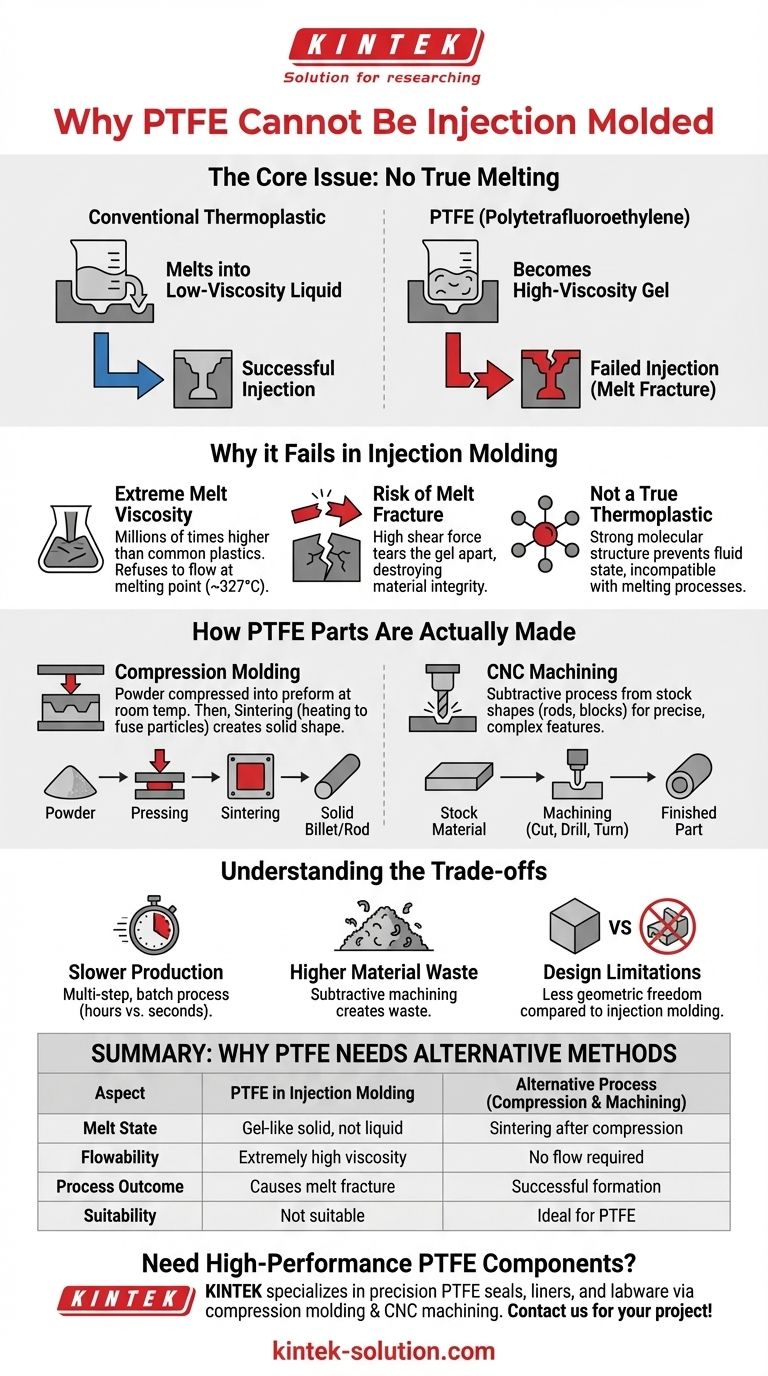

The short answer is that Polytetrafluoroethylene (PTFE) cannot be injection molded because it does not truly melt and flow like conventional thermoplastics. Its molecular structure gives it an extremely high melt viscosity, meaning even when heated past its melting point, it becomes a soft, gel-like solid rather than a liquid. This gel cannot be forced into a mold under pressure without its structure breaking down.

The core issue is a mismatch between the material and the process. Injection molding requires a material that becomes a low-viscosity liquid when heated, while PTFE is specifically engineered to maintain its structural integrity at extreme temperatures, preventing it from ever achieving a fluid state.

Why PTFE Fails in an Injection Molding Machine

Standard injection molding is a process of heating a plastic until it becomes a liquid, forcing it into a mold cavity under high pressure, and cooling it to solidify. PTFE’s unique properties disrupt every stage of this process.

The Problem of Extreme Melt Viscosity

Melt viscosity is a measure of a material's resistance to flow in its molten state.

PTFE has a melt viscosity that is exceptionally high—millions of times higher than common thermoplastics like polypropylene. When heated above its melting point of approximately 327°C (621°F), it does not become a liquid. Instead, it transitions into a translucent, highly viscous gel that stubbornly refuses to flow.

The Risk of Melt Fracture

Injection molding relies on immense pressure and shear force to push molten plastic into the mold.

Because PTFE exists as a fragile gel rather than a true liquid, these forces do not cause it to flow. Instead, the high shear stress literally tears the material apart on a molecular level. This phenomenon, known as melt rupture or melt fracture, destroys the material's integrity before it can ever take the shape of the mold.

PTFE is Not a True Thermoplastic

While often grouped with them, PTFE does not behave like a typical thermoplastic.

True thermoplastics can be repeatedly melted into a liquid and cooled into a solid without significant degradation. PTFE's molecular bonds are so strong that it resists this transition, making it fundamentally incompatible with any manufacturing process that requires a true molten state.

How PTFE Parts Are Actually Made

Since injection molding is not an option, specialized techniques are required to form PTFE into useful shapes. These methods are more akin to powder metallurgy than traditional plastics processing.

Compression Molding

This is the most common method for creating basic PTFE shapes like rods, sheets, and billets.

The process involves compressing PTFE resin powder into a mold at high pressure and room temperature to create a "preform." This preform is then removed and heated in a controlled oven in a process called sintering, which fuses the particles together into a solid mass.

CNC Machining

For creating precise, finished parts, CNC machining is the standard approach.

The basic shapes created through compression molding (like rods or blocks) are used as stock material. These are then machined—cut, drilled, turned, and milled—into the final, detailed components. This is why PTFE parts often have higher costs and longer lead times compared to injection-molded alternatives.

Understanding the Trade-offs

Choosing to use PTFE forces a different approach to manufacturing, which comes with significant consequences for production speed, cost, and design.

Slower Production Cycles

Injection molding is valued for its speed, often producing a finished part in seconds. Compression molding and sintering is a multi-step, batch process that takes hours. This makes high-volume production significantly slower and more labor-intensive.

Higher Material Waste

Machining is a subtractive process, meaning it creates the final part by cutting away material from a larger block. This waste material (swarf) adds to the overall cost of the finished component, whereas injection molding is a net-shape process with very little waste.

Design Limitations

The constraints of machining from stock shapes can limit the complexity of part geometry compared to the design freedom offered by injection molding. Features like intricate internal channels or extremely thin walls are much more difficult and costly to achieve.

Making the Right Choice for Your Goal

The inability to injection mold PTFE is not a flaw in the material, but a direct consequence of the properties that make it so valuable.

- If your primary focus is high-volume, low-cost production of complex parts: You must select a different material that is compatible with injection molding, such as PEEK or a fluoropolymer like FEP or PFA, if chemical and temperature resistance are still needed.

- If your primary focus is leveraging PTFE's unmatched chemical inertness and low friction: You must design for manufacturing via compression molding and subsequent CNC machining.

Understanding that PTFE does not melt but rather sinters is the key to selecting the correct manufacturing path for your application.

Summary Table:

| Aspect | PTFE in Injection Molding | Alternative Process |

|---|---|---|

| Melt State | Gel-like solid, not liquid | Sintering after compression |

| Flowability | Extremely high viscosity | No flow required |

| Process | Causes melt fracture | Compression molding + CNC machining |

| Suitability | Not suitable | Ideal for PTFE |

Need high-performance PTFE components? KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for semiconductor, medical, and industrial applications. Our expertise in compression molding and custom CNC machining ensures your parts meet exact specifications—from prototypes to high-volume orders. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application