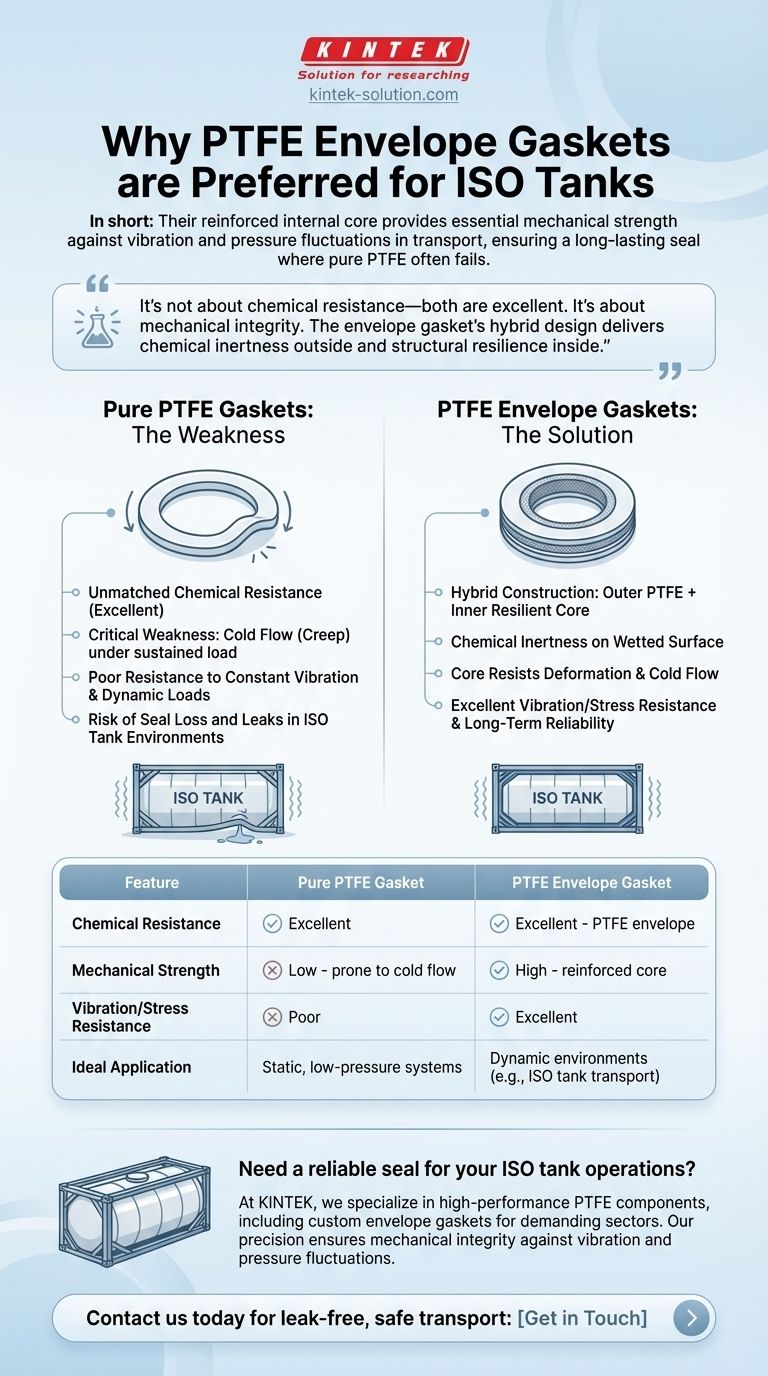

To put it simply, PTFE envelope gaskets are preferred over pure PTFE gaskets in ISO tanks because their reinforced internal core provides essential mechanical strength. This strength prevents the gasket from deforming under the constant vibration and pressure fluctuations inherent in transport, ensuring a reliable and long-lasting seal where a pure PTFE gasket would likely fail.

The decision between pure PTFE and a PTFE envelope gasket for an ISO tank is not about chemical resistance—both are excellent. It is a choice about mechanical integrity. The envelope gasket's hybrid design delivers the chemical inertness of PTFE on the outside and the crucial structural resilience of a reinforced core on the inside.

The Unique Sealing Challenges of ISO Tanks

Understanding the gasket's operating environment is critical. ISO tanks are not static vessels; they are subjected to significant and unpredictable forces that place extreme demands on any sealing component.

Constant Vibration and Dynamic Loads

An ISO tank is constantly in motion, whether on a truck, train, or ship. This subjects the flange and gasket to continuous vibration and mechanical stress, which can easily compromise a weak seal over time.

Pressure and Temperature Fluctuations

The internal pressure of a tank can change dramatically during loading, unloading, and due to ambient temperature swings. A gasket must be able to maintain its sealing force despite these cycles to prevent leaks.

Aggressive and Sensitive Cargo

ISO tanks carry everything from corrosive industrial chemicals to high-purity food products. The gasket material must be chemically inert to avoid being degraded by the cargo and, just as importantly, to prevent contaminating the cargo.

Analyzing Pure PTFE's Material Properties

Pure Polytetrafluoroethylene (PTFE) is an exceptional material, but its strengths and weaknesses must be understood in the context of the application.

The Benefit: Unmatched Chemical Resistance

PTFE is one of the most chemically inert substances known. It can withstand a vast range of aggressive chemicals, making it a default choice for wetted surfaces. It is also non-toxic and FDA-compliant, perfect for food and pharmaceutical use.

The Critical Weakness: Cold Flow

The primary drawback of pure PTFE is its tendency to "creep" or "cold flow." Under sustained mechanical pressure, like the bolt load on a flange, the material slowly deforms and moves away from the pressure point. In an ISO tank, this causes a loss of sealing stress, leading to inevitable leaks.

The Engineering Solution: The PTFE Envelope Gasket

The PTFE envelope gasket was designed specifically to overcome the mechanical limitations of pure PTFE while retaining its chemical benefits.

A Hybrid Construction

This gasket consists of two components: a soft, resilient core material (the insert) and a thin outer layer of pure PTFE (the envelope) that completely encapsulates it.

Best of Both Worlds

The outer PTFE envelope is the only part that touches the chemical cargo, providing the necessary universal chemical resistance and preventing product contamination.

The Core's Role: Resisting Deformation

The inner core provides the mechanical strength and recovery that pure PTFE lacks. It pushes back against the flange surfaces, resists the effects of vibration, and maintains a consistent sealing force even as pressures and temperatures change. This core is what stops the gasket from failing.

Understanding the Trade-offs

While the envelope gasket is a superior solution for ISO tanks, it's important to understand the complete picture.

When Pure PTFE Might Suffice

For static, low-pressure laboratory or plant applications where vibration is not a factor, a simple pure or expanded PTFE gasket can perform perfectly well. The complexity of the envelope gasket is a direct solution to dynamic stress.

Expanded PTFE as an Alternative

Expanded PTFE (ePTFE) is another option that improves upon pure PTFE. Its porous, fibrous structure gives it better flexibility and compression resilience, allowing it to conform to irregular surfaces. However, for the high-impact, high-vibration environment of an ISO tank, the robust core of an envelope gasket typically provides greater long-term reliability.

The Importance of the Core

The choice of core material within the envelope gasket matters. Different cores are used for different temperature and pressure ratings. The core must have the mechanical properties to handle the application's demands, even though it is protected from the chemical media.

Making the Right Choice for Your Goal

Selecting the correct gasket is fundamental to ensuring safety, preventing cargo loss, and minimizing maintenance.

- If your primary focus is operational safety and reliability: The PTFE envelope gasket is the definitive choice for ISO tanks, as its reinforced core is engineered to withstand dynamic loads and prevent seal failure.

- If you are handling high-purity or corrosive media: The PTFE envelope provides a completely inert sealing surface, protecting your product's integrity while the core maintains a secure seal.

- If you are evaluating cost vs. performance: The slightly higher initial cost of an envelope gasket is easily offset by reduced maintenance costs and the prevention of leaks, which can be extremely expensive in terms of lost product, cleanup, and safety incidents.

Ultimately, choosing a gasket based on its mechanical resilience for the specific application is the key to safe and efficient ISO tank operation.

Summary Table:

| Feature | Pure PTFE Gasket | PTFE Envelope Gasket |

|---|---|---|

| Chemical Resistance | Excellent | Excellent (PTFE envelope) |

| Mechanical Strength | Low (prone to cold flow) | High (reinforced core) |

| Vibration/Stress Resistance | Poor | Excellent |

| Ideal Application | Static, low-pressure systems | Dynamic environments (e.g., ISO tank transport) |

Need a reliable seal for your ISO tank operations?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets designed for the demanding conditions of the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your gaskets provide the mechanical integrity to withstand vibration and pressure fluctuations, protecting your sensitive or corrosive cargo during transport.

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications. Contact us today to discuss your application and ensure leak-free, safe transport: Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications