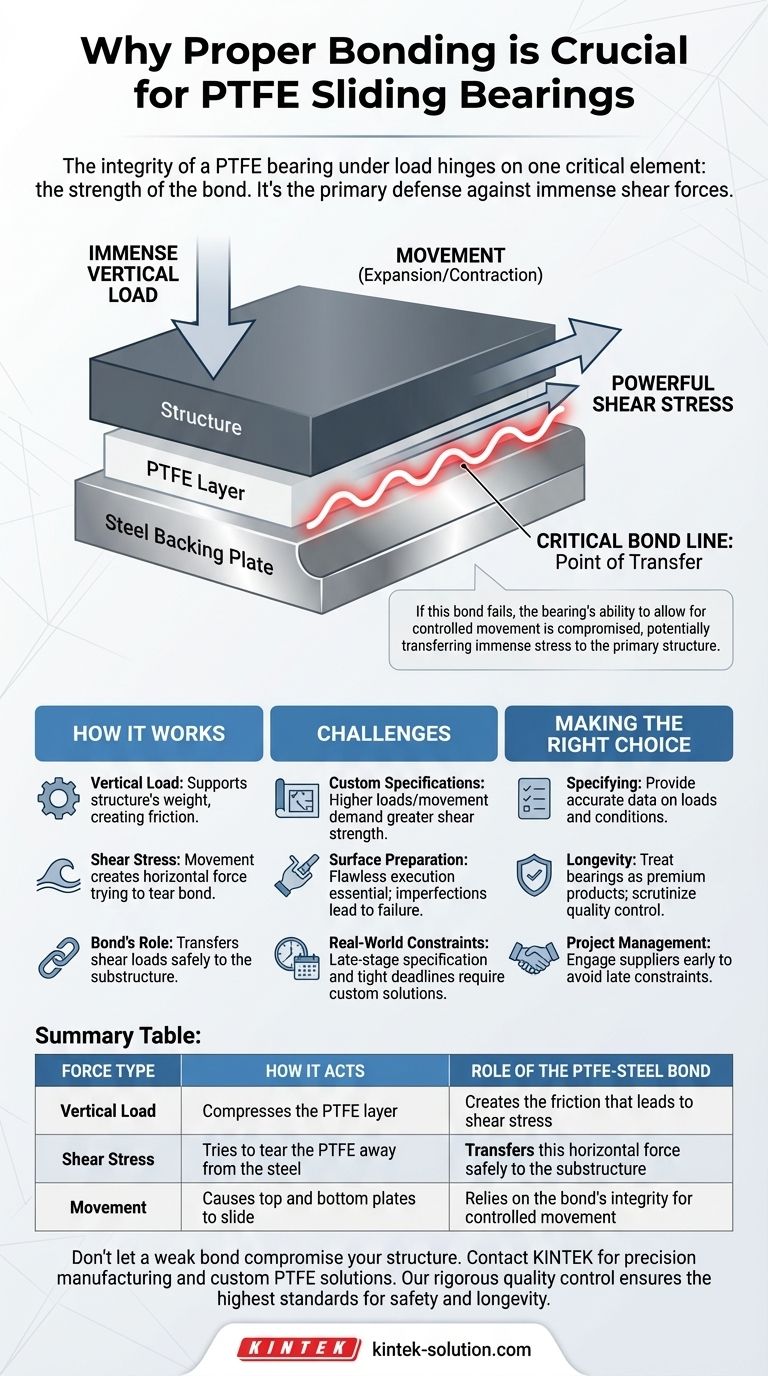

Proper bonding is crucial for PTFE sliding bearings because the immense vertical loads they support are converted directly into powerful shear forces at the bond line. If this bond between the PTFE and the steel backing plate fails, the bearing's ability to allow for controlled movement is completely compromised, potentially transferring immense stress to the primary structure.

The entire performance and safety of a PTFE sliding bearing under load hinges on one critical element: the strength of the bond. This connection is not a secondary feature; it is the primary defense against the shear forces generated by the structure's own weight and movement.

How a PTFE Bearing Manages Forces

To understand the bond's importance, we must first look at how these bearings work under real-world conditions. They are designed to support massive vertical weight while allowing for subtle horizontal movement.

The Role of Vertical Load

A PTFE sliding bearing's main job is to support a significant vertical load, such as the weight of a bridge deck or a heavy industrial vessel.

This downward force compresses the PTFE layer against its polished stainless steel counterpart.

The Emergence of Shear Stress

When the structure expands, contracts, or shifts, the top plate of the bearing moves relative to the bottom plate.

This movement, combined with the immense friction from the vertical load, creates a powerful horizontal force known as shear stress. This force acts directly along the bond line, trying to tear the PTFE layer away from its steel backing plate.

The Bond as the Point of Transfer

The adhesive bond is the single component responsible for transferring these shear loads from the PTFE layer to the steel substructure.

If the bond is weak or improperly applied, it becomes the bearing's most vulnerable point and the most likely point of failure.

Understanding the Trade-offs and Challenges

The reliability of a PTFE bearing is not guaranteed. It is the result of meticulous design and manufacturing, often in the face of significant project constraints.

The Impact of Custom Specifications

Every bearing is designed for a unique set of parameters, including specific vertical loads, anticipated movements (longitudinal and transverse), and potential uplift forces.

A higher vertical load or greater movement requirement places a proportionally greater demand on the bond's shear strength. This is why off-the-shelf solutions are rarely feasible for critical applications.

The Challenge of Surface Preparation

Achieving a durable bond requires an expert understanding of material science and flawless execution.

Careful and highly controlled surface preparation of both the steel plate and the PTFE is essential. Any contamination or imperfection in this process can create a weak point that will eventually fail under shear stress.

Real-World Project Constraints

Often, bearings are specified late in the design process, leading to challenges like limited space or restrictions on how the bearing can be attached to the structure.

These constraints require manufacturers to create highly customized solutions under tight deadlines, placing even more emphasis on the quality and reliability of the bonding process. Failure is not an option.

Making the Right Choice for Your Goal

Ensuring the integrity of a PTFE sliding bearing begins long before it arrives on site. It requires clear communication and an understanding of the critical role of the component.

- If your primary focus is specifying the bearing: Provide the manufacturer with the most accurate and comprehensive data possible regarding loads, movements, and environmental conditions. This is the foundation for a safe and effective design.

- If your primary focus is ensuring structural longevity: Treat the bearing as a premium, engineered product, not a commodity. Scrutinize the manufacturer's quality control processes, especially those related to surface preparation and bonding.

- If your primary focus is project management: Engage with bearing suppliers early in the design phase to avoid late-stage constraints that can compromise the ideal engineering solution.

Ultimately, recognizing the bond as the bearing's most critical component is key to safeguarding the long-term health and safety of your entire structure.

Summary Table:

| Force Type | How It Acts on the Bearing | Role of the PTFE-Steel Bond |

|---|---|---|

| Vertical Load | Compresses the PTFE layer | Creates the friction that leads to shear stress |

| Shear Stress | Tries to tear the PTFE away from the steel | Transfers this horizontal force safely to the substructure |

| Movement (Expansion/Contraction) | Causes top and bottom plates to slide | Relies on the bond's integrity to allow for controlled movement without failure |

Don't let a weak bond compromise your structure's integrity. The immense shear forces in PTFE sliding bearings demand a bond of absolute reliability. At KINTEK, we specialize in the precision manufacturing and custom fabrication of high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our rigorous quality control, especially in surface preparation and bonding processes, ensures your bearings meet the highest standards for safety and longevity. Contact our experts today to discuss your project's specific load, movement, and environmental requirements—from prototype to high-volume production, we deliver the precision you need.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems