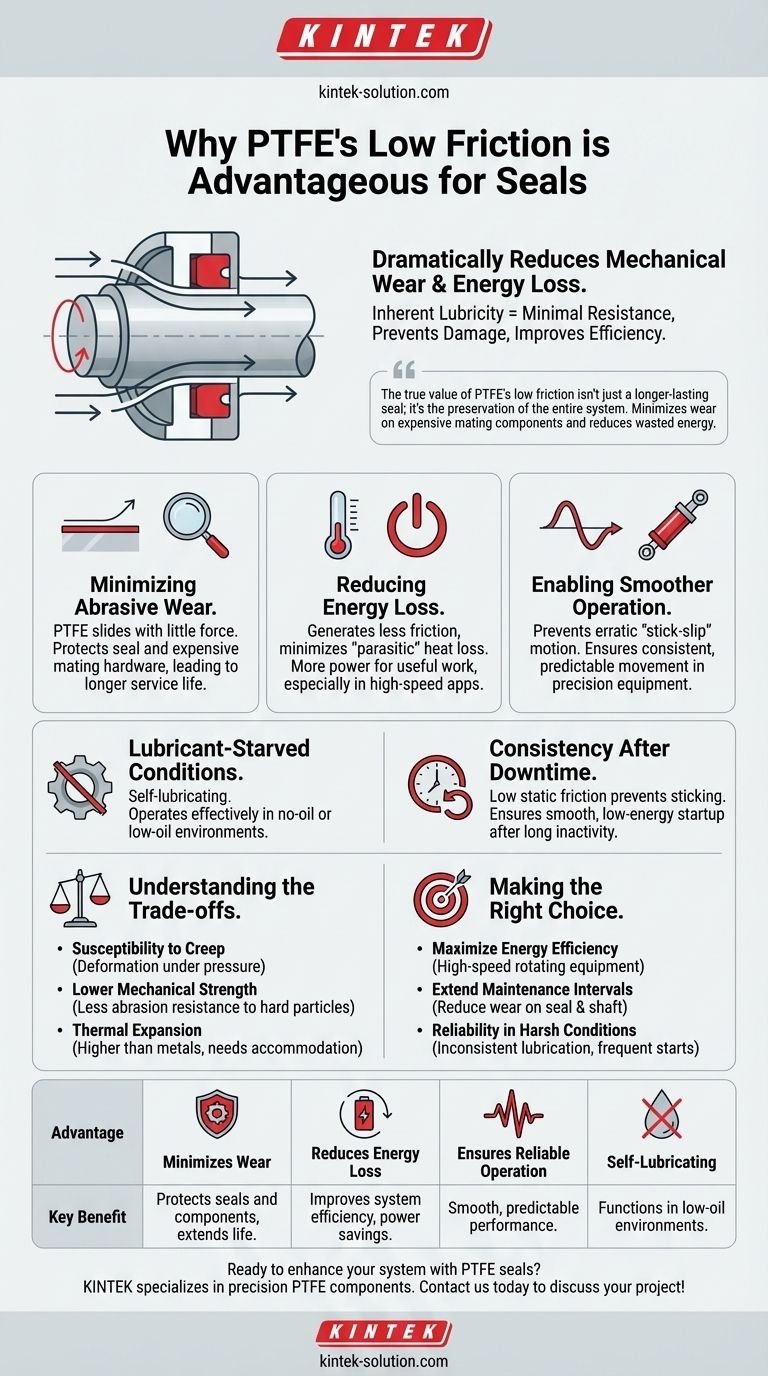

At its core, PTFE's low coefficient of friction is advantageous for seals because it dramatically reduces both mechanical wear and energy loss. This inherent lubricity means the seal and the component it touches (like a rotating shaft) rub against each other with minimal resistance, preventing damage and improving the overall efficiency of the machinery.

The true value of PTFE's low friction isn't just a longer-lasting seal; it's the preservation of the entire system. By minimizing wear on expensive mating components and reducing wasted energy, it lowers long-term operational and maintenance costs.

The Core Mechanisms of Low-Friction Sealing

To understand the full impact, we need to look beyond the seal itself and see how its low-friction property affects the entire mechanical system in which it operates.

Minimizing Abrasive Wear on Components

Friction is a force that physically grinds down surfaces over time. High-friction seals can slowly damage the shafts or rods they are sealing against, leading to costly repairs.

PTFE’s extremely low friction coefficient means it slides against mating surfaces with very little abrasive force. This protects not only the seal from premature failure but also the more critical and expensive hardware it contacts.

This quality directly translates to a longer service life for all related components.

Reducing Energy Loss and Heat Generation

In any dynamic system, friction converts motion into heat. This is wasted energy that reduces the machine's overall efficiency and can cause components to overheat.

Because PTFE seals generate significantly less friction, they minimize this "parasitic" energy loss. Less energy is wasted as heat, which means more power is available for useful work.

This is especially critical in high-speed applications, where the reduction in friction can lead to significant power savings and more stable operating temperatures.

Enabling Smoother, More Reliable Operation

High friction can cause erratic "stick-slip" motion, where a component sticks momentarily before jumping forward. This behavior is detrimental in precision equipment like hydraulic and pneumatic systems.

The consistent, low-friction nature of PTFE ensures smooth, predictable movement. This enhances the operational reliability and precision of the machinery.

Practical Advantages in Demanding Environments

The inherent lubricity of PTFE makes it uniquely suited for conditions where other materials might fail.

Performance in Lubricant-Starved Conditions

Many traditional seals rely on a constant film of oil or grease to reduce friction. If this lubrication fails or is not present, these seals can quickly degrade.

PTFE seals, however, are self-lubricating. They can operate effectively in no-oil or low-oil environments, making them ideal for systems where external lubrication is impractical or undesirable.

Consistency After System Downtime

Some sealing materials can adhere to a shaft after a prolonged shutdown. Upon restart, this can cause a high initial breakaway torque, potentially damaging the seal or the motor.

PTFE's low static coefficient of friction prevents this sticking effect, ensuring a smooth and low-energy startup even after long periods of inactivity.

Understanding the Trade-offs

No material is perfect, and objectivity requires acknowledging PTFE's limitations. While its low friction is a powerful advantage, its physical properties introduce design considerations.

Susceptibility to Creep

PTFE is a relatively soft material. Under high, constant pressure and temperature, it can slowly deform over time, a phenomenon known as "creep" or "cold flow." Seal design must account for this to ensure long-term sealing pressure is maintained.

Lower Mechanical Strength

Compared to elastomers or metal seals, PTFE has lower resistance to abrasion from hard particulate contamination. It excels at minimizing sliding friction but can be damaged by abrasive media within the system.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. This means it expands and contracts more with temperature changes. A well-designed PTFE seal assembly must accommodate this movement to remain effective across the intended operating temperature range.

Making the Right Choice for Your Goal

Selecting a seal material depends entirely on the primary objective for your application.

- If your primary focus is maximizing energy efficiency: Choose PTFE for high-speed rotating equipment to minimize power loss from frictional drag.

- If your primary focus is extending maintenance intervals: Use PTFE to dramatically reduce wear on both the seal and its expensive mating shaft, leading to a longer operational life.

- If your primary focus is reliability in harsh conditions: Rely on PTFE for systems with inconsistent lubrication or frequent start-stop cycles where other materials might stick or fail.

Ultimately, choosing a PTFE seal is an investment in the long-term health and efficiency of the entire mechanical system.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Minimizes Wear | Protects seals and mating components from abrasive damage, extending service life. |

| Reduces Energy Loss | Converts less motion into heat, improving overall system efficiency and power savings. |

| Ensures Reliable Operation | Prevents stick-slip motion for smooth, predictable performance in precision equipment. |

| Self-Lubricating | Functions effectively in no-oil or low-oil environments where other seals might fail. |

Ready to enhance your system's efficiency and reliability with high-performance PTFE seals?

At KINTEK, we specialize in precision manufacturing of PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your seals are designed to maximize performance, minimize long-term costs, and withstand demanding conditions.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific application needs.

Contact us today to discuss your project and discover the KINTEK advantage!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications