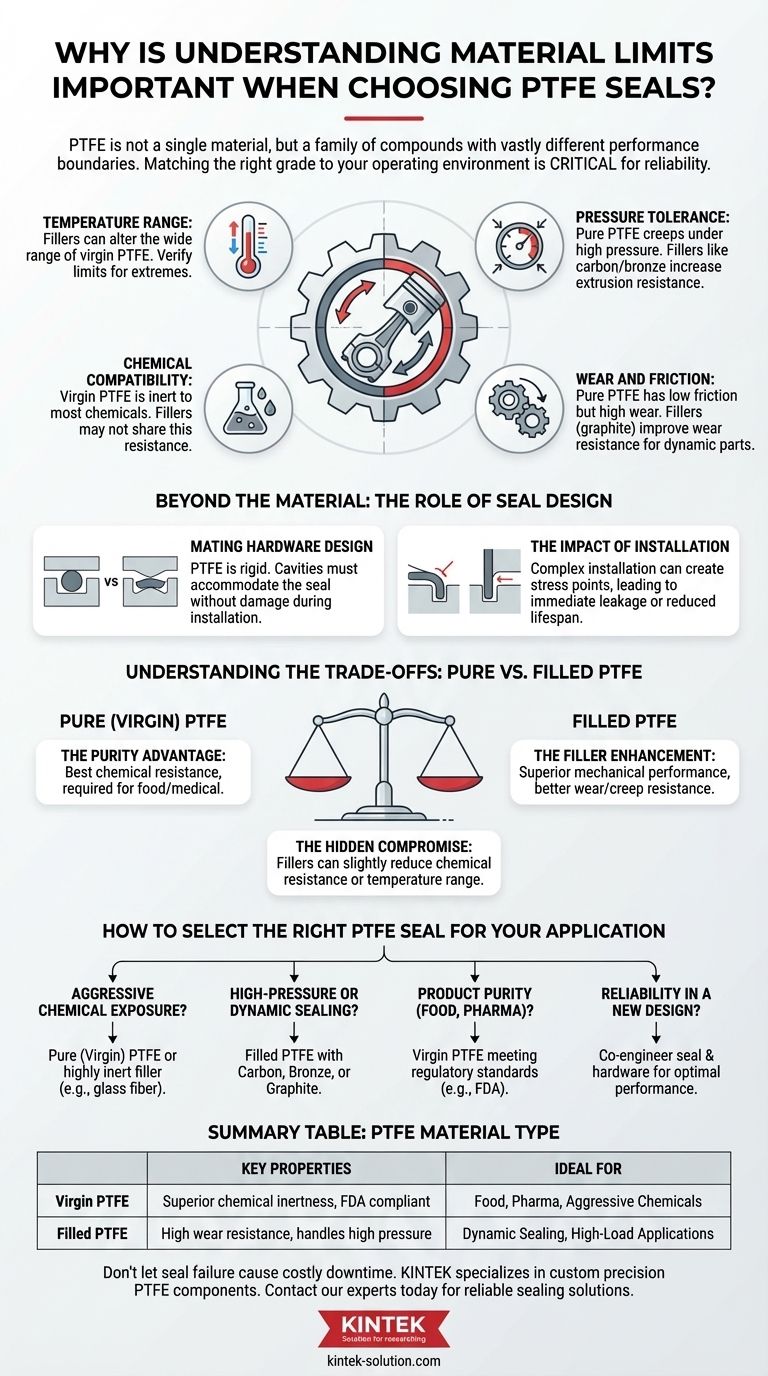

To put it simply, understanding the material limits of Polytetrafluoroethylene (PTFE) is critical because "PTFE" is not a single material. It is a family of materials, each with vastly different performance boundaries for temperature, pressure, and wear resistance. Selecting the wrong grade for your specific operating conditions is a direct path to premature seal failure, leakage, and costly downtime.

The core challenge is not merely choosing a PTFE seal, but precisely matching a specific PTFE compound and seal design to the complete operating environment. This alignment of material properties with application demands is the foundation of reliable and long-lasting sealing performance.

The Core Variables: What Defines a Seal's Limits?

A seal's success or failure is determined by its ability to withstand its environment. For PTFE, the performance profile is defined by a few key variables that can be modified with different fillers.

Temperature Range

Pure, or "virgin," PTFE has an impressively wide operating temperature range. However, fillers added to enhance other properties can sometimes alter this range. It is essential to verify the specific temperature limits of the exact compound you are considering for both high and low-temperature extremes.

Pressure Tolerance

While PTFE is durable, pure PTFE can be susceptible to deformation or "creep" under high pressure, especially when combined with high temperatures. Fillers like carbon, bronze, or stainless steel are added to significantly increase the seal's resistance to extrusion and maintain its shape under high loads.

Chemical Compatibility

One of PTFE's most famous properties is its extreme chemical inertness. Virgin PTFE is resistant to almost all industrial chemicals and solvents. This makes it an ideal choice for aggressive media, but care must be taken with filled grades, as the filler material itself may not share this level of resistance.

Wear and Friction

PTFE has an exceptionally low coefficient of friction, making it naturally self-lubricating. For dynamic applications involving sliding or rotating parts, this is a major advantage. However, pure PTFE can have a high wear rate. Fillers like graphite and carbon are often added to dramatically improve wear resistance and extend the seal's service life in moving applications.

Beyond the Material: The Role of Seal Design

The raw material is only half the equation. How that material is shaped and how it interacts with the surrounding hardware are just as critical to its performance.

Mating Hardware Design

PTFE is a relatively rigid plastic, not a soft elastomer. A seal cannot simply be forced into a poorly designed cavity. The pocket or groove it sits in must be designed to accommodate the seal without damaging it during installation, which often involves stretching or compressing it into place.

The Impact of Installation

Complex hardware designs that require a seal to be twisted or bent excessively for installation can create unseen stress points or damage. This damage leads to immediate leakage or a drastically shortened lifespan. A well-designed system simplifies installation and protects the seal's integrity from the start.

Understanding the Trade-offs: Pure vs. Filled PTFE

Choosing the right PTFE seal almost always involves a trade-off. Understanding this balance is key to making an informed decision.

The Purity Advantage

Pure (virgin) PTFE offers the absolute best chemical resistance and is often required for food-grade or medical applications. It is the benchmark for chemical inertness.

The Filler Enhancement

Filled PTFE grades are engineered for superior mechanical performance. They provide significantly better resistance to wear, creep, and deformation under load, making them essential for high-pressure and dynamic sealing.

The Hidden Compromise

The trade-off is that adding a filler can slightly reduce the material's chemical resistance or its usable temperature range. A bronze-filled seal, for example, gains tremendous compressive strength but would be unsuitable for use with strong acids that would attack the filler material.

How to Select the Right PTFE Seal for Your Application

Your final choice must be guided by your primary operational challenge.

- If your primary focus is aggressive chemical exposure: Prioritize pure (virgin) PTFE or a seal with a highly inert filler like glass fiber.

- If your primary focus is high-pressure or dynamic sealing: Select a filled PTFE with a material like carbon, bronze, or graphite to improve wear and creep resistance.

- If your primary focus is ensuring product purity (e.g., food, pharma): Always specify virgin PTFE that meets the required regulatory standards like FDA compliance.

- If your primary focus is reliability in a new design: Co-engineer the seal and the mating hardware with your supplier to ensure the design supports both easy installation and optimal performance.

Ultimately, treating the seal as an integral component of the system—not an afterthought—is the key to achieving long-term operational reliability.

Summary Table:

| PTFE Material Type | Key Properties | Ideal For |

|---|---|---|

| Virgin PTFE | Superior chemical inertness, FDA compliant | Food, Pharma, Aggressive Chemicals |

| Filled PTFE | High wear resistance, handles high pressure | Dynamic Sealing, High-Load Applications |

Don't let seal failure cause costly downtime. Selecting the correct PTFE compound is critical for reliability. KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware) for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your seals are perfectly matched to your operating environment. Contact our experts today to discuss your specific requirements and achieve long-lasting sealing performance.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How can PTFE be fabricated and what forms is it available in? Mastering Molding, Machining, and Coatings

- What precautions should be taken for maximum seal life expectancy? Follow the 75% Rule for Longevity

- What is a Teflon seal and what material is it made from? Unlock Superior Performance in Harsh Environments

- What are the characteristics of Modified PTFE with Premium Organic Fill? Superior Wear Resistance Without Abrasion

- What is the temperature range for welded PTFE bellow seals? Unlock Extreme Thermal Performance

- How can Teflon (PTFE) be processed into parts? A Guide to Compression Molding & CNC Machining

- How does bearing pressure affect the coefficient of friction in PTFE slide bearings? Maximize Performance with Higher Loads

- What are the primary applications of PTFE-lined ball valves? Control Corrosive & High-Purity Fluids