At its core, Polytetrafluoroethylene (PTFE) is etched to solve its most famous characteristic: its extremely low-friction, non-stick surface. While valuable for many applications, this property makes it nearly impossible to bond PTFE to other materials using conventional adhesives. The etching process is a chemical surface treatment that modifies this inert surface, making it receptive to bonding.

The central challenge with PTFE is its inherent inability to stick to anything. Etching is not a cleaning process; it is a fundamental chemical alteration of the PTFE surface, sacrificing some of its inertness on one side to gain the critical ability to bond with other substrates.

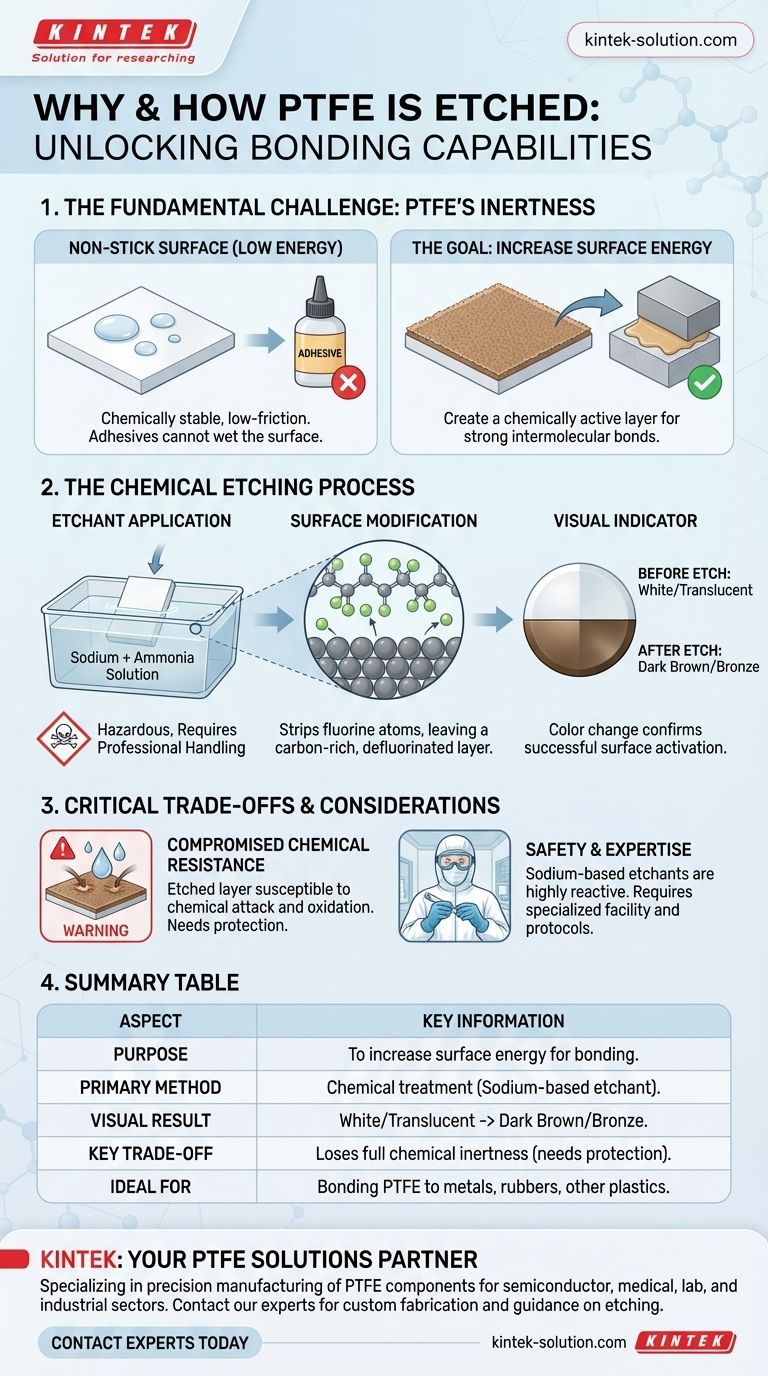

The Fundamental Challenge: PTFE's Inertness

Why PTFE Resists Bonding

PTFE is well-known for its incredibly low coefficient of friction and chemical inertness. This is due to its molecular structure, which creates a very stable, low-energy surface.

Adhesives work by wetting a surface and forming a strong intermolecular bond. Because PTFE's surface is so non-reactive and "slippery" at a molecular level, adhesives cannot properly wet the surface, leading to extremely weak or non-existent bonds.

The Goal of Etching

The sole purpose of etching PTFE is to increase its surface energy. This creates a more chemically active, or "bondable," surface layer.

This modification allows adhesives and other polymers to form strong, reliable bonds, enabling the creation of composite parts that leverage PTFE's benefits alongside the properties of other materials.

The Chemical Etching Process Explained

How Etching Modifies the Surface

The most common method for etching PTFE involves a potent chemical agent, typically a mixture of sodium and ammonia. This solution acts as a powerful reducing agent.

This chemical etchant physically strips fluorine atoms from the PTFE polymer chains on the surface. This leaves behind a carbon-rich, defluorinated layer that is chemically active.

The Visual Indicator of a Successful Etch

A properly etched PTFE surface is easy to identify. The material's original white or translucent appearance changes to a dark brown or bronze color.

This color change is a direct result of the carbonaceous layer created by the chemical reaction and serves as a clear visual confirmation that the surface is now ready for bonding.

Understanding the Trade-offs

Compromised Chemical Resistance

It is critical to understand that the etched surface is no longer pure PTFE. This new layer does not possess the same exceptional chemical resistance as the untreated material.

The etched side becomes susceptible to attack by certain chemicals and oxidation over time. Therefore, in applications requiring full chemical inertness, the etched surface must be completely covered and protected by the bonding agent or substrate.

Handling and Safety

The sodium-based etchants used in this process are highly reactive and hazardous. They require specialized handling procedures, a controlled environment, and proper personal protective equipment.

This is not a process typically performed outside of a professional manufacturing or laboratory setting due to the significant safety risks involved.

Making the Right Choice for Your Application

An understanding of this process is key to leveraging PTFE in complex assemblies. Your specific goal will determine whether etching is the correct approach.

- If your primary focus is creating a composite part: Etching is an essential step to reliably bond PTFE sheets, films, or components to metals, rubbers, or other plastics.

- If your primary focus is a standalone, non-stick surface: You do not need to etch PTFE; its natural properties are precisely what the application requires.

- If your primary focus is maximum chemical resistance: Do not use etched PTFE unless the etched surface can be perfectly sealed and isolated from the chemical environment.

Ultimately, etching is the essential bridge that allows the unique benefits of PTFE to be integrated into a wider world of engineered materials.

Summary Table:

| Aspect | Key Information |

|---|---|

| Purpose of Etching | To increase surface energy, enabling strong bonds with adhesives and other materials. |

| Primary Method | Chemical treatment using a sodium-based etchant (e.g., sodium in ammonia). |

| Visual Result | Surface color changes from white/translucent to dark brown/bronze. |

| Key Trade-off | The etched surface loses its full chemical inertness and must be protected. |

| Ideal For | Creating composite parts by bonding PTFE to metals, rubbers, or other plastics. |

Need reliably bonded PTFE components for your application?

At KINTEK, we specialize in the precision manufacturing and custom fabrication of PTFE seals, liners, labware, and other critical components. Our expertise ensures that processes like etching are handled correctly to deliver parts that meet the exacting demands of the semiconductor, medical, laboratory, and industrial sectors.

We can guide you on whether etching is the right solution for your project and provide high-quality, custom-fabricated PTFE components—from prototypes to high-volume orders.

Contact our experts today to discuss how we can enhance your next project with precision PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries benefit from PTFE's non-stick properties? Boost Efficiency and Purity

- What is the high-temperature decomposition method for cleaning Teflon residue? A Guide to High-Risk, High-Efficacy Removal

- What are the key features of Teflon bushings? Unlock Maintenance-Free Performance

- How do PTFE gaskets handle friction in flange connections? Achieve Low-Stress Sealing for Delicate Flanges

- What standard surface finishes are available for PTFE balls? Tumbled vs. Machined for Optimal Performance

- Are fragments of PTFE harmful if they come loose during medical procedures? The Truth About PTFE Safety

- What are some common applications of PTFE Expansion Bellows? Solve Corrosion, Temperature, and Vibration Challenges

- What factors should be considered when selecting a PTFE lip seal? Optimize Your Sealing System for Reliability