At its core, Polytetrafluoroethylene (PTFE) is challenging to machine because its most valuable properties—softness, chemical inertness, and an extremely low coefficient of friction—directly interfere with the machining process. Unlike metals that shear cleanly, PTFE tends to deform, tear, and expand significantly with heat, requiring specialized tools, sharp cutting edges, and careful management of thermal effects to achieve precision.

The central challenge is that the physical forces of cutting easily overwhelm PTFE's structural integrity. The material deforms under clamping pressure, deflects away from the cutting tool, and expands dramatically with minimal heat, making it a constant battle to hold the workpiece steady and maintain dimensional accuracy.

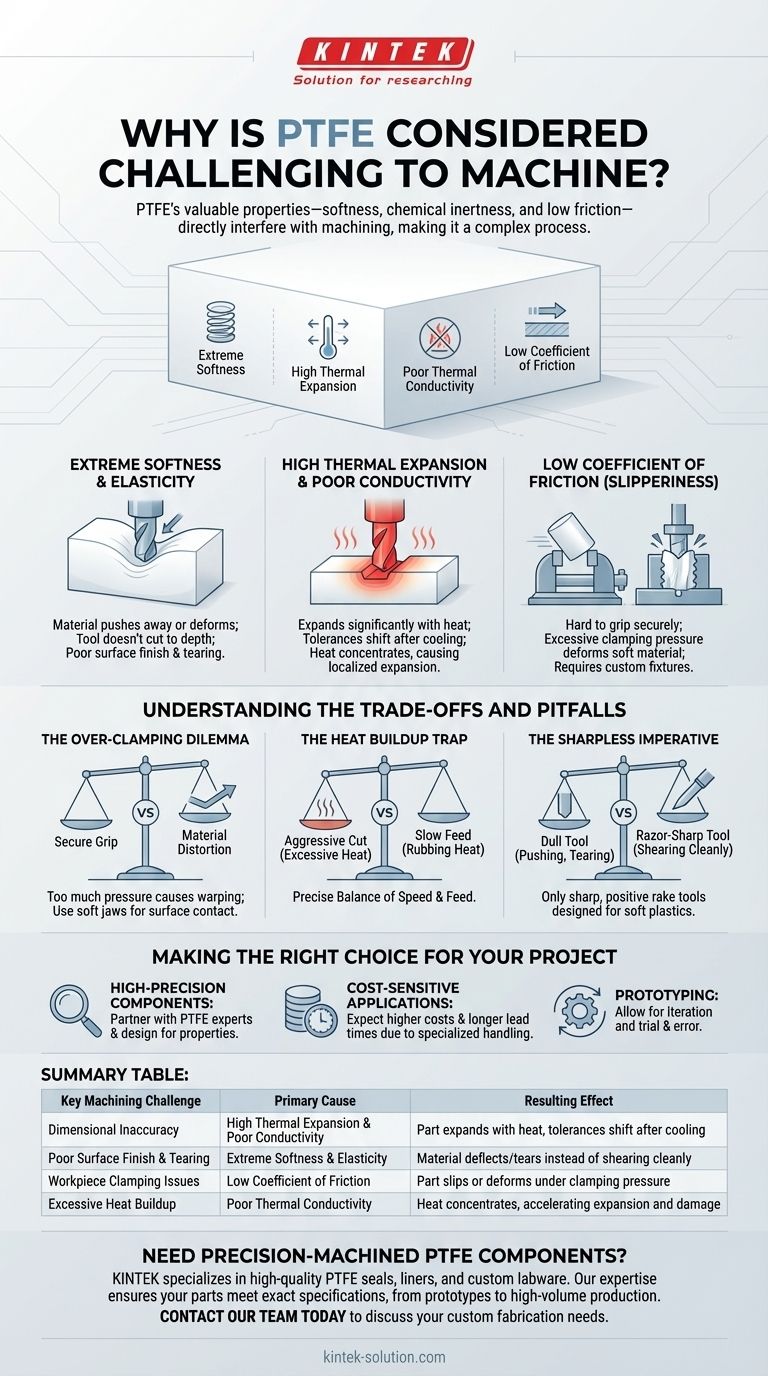

The Core Properties Driving Machining Difficulty

To understand the challenge, we must first look at the material's fundamental characteristics. The very reasons we choose PTFE for applications like seals and bushings are the same reasons it resists conventional machining techniques.

Extreme Softness and Elasticity

PTFE is an exceptionally soft material that lacks rigidity. When a cutting tool applies pressure, the material often pushes away or deforms elastically rather than shearing off cleanly.

This deflection means the tool may not cut to the intended depth, leading to dimensional inaccuracies. It also contributes to a poor surface finish, as the material is more likely to tear than be cut.

High Thermal Expansion

PTFE has a very high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. The friction from a cutting tool generates heat very quickly.

This localized heat causes the material to expand mid-cut, throwing off tolerances. A hole drilled to a precise diameter may shrink and become undersized once the part cools to ambient temperature.

Poor Thermal Conductivity

Compounding the expansion problem, PTFE is a thermal insulator. It does not dissipate heat well.

Heat generated at the cutting point becomes concentrated, leading to rapid, localized expansion. This makes managing the workpiece temperature a critical, and often difficult, part of the process.

Low Coefficient of Friction (Slipperiness)

PTFE's legendary slipperiness makes it difficult to grip securely in a vise or chuck without applying excessive force.

This creates a paradox: you need to hold the part firmly to prevent it from moving during the cut, but too much clamping pressure will easily crush or deform the soft material, ruining the final dimensions.

Understanding the Trade-offs and Pitfalls

Successfully machining PTFE requires navigating several key dilemmas where the wrong approach will guarantee a failed part. Understanding these trade-offs is crucial for both machinists and designers.

The Over-Clamping Dilemma

The most common mistake is applying too much clamping pressure to compensate for the material's slipperiness. This invariably leads to distortion, marring the surface or permanently warping the workpiece.

The solution often involves using custom fixtures or soft jaws that maximize surface contact area, allowing for a secure grip with minimal pressure.

The Heat Buildup Trap

An aggressive cut with a high feed rate generates excessive heat, causing the part to expand beyond its tolerance band. Conversely, a feed rate that is too slow can cause the tool to rub rather than cut, also generating significant heat and a poor surface finish.

Machinists must find a precise balance of high cutting speeds (spindle RPM) and controlled feed rates, often paired with a coolant, to get the tool in and out before significant heat can transfer to the part.

The Sharpness Imperative

A dull or improperly designed cutting tool is the fastest way to fail. A tool that is not razor-sharp will simply push and deform the PTFE, creating burrs, tearing the surface, and generating excessive heat.

Only tools with extremely sharp, positive rake cutting edges designed specifically for soft plastics should be used. This ensures the tool is shearing the material, not displacing it.

Making the Right Choice for Your Project

The difficulty of machining PTFE has direct implications for project timelines, costs, and design choices. Factoring these realities in from the start is essential for a successful outcome.

- If your primary focus is high-precision components: You must partner with a machine shop that has specific expertise in PTFE and use designs that account for the material's properties.

- If your primary focus is cost-sensitive applications: Be aware that the specialized handling, tooling, and slower cycle times required for PTFE will increase machining costs and lead times compared to other materials.

- If your primary focus is prototyping: Allow for iteration, as achieving the correct dimensions often requires trial and error to compensate for tool pressure and thermal expansion.

Ultimately, mastering PTFE machining comes from understanding and respecting the material's unique nature rather than fighting it.

Summary Table:

| Key Machining Challenge | Primary Cause | Resulting Effect |

|---|---|---|

| Dimensional Inaccuracy | High Thermal Expansion & Poor Conductivity | Part expands with heat, tolerances shift after cooling |

| Poor Surface Finish & Tearing | Extreme Softness & Elasticity | Material deflects/tears instead of shearing cleanly |

| Workpiece Clamping Issues | Low Coefficient of Friction | Part slips or deforms under clamping pressure |

| Excessive Heat Buildup | Poor Thermal Conductivity | Heat concentrates, accelerating expansion and damage |

Need precision-machined PTFE components? Don't let machining challenges compromise your project. KINTEK specializes in manufacturing high-quality PTFE seals, liners, and custom labware for the semiconductor, medical, and industrial sectors. Our expertise in managing PTFE's unique properties ensures your parts meet exact specifications, from prototypes to high-volume production. Contact our team today to discuss your custom fabrication needs and experience the KINTEK difference in precision and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry