At its core, PTFE is difficult to machine because it is fundamentally unstable under the forces of cutting. Unlike metals that shear cleanly, PTFE’s unique combination of softness, low strength, and an extremely high rate of thermal expansion causes it to deform, expand, and tear, making precision a significant challenge.

The central problem isn't PTFE's hardness, but its lack of rigidity and its dramatic reaction to heat. Successful machining is a delicate balancing act of controlling temperature, minimizing pressure, and using exceptionally sharp tools to slice the material without distorting it.

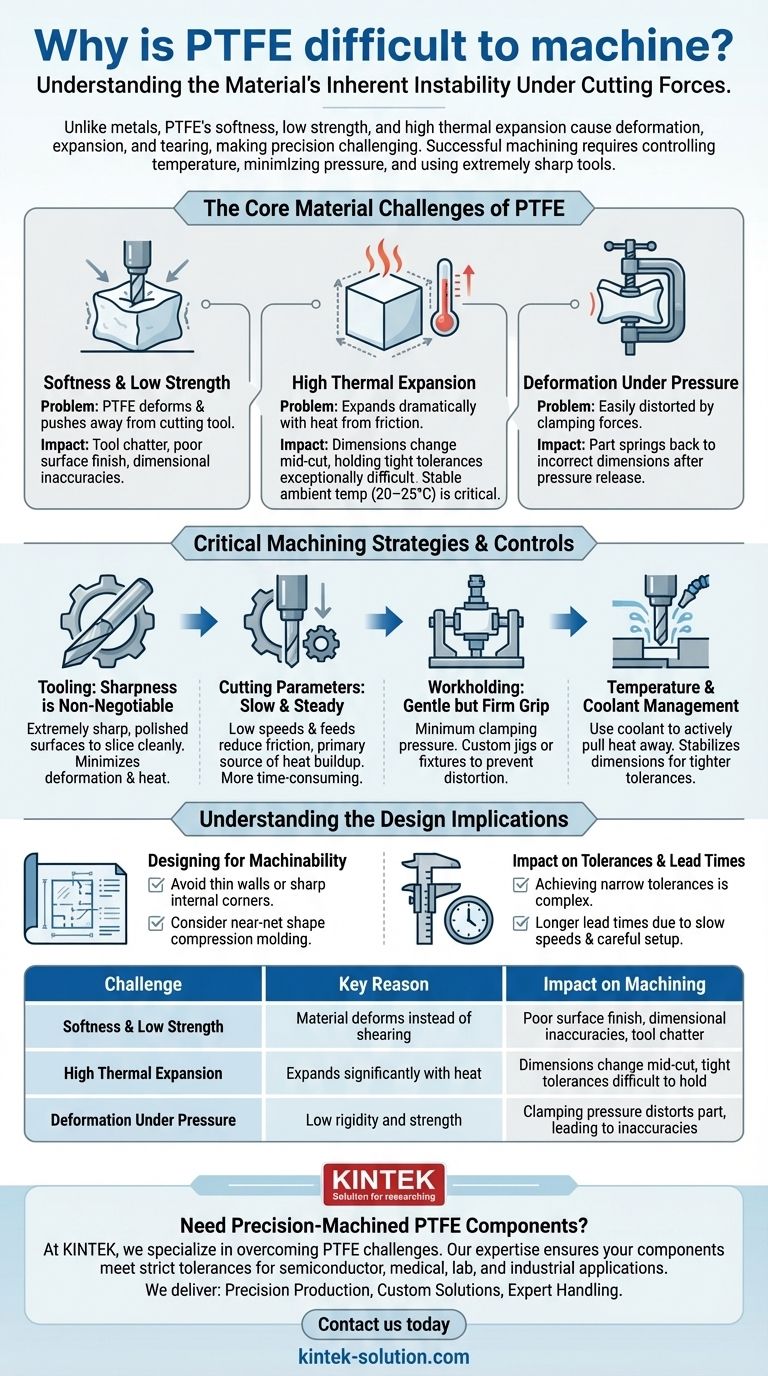

The Core Material Challenges of PTFE

To machine PTFE effectively, one must first understand the specific properties that make it so reactive to physical forces. These characteristics are inherent to the material and dictate every aspect of the machining process.

The Problem of Softness and Low Strength

PTFE is an incredibly soft material. When a cutting tool engages with it, the material has a tendency to push away and deform rather than shearing off into a clean chip.

This softness can also lead to tool chatter, where the tool vibrates against the workpiece, resulting in a poor surface finish and dimensional inaccuracies.

High Thermal Expansion

PTFE has one of the highest coefficients of thermal expansion among all plastics. This means it expands and contracts dramatically with even small changes in temperature.

The friction from the machining process generates heat, causing the material to expand mid-cut. This makes holding tight tolerances exceptionally difficult, as the part's dimensions are constantly changing.

Maintaining a stable ambient temperature, ideally between 20–25°C (68–77°F), is critical to minimize this variable.

Deformation Under Pressure

The material’s low strength means it can be easily distorted by external forces. Even the clamping pressure used to hold the part in a vise or chuck can be enough to squeeze it out of shape.

If the part is deformed while being held, it will be machined to the wrong dimensions. When the pressure is released, the part will spring back to its natural state, revealing the inaccuracy.

Critical Machining Strategies and Controls

Overcoming PTFE's challenges requires a process that prioritizes finesse over force. The right techniques are designed to minimize the introduction of heat and pressure.

Tooling: Sharpness is Non-Negotiable

Tools must be extremely sharp with highly polished surfaces. A sharp edge slices cleanly through the material, minimizing deformation and heat generation.

Carbide tooling is often preferred for its ability to hold a sharp edge for longer periods. The goal is to shear the material, not plow through it.

Cutting Parameters: Slow and Steady

Machinists must use low cutting speeds and feed rates. Moving the tool more slowly reduces friction, which is the primary source of heat buildup that causes thermal expansion.

This deliberate pace is a key reason why machining PTFE is a more time-consuming process compared to other materials.

Workholding: A Gentle but Firm Grip

Applying the minimum clamping pressure necessary is essential to prevent distorting the workpiece. Custom jigs or fixtures that support the part without squeezing it are often required for precision components.

For thin-walled or delicate parts, providing internal or external support during machining can prevent the walls from collapsing or deforming under tool pressure.

Temperature and Coolant Management

Using a coolant is highly recommended, not for lubrication, but to actively pull heat away from the workpiece and cutting tool. This helps stabilize the part's dimensions and allows for tighter tolerances.

Understanding the Design Implications

The inherent difficulties in machining PTFE have direct consequences that must be considered during the design phase of any component.

Designing for Machinability

Engineers must account for the material's properties. Features like extremely thin walls or sharp internal corners are prone to deformation and should be designed with care or avoided if possible.

Starting with a near-net shape from compression molding can reduce the amount of material that needs to be removed, minimizing machining time and the risk of error.

The Impact on Tolerances and Lead Times

Achieving and holding narrow tolerance ranges is a complex task. The combination of thermal expansion and deformation means that what is measured during the cut may not be the final dimension.

Because the process requires slow speeds, careful setup, and specialized handling, manufacturing custom PTFE parts often involves longer lead times compared to more stable engineering plastics.

Making the Right Choice for Your Application

Successfully using PTFE requires aligning your design goals with the realities of the manufacturing process.

- If your primary focus is high precision: You must prioritize strict environmental temperature control, the use of sharp tooling with coolants, and very slow machining speeds.

- If your primary focus is component stability: Design parts with robust features like thicker walls and generous radii, and ensure your tolerances account for thermal expansion.

- If your primary focus is minimizing cost and lead time: Consider if a different, more easily machined material could meet your requirements, or design the part to be molded as close to its final shape as possible.

Understanding these inherent material behaviors is the key to successfully transforming a block of PTFE into a functional, precision component.

Summary Table:

| Challenge | Key Reason | Impact on Machining |

|---|---|---|

| Softness & Low Strength | Material deforms instead of shearing | Poor surface finish, dimensional inaccuracies, tool chatter |

| High Thermal Expansion | Expands significantly with heat | Dimensions change mid-cut, tight tolerances difficult to hold |

| Deformation Under Pressure | Low rigidity and strength | Clamping pressure distorts part, leading to inaccuracies |

Need Precision-Machined PTFE Components?

At KINTEK, we specialize in overcoming the unique challenges of machining PTFE. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your components meet the strictest tolerances for semiconductor, medical, laboratory, and industrial applications.

We deliver:

- Precision Production: Using sharp tooling, controlled temperatures, and gentle workholding to minimize deformation.

- Custom Solutions: Tailored PTFE seals, liners, labware, and more to your exact specifications.

- Expert Handling: Managing thermal expansion and material stability for reliable, high-performance parts.

Let us handle the complexities of PTFE machining for you. Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications