact KINTEK] to request a material compatibility analysis for your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics