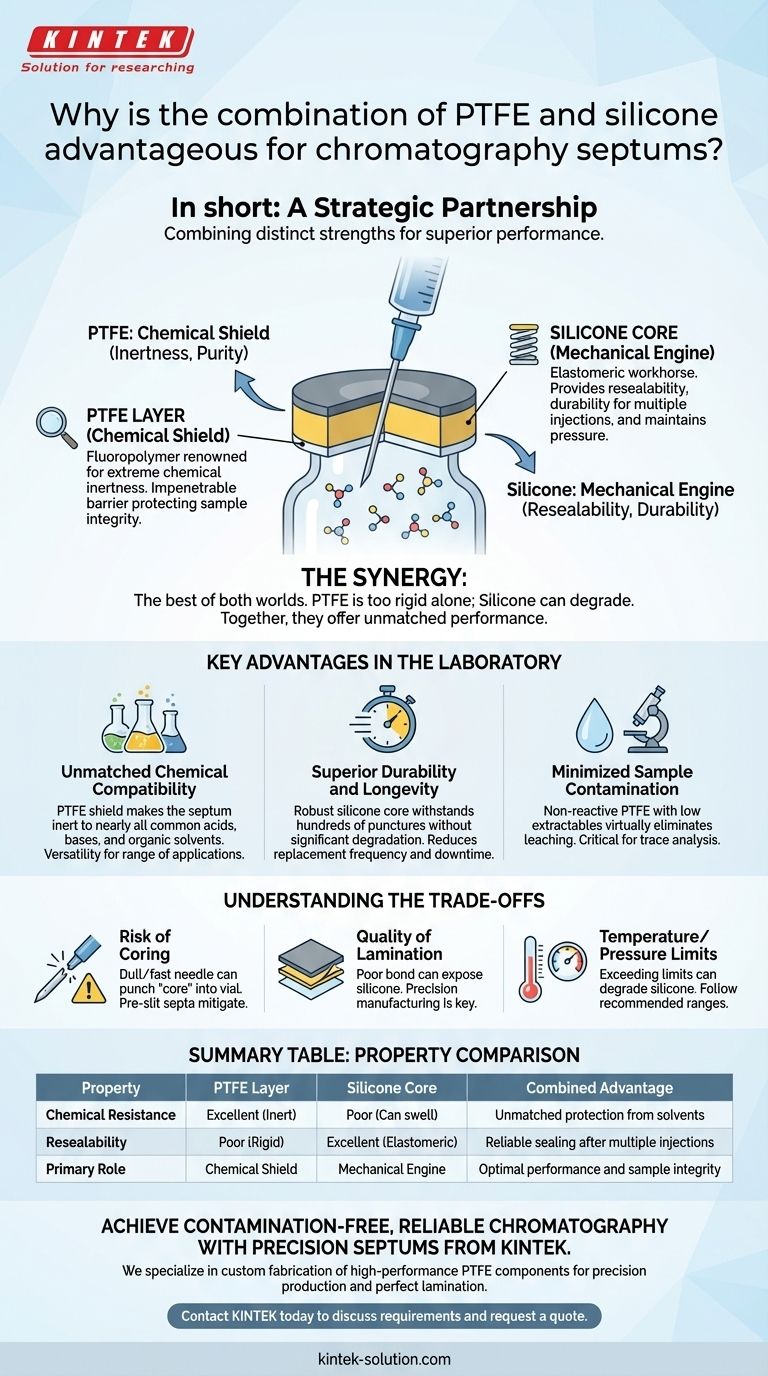

In short, combining PTFE and silicone creates a septum that leverages the distinct strengths of each material. The PTFE layer provides a chemically inert barrier to protect sample integrity, while the thicker silicone layer provides the physical resealability and durability required for repeated injections. This layered design offers the best of both worlds.

The core advantage is not a simple mixture, but a strategic partnership. PTFE acts as an impenetrable chemical shield facing the sample, while silicone provides the mechanical structure and self-sealing capability, creating a septum that is both robust and non-reactive.

The Anatomy of a High-Performance Septum

To understand the advantage, you must see the septum not as a single material, but as a two-part system designed for a specific purpose. Each material plays a critical, non-overlapping role.

The PTFE Layer: The Chemical Shield

Polytetrafluoroethylene (PTFE) is a fluoropolymer renowned for its extreme chemical inertness.

In a septum, a very thin layer of PTFE faces inward, toward the sample and solvent inside the vial.

This layer acts as a complete barrier, preventing any interaction between your sample and the main body of the septum. This is crucial for maintaining sample purity and ensuring reproducible results.

The Silicone Core: The Mechanical Engine

Silicone is the workhorse of the septum, forming its main structural body. Its key property is its elastomeric nature.

When a needle pierces the septum, the silicone yields easily and then re-seals tightly after the needle is withdrawn. This resealing is essential for maintaining pressure and preventing evaporation.

The durability of the silicone core allows for multiple injections without failure, a critical feature in high-throughput automated laboratories.

The Synergy: How the Layers Work Together

The combination is far superior to either material used alone.

Silicone by itself can swell or degrade when exposed to certain organic solvents. PTFE alone is too rigid and would not reseal properly after being punctured.

By laminating a thin PTFE film onto a thick silicone core, you get the chemical resistance of PTFE with the physical durability and resealability of silicone. The sample only ever touches the inert PTFE.

Key Advantages in the Laboratory

This intelligent design translates directly into more reliable and efficient analytical work.

Unmatched Chemical Compatibility

The PTFE shield makes the septum inert to nearly all common acids, bases, and organic solvents used in chromatography. This versatility allows a single type of septum to be used for a vast range of applications.

Superior Durability and Longevity

The robust silicone core can withstand hundreds of punctures without significant degradation. This reduces the frequency of septum replacement, which minimizes instrument downtime and lowers operational costs.

Minimized Sample Contamination

Because the PTFE layer is extremely non-reactive and has low extractables, the risk of the septum leaching contaminants into your sample is virtually eliminated. This is paramount in trace analysis, where even minor contamination can skew results.

Understanding the Trade-offs

While this combination is the industry standard, it's important to be aware of potential failure points.

The Risk of Coring

If the needle is dull or inserted too quickly, it can punch out a small piece of the septum material (a "core") that falls into the vial, contaminating the sample. Pre-slit septa are designed to mitigate this specific problem.

Quality of Lamination

The bond between the PTFE and silicone layers is critical. Poorly manufactured septa can delaminate, compromising the seal and exposing the sample to the less-resistant silicone underneath.

Temperature and Pressure Limits

While highly stable, these septa still have operational limits. Exceeding the recommended temperature range can cause the silicone to degrade, leading to a loss of sealing integrity and potential contamination from breakdown products.

Making the Right Choice for Your Analysis

Understanding this material science empowers you to select the best septum for your specific analytical goal.

- If your primary focus is trace analysis: Prioritize septa with a high-quality PTFE barrier to guarantee the lowest possible risk of contamination and analyte adsorption.

- If your primary focus is high-throughput screening: The durability and resealing capacity of the silicone core are most critical to prevent failures during long automated sequences.

- If your primary focus is working with aggressive solvents: The chemical inertness of the PTFE layer is non-negotiable to prevent septum degradation and ensure consistent results.

Choosing the correct vial septum is a foundational step toward achieving clean, accurate, and reproducible chromatographic data.

Summary Table:

| Property | PTFE Layer | Silicone Core | Combined Advantage |

|---|---|---|---|

| Chemical Resistance | Excellent (Inert) | Poor (Can swell) | Unmatched protection from solvents |

| Resealability | Poor (Rigid) | Excellent (Elastomeric) | Reliable sealing after multiple injections |

| Primary Role | Chemical Shield | Mechanical Engine | Optimal performance and sample integrity |

Achieve contamination-free, reliable chromatography with precision septums from KINTEK.

As detailed in this article, the strategic combination of PTFE and silicone is critical for protecting your samples and ensuring analytical integrity. KINTEK specializes in the custom fabrication of high-performance PTFE components, including chromatography septums, for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production to ensure the perfect lamination and performance of every septum, from prototypes to high-volume orders. Let us provide the components you need for clean, accurate, and reproducible data.

Contact KINTEK today to discuss your specific requirements and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application