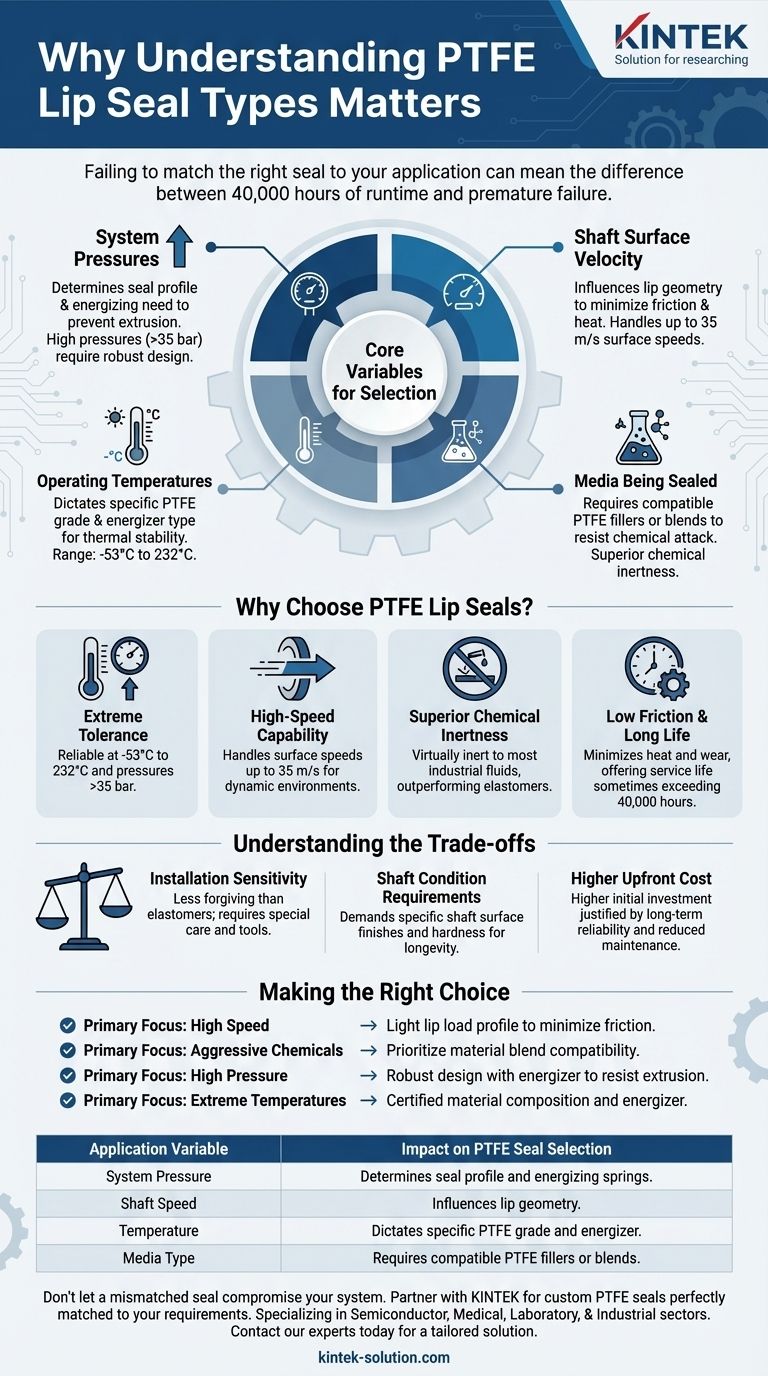

Failing to understand the different types of PTFE lip seals is the difference between a system that runs for 40,000 hours and one that fails prematurely. The importance lies in matching a specific seal design to the unique combination of speed, temperature, pressure, and media in your application. Selecting the right seal is not about finding the "best" one, but the one engineered precisely for your operational demands.

The core challenge is that PTFE's incredible versatility—its ability to handle extreme temperatures, high speeds, and aggressive chemicals—is only unlocked when the correct seal profile and material composition are chosen. A mismatch between the seal and the application environment leads to compromised performance and costly failures.

Why Choose PTFE Lip Seals in the First Place?

PTFE (Polytetrafluoroethylene) lip seals are specified when conventional elastomeric seals can no longer handle the operational demands. They are problem-solvers for the most challenging rotating applications.

Extreme Temperature and Pressure Tolerance

PTFE seals operate reliably across an exceptionally wide temperature range, typically from -53°C to 232°C (-65°F to 450°F).

They are also engineered to provide a tight seal at high pressures, often in excess of 35 bar (500 psi), where traditional seals might fail or extrude.

High-Speed Rotational Capability

These seals are designed for dynamic, high-speed environments. They can handle surface speeds of up to 35 m/s (10,000 sfpm), making them ideal for equipment like screw compressors, turbochargers, and racing components.

Superior Chemical Inertness

PTFE is virtually inert to most industrial fluids and chemicals. This makes PTFE lip seals the default choice for sealing aggressive or corrosive media that would quickly degrade standard rubber seals.

Low Friction and Long Life

The material's low coefficient of friction minimizes heat generation and wear, even in dry-running or abrasive media applications. This property contributes to an exceptionally long, maintenance-free service life, sometimes exceeding 40,000 hours.

Matching the Seal to the Application: The Core Variables

Understanding the types of PTFE seals means understanding the environmental factors that dictate their design. The selection process revolves around four critical variables.

System Pressures

The amount of pressure the seal must withstand directly influences its design. Higher pressures require specific seal profiles and potentially energizing springs to maintain consistent lip contact and prevent leaks without causing excessive wear.

Shaft Surface Velocity

High rotational speeds generate significant heat. The seal's lip geometry must be designed to minimize this frictional heat buildup, which can otherwise lead to premature wear and material degradation.

Operating Temperatures

While PTFE has a wide temperature range, extreme highs or lows dictate the specific grade of PTFE and the type of any energizing spring used in the seal assembly. The design must account for thermal expansion and contraction to maintain a consistent seal.

Media Being Sealed

The specific fluid or gas being sealed is paramount. While PTFE is broadly resistant, certain applications may require specific fillers or a custom material blend to ensure absolute compatibility and prevent any chemical degradation over the seal's lifespan.

Understanding the Trade-offs

While highly capable, PTFE seals are not a universal solution. An objective assessment requires acknowledging their specific requirements and limitations.

Installation Sensitivity

PTFE is a rigid material compared to elastomers. This makes the seals less forgiving during installation. Special care and proper tools are often required to avoid nicking or damaging the seal lip, which would compromise its performance.

Shaft Condition Requirements

To achieve optimal performance and longevity, PTFE lip seals often demand specific shaft surface finishes and hardness. An improperly prepared shaft can cause accelerated wear on the seal lip, negating its long-life benefits.

Higher Upfront Cost

Due to the advanced material and precision engineering involved, PTFE seals typically have a higher initial cost than standard elastomeric seals. This cost, however, is often justified by significantly longer maintenance intervals and greater reliability in extreme conditions.

Making the Right Choice for Your Goal

Selecting the correct PTFE lip seal is a process of prioritizing your application's most critical demand. Use the following guide to steer your decision-making.

- If your primary focus is high surface speed: Choose a seal profile with a lighter lip load, specifically designed to minimize friction and heat generation.

- If your primary focus is aggressive chemicals: Prioritize the specific PTFE material blend and its proven compatibility with the media above all other factors.

- If your primary focus is high pressure: You need a robust seal design, often with an energizer, that is engineered to resist extrusion and maintain constant sealing force.

- If your primary focus is extreme temperatures: Select a seal with a material composition and energizer (if applicable) certified for performance in your specific thermal range.

Mastering these variables ensures you select a seal that doesn't just work, but provides predictable, long-term reliability in your most critical systems.

Summary Table:

| Application Variable | Impact on PTFE Seal Selection |

|---|---|

| System Pressure | Determines seal profile and need for energizing springs to prevent extrusion. |

| Shaft Speed | Influences lip geometry to minimize friction and heat generation. |

| Temperature | Dictates specific PTFE grade and energizer type for thermal stability. |

| Media Type | Requires compatible PTFE fillers or blends to resist chemical attack. |

Don't let a mismatched seal compromise your system's performance. For over 40,000 hours of reliable operation in extreme conditions, partner with KINTEK. We specialize in custom PTFE seal fabrication—from prototypes to high-volume orders—for the semiconductor, medical, laboratory, and industrial sectors. Our precision engineering ensures your seals are perfectly matched to your specific speed, temperature, pressure, and media requirements. Contact our experts today for a solution tailored to your application's demands.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries