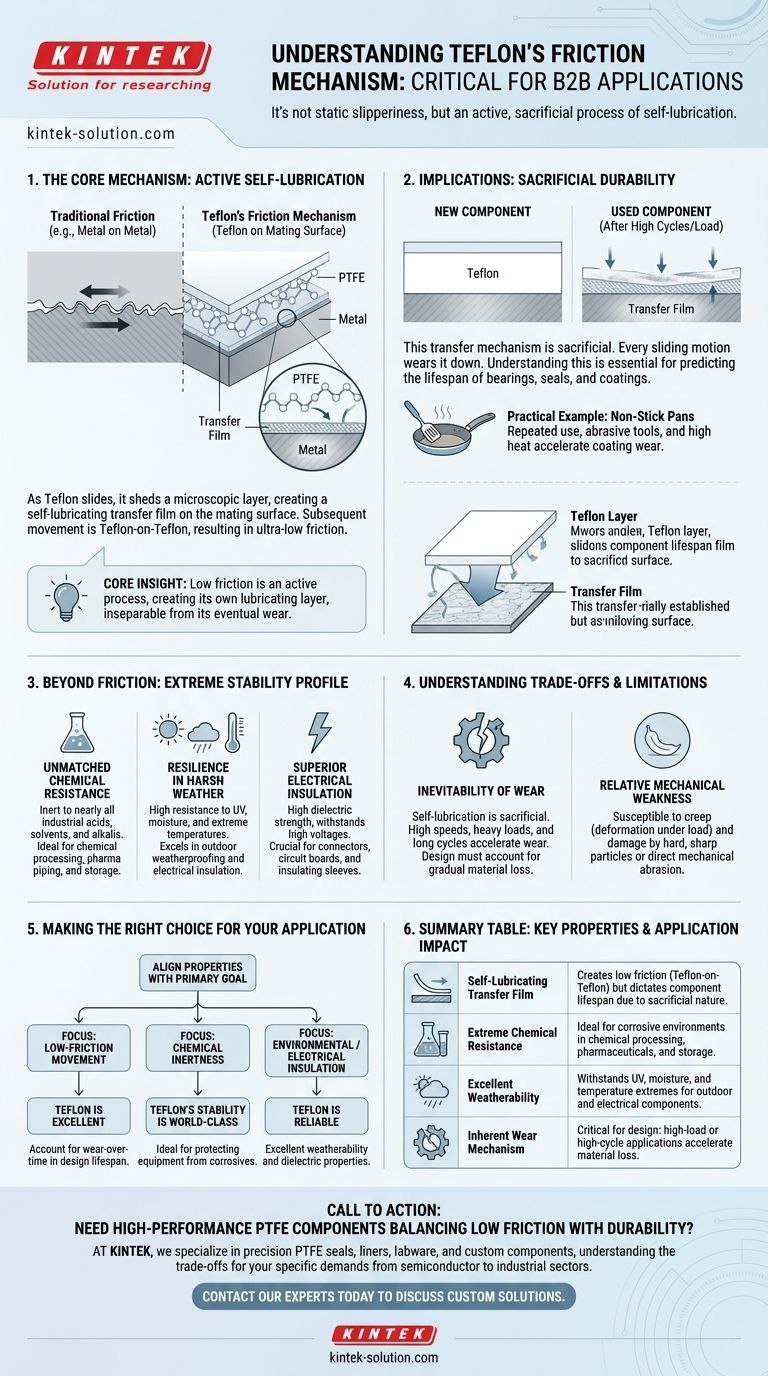

Understanding Teflon's friction mechanism is critical because its performance is not based on a static "slipperiness," but on an active process of self-sacrifice. As Teflon slides, it sheds a microscopic layer onto the mating surface, creating a self-lubricating film. This transfer mechanism is the true source of its uniquely low friction, but it also dictates the material's durability and lifespan, making it a crucial factor in assessing its suitability for any application.

The core insight is that Teflon's low friction is not an inherent surface state but an active process. It works by creating its own lubricating layer, a mechanism that is inseparable from its eventual wear.

The Core Mechanism: More Than Just a Slippery Surface

To properly apply Teflon, or Polytetrafluoroethylene (PTFE), you must move beyond the simple idea of a non-stick surface and understand the dynamic process that occurs at the microscopic level.

The Self-Lubricating Transfer Film

When Teflon slides against another surface, it doesn't simply glide over it. Instead, it deposits a very thin, ordered film of its own molecules onto the opposing material.

This "transfer film" becomes the new surface. Subsequent movement is no longer Teflon sliding against metal, plastic, or ceramic; it is Teflon sliding against Teflon, which results in an extremely low coefficient of friction.

Implications for Durability

This mechanism directly impacts the material's lifespan. Because Teflon must physically transfer a layer of itself to function effectively, it is a sacrificial material by nature.

Every sliding motion wears it down, however slightly. Understanding this is essential for predicting the durability and service life of components like bearings, seals, or non-stick coatings.

Why This Matters for Non-Stick Pans

A non-stick pan is a perfect practical example. The Teflon coating works by creating this transfer film, preventing food from bonding to the metal pan.

However, repeated use of abrasive utensils or high heat accelerates the degradation and removal of this coating, which is why non-stick performance diminishes over time.

Beyond Friction: A Profile of Extreme Stability

Teflon's unique friction mechanism is only useful because the material itself can survive in demanding environments. Its other properties allow it to be deployed where other low-friction materials would fail.

Unmatched Chemical Resistance

Teflon is exceptionally inert and remains stable when exposed to nearly all industrial acids, solvents, and alkalis.

This makes it invaluable for equipment in chemical processing, pharmaceutical piping, and storage tank linings where preventing corrosion and maintaining material purity are paramount.

Resilience in Harsh Weather

With high resistance to UV radiation, moisture, and extreme temperatures, Teflon excels in outdoor applications.

It is frequently used for weatherproofing components, coating wires and cables, and as electrical insulators that must withstand constant environmental exposure without degrading.

Superior Electrical Insulation

Teflon possesses a high dielectric strength, meaning it is an excellent electrical insulator that can withstand high voltages.

This property is crucial for components like connectors, circuit board substrates, and insulating sleeves where preventing electrical current leakage is a primary design requirement.

Understanding the Trade-offs

No material is perfect. Acknowledging Teflon's limitations is just as important as leveraging its strengths. Its core friction mechanism is also the source of its primary weaknesses.

The Inevitability of Wear

As previously established, the self-lubricating process is inherently sacrificial. Applications involving high speeds, heavy loads, or long duty cycles will accelerate this wear.

Designers must account for this gradual material loss to ensure the component functions reliably throughout its intended lifespan.

Relative Mechanical Weakness

While chemically robust, Teflon is a relatively soft polymer. It is susceptible to "creep" (slow deformation under load) and can be damaged by hard, sharp particles.

While it resists weathering abrasion well, direct mechanical abrasion can quickly compromise the integrity of a Teflon coating or part.

Making the Right Choice for Your Application

To select the right material, you must align its properties with your primary operational goal.

- If your primary focus is low-friction movement: Teflon is an excellent choice, but you must account for its wear-over-time mechanism in your design's lifespan.

- If your primary focus is chemical inertness: Teflon's stability is world-class, making it ideal for protecting equipment from corrosive substances in processing or storage.

- If your primary focus is environmental or electrical insulation: Its excellent weatherability and dielectric properties make it a reliable choice for protecting sensitive components.

By understanding that Teflon's key benefit is also the source of its primary limitation, you can deploy it with precision and reliability.

Summary Table:

| Key Property | Why It Matters for Application |

|---|---|

| Self-Lubricating Transfer Film | Creates low friction (Teflon-on-Teflon) but is a sacrificial process, dictating component lifespan. |

| Extreme Chemical Resistance | Ideal for corrosive environments in chemical processing, pharmaceuticals, and storage. |

| Excellent Weatherability | Withstands UV, moisture, and temperature extremes for outdoor and electrical components. |

| Inherent Wear Mechanism | Critical for design: high-load or high-cycle applications accelerate material loss. |

Need high-performance PTFE components that balance low friction with durability?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components. We understand the critical trade-offs between Teflon's self-lubricating properties and its wear characteristics. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can help you select the right material and design for your application's specific demands, from prototypes to high-volume production.

Contact our experts today to discuss how our custom PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What does PTFE stand for? The Science Behind the Super-Material

- What are the critical conditions for the polymerization step in PTFE manufacturing? Mastering Temperature, Pressure, and Initiator Control

- What is expanded PTFE and what are its key properties? A Guide to the Microporous Wonder Material

- How is PTFE used in the beauty industry? Enhance Product Performance and Safety

- What are the main applications of PTFE material? Unlock Superior Performance in Demanding Industries

- What are the benefits of molybdenum disulfide (MoS2)-filled PTFE? Enhance Durability & Performance

- Why does PTFE have hydrophobic properties? The Science Behind Its Water-Repellent Power

- What support is available for using PTFE laminated membrane filters? From Prototype to Production Success