In food processing, Teflon's heat resistance is critical because it ensures operational stability and food safety at extreme temperatures. Unlike other materials that can degrade, melt, or leach chemicals when heated, Teflon maintains its structural integrity and chemical inertness, which is essential for applications like industrial baking, frying, and heat sealing.

The core reason Teflon's heat resistance matters is that it's the bedrock property enabling all its other benefits. Its famous non-stick surface, chemical inertness, and mechanical reliability would be useless in food processing if they failed under the high heat required for cooking and manufacturing.

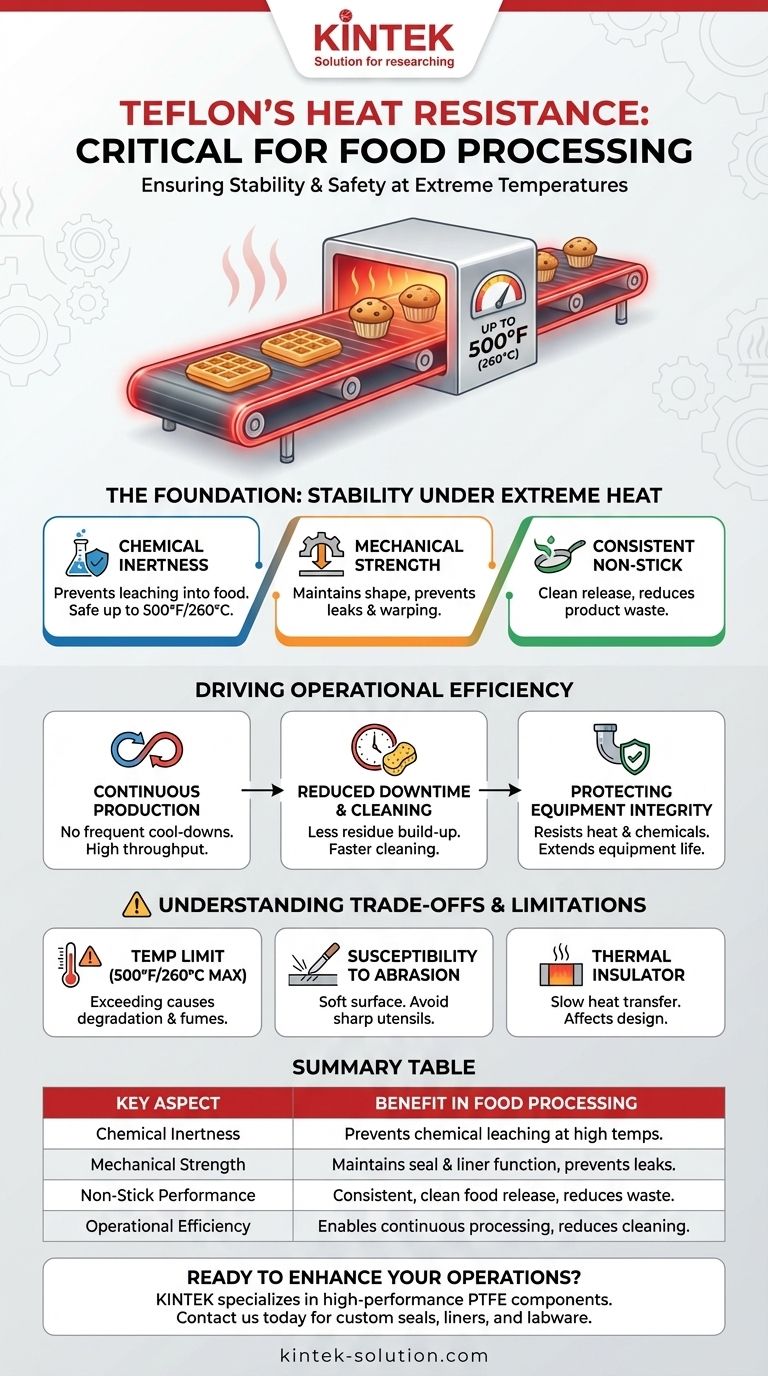

The Foundation: Stability Under Extreme Heat

Teflon (PTFE) doesn't just "survive" heat; it maintains its most critical characteristics. This stability is the primary reason it has become indispensable in demanding food-grade applications.

Maintaining Chemical Inertness

Many materials can become reactive when exposed to heat, potentially releasing harmful substances. Teflon is chemically inert to nearly all acids, solvents, and bases.

Crucially, it maintains this inertness up to 500°F (260°C), ensuring that no unwanted chemicals migrate from the equipment into the food during high-temperature cooking or processing.

Preserving Mechanical Strength

Heat can cause materials to warp, soften, or become brittle, leading to equipment failure. Teflon retains its mechanical properties and has very low thermal expansion.

This means components like gaskets, seals, and linings maintain their precise shape and function, preventing leaks and ensuring consistent performance in machinery.

Ensuring Consistent Non-Stick Performance

Teflon's release properties are its most well-known feature. This non-stick capability is a direct result of its stable surface chemistry.

Because that chemistry does not change with heat, food products from waffles to muffins release cleanly and reliably, batch after batch. This reduces product waste and maintains the intended texture and appearance.

How Thermal Stability Drives Operational Efficiency

The ability to perform reliably under heat translates directly into tangible benefits for productivity and cost savings on the production line.

Enabling Continuous Production

Equipment coated or made with Teflon can operate continuously at high temperatures without the need for frequent cool-down cycles.

This is vital for processes like conveyor baking or heat sealing, where consistent temperature is necessary for high throughput and uniform product quality.

Reducing Downtime and Cleaning

The combination of heat resistance and non-stick performance means less food residue builds up on machinery surfaces.

This significantly reduces the time and expense associated with equipment cleaning, minimizing downtime and maximizing plant efficiency.

Protecting Equipment Integrity

In applications involving hot and acidic food products (like tomato sauces) or caustic cleaning solutions, Teflon acts as a protective barrier.

By lining tanks, pipes, and valves, its ability to withstand both heat and chemicals prevents corrosion and extends the life of expensive processing equipment.

Understanding the Trade-offs and Limitations

While highly effective, Teflon's properties come with practical limitations that are crucial to understand for safe and effective implementation.

The Absolute Temperature Limit

The 500°F (260°C) service temperature is a firm ceiling. Exceeding this temperature can cause the polymer to degrade and release fumes.

Proper temperature control is therefore non-negotiable in any application to ensure both food safety and air quality in the plant.

Susceptibility to Abrasion

Teflon is a relatively soft material. While chemically robust, its surface can be damaged by sharp or abrasive materials.

Scratches or gouges can compromise the non-stick and sealing performance of the coating, requiring careful handling and the use of appropriate utensils or machinery components.

It Is a Thermal Insulator

Teflon does not conduct heat well. This is an advantage when used as a protective lining but a disadvantage in applications requiring rapid heat transfer through the material itself.

This property must be accounted for in equipment design, especially in molds or cooking surfaces where heating efficiency is a primary concern.

Making the Right Choice for Your Goal

Understanding these properties allows you to leverage Teflon effectively based on your specific operational priorities.

- If your primary focus is food safety: Teflon's key benefit is its profound chemical stability at high temperatures, which prevents harmful substances from migrating into your product.

- If your primary focus is operational efficiency: Its heat resistance allows for continuous, high-temperature processing and drastically reduces cleaning downtime, directly boosting throughput.

- If your primary focus is product quality: The material's consistent non-stick performance under heat ensures easy release, maintaining the intended shape and texture of delicate food items.

Ultimately, Teflon's heat resistance is the enabling property that guarantees food processing operations can be safe, efficient, and consistent.

Summary Table:

| Key Aspect | Benefit in Food Processing |

|---|---|

| Chemical Inertness | Prevents chemical leaching into food at high temperatures (up to 500°F/260°C). |

| Mechanical Strength | Maintains shape and function of seals and liners, preventing leaks. |

| Non-Stick Performance | Ensures consistent, clean food release, reducing waste and downtime. |

| Operational Efficiency | Enables continuous high-temperature processing and reduces cleaning cycles. |

Ready to enhance your food processing operations with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE (Teflon) seals, liners, and custom labware that deliver the critical heat resistance and chemical inertness your application demands. Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures your equipment operates safely and efficiently.

Contact us today to discuss your specific requirements and discover how our custom PTFE solutions can protect your product quality and boost your productivity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is ePTFE suitable for aerospace applications? Achieve Lightweight Reliability in Extreme Conditions

- How are Teflon bearings manufactured? A Guide to Machining, Molding, and Coating

- What are the key properties of PTFE? The Unique Strengths That Solve Extreme Engineering Challenges

- Why are PTFE lined valves preferred globally? Achieve Superior Corrosion Resistance & Cost Savings

- How do energized PTFE seals work? Achieve Reliable Sealing from Zero to High Pressure

- What are the differences between porous PTFE sheets and expanded PTFE membranes? Choose the Right Material for Your Application

- In which applications are anti-static PTFE bellows used? Essential for Static-Sensitive Industries

- What types of additives can be used with PTFE bushings? Enhance Performance for Demanding Applications