Critically, deburring PTFE is not just about cleaning up an edge. It is a fundamental quality control step required to remove the sharp, raised edges and filaments created during machining. These defects, known as burrs, can prevent proper assembly, compromise sealing surfaces, and ultimately cause the premature failure of the component in its final application.

PTFE’s inherent softness and high thermal expansion cause it to deform and smear rather than chip cleanly during machining. Therefore, deburring isn't a cosmetic touch-up; it is an essential process that ensures the part's functional integrity, dimensional accuracy, and long-term reliability.

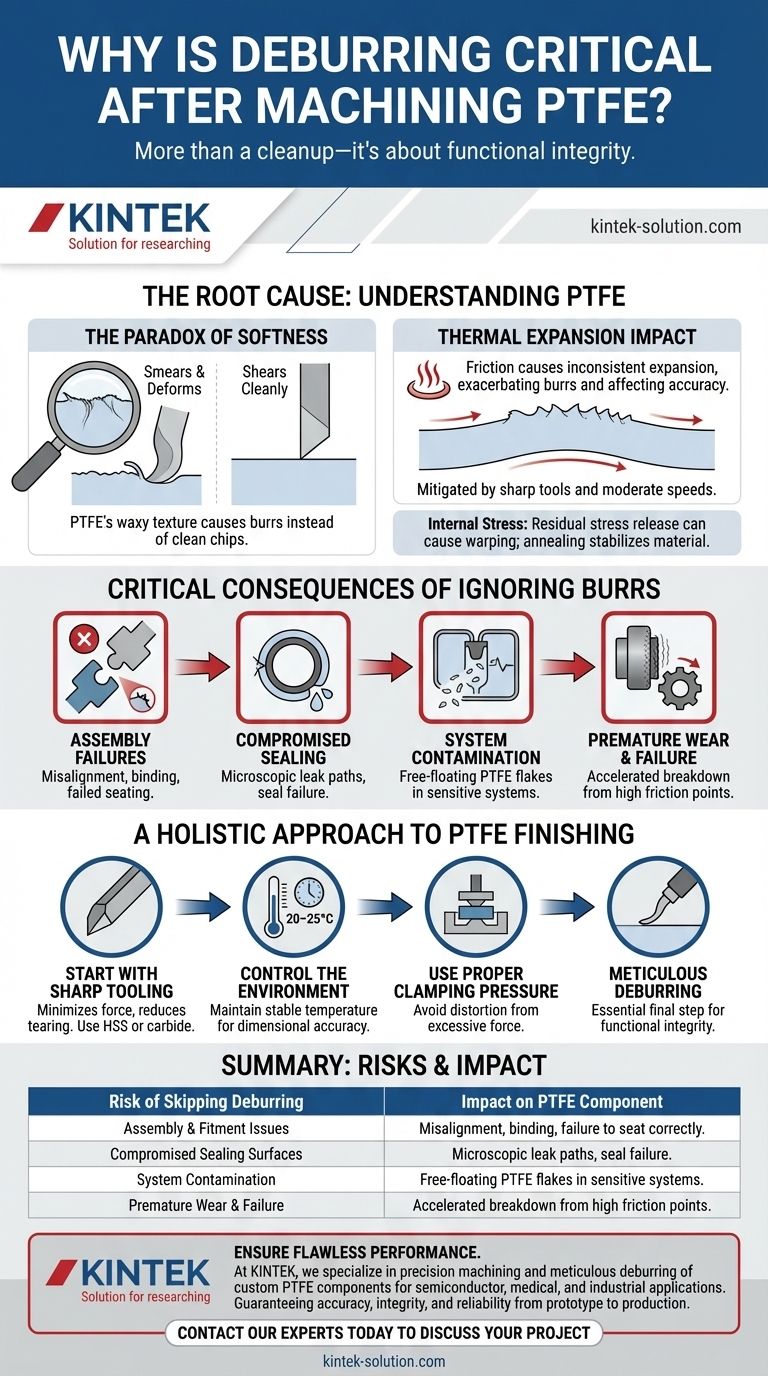

The Root Cause: Understanding PTFE's Behavior

To appreciate the importance of deburring, you must first understand the material itself. PTFE's unique properties make it both easy and challenging to machine.

The Paradox of Softness

PTFE has low strength and a soft, waxy texture. While this makes it easy to cut, it also means the material tends to tear or deform at the cutting edge instead of shearing away cleanly like a metal.

This "smearing" action is what creates the characteristic stringy or raised burrs on machined edges.

The Impact of Thermal Expansion

PTFE has a very high coefficient of thermal expansion. Heat generated from friction during the cutting process can cause the material to expand inconsistently.

This expansion can exacerbate burr formation and compromise dimensional accuracy, making post-machining finishing even more critical. Using moderate cutting speeds and extremely sharp tools helps mitigate this.

The Challenge of Internal Stress

Residual stresses from the manufacturing process can be locked within the PTFE material. Machining can release these stresses unevenly, leading to warping or cracking.

While not directly related to burrs, this is why annealing is often performed to stabilize the material before final machining, reducing the risk of failure later.

Critical Consequences of Ignoring Burrs

Failing to properly deburr a PTFE component can lead to significant and costly problems that undermine the very reason the material was chosen.

Assembly and Fitment Failures

Burrs can prevent components from seating correctly or fitting together as designed. This is especially problematic in assemblies with tight tolerances, where even a small burr can cause misalignment or binding.

Compromised Sealing Performance

In applications like gaskets, O-rings, or valve seats, the integrity of the sealing surface is paramount. A single burr can create a microscopic leak path, rendering the seal ineffective and causing system failure.

System Contamination

During operation, PTFE burrs can detach from the component. These free-floating flakes can contaminate sensitive systems, such as in medical devices, food processing equipment, or precision fluidics, where particulate matter is unacceptable.

Premature Wear and Failure

A raised burr can act as a point of high friction, snagging on mating surfaces. This can accelerate wear on both the PTFE part and the components it interacts with, leading to a rapid breakdown of the entire assembly.

A Holistic Approach to PTFE Finishing

Effective deburring doesn't happen in isolation. It is the final step in a series of best practices designed to manage PTFE's unique characteristics.

Start with Sharp Tooling

Prevention is the best strategy. Using extremely sharp and polished cutting tools, preferably High-Speed Steel (HSS) or carbide, minimizes the force needed to cut the material, reducing tearing and burr formation from the start.

Control the Environment

Maintaining a stable room temperature between 20–25°C (68–77°F) is crucial. This prevents the material from expanding or contracting during machining, which helps maintain dimensional accuracy and ensures a cleaner cut.

Use Proper Clamping Pressure

Because PTFE is soft, excessive clamping pressure can compress or deform the workpiece. This distortion can lead to inaccurate cuts and increase the likelihood of burrs. The part must be held securely but gently.

Making the Right Choice for Your Application

The level of deburring required depends entirely on the component's final function.

- If your primary focus is high-precision assembly: Deburring is non-negotiable to guarantee correct fit, prevent binding, and achieve specified tolerances.

- If your primary focus is fluid or gas sealing: Meticulous deburring is absolutely essential to eliminate potential leak paths and ensure the integrity of the sealing surface.

- If your primary focus is long-term reliability and safety: A holistic approach combining sharp tooling, proper environmental control, and thorough deburring is the only way to prevent part failure and system contamination.

Ultimately, deburring transforms a freshly machined piece of PTFE from a simple shape into a reliable, functional, and safe engineering component.

Summary Table:

| Risk of Skipping Deburring | Impact on PTFE Component |

|---|---|

| Assembly & Fitment Issues | Misalignment, binding, failure to seat correctly |

| Compromised Sealing Surfaces | Microscopic leak paths, seal failure |

| System Contamination | Free-floating PTFE flakes in sensitive systems |

| Premature Wear & Failure | Accelerated breakdown from high friction points |

Ensure your PTFE components perform flawlessly in their final application. At KINTEK, we specialize in precision machining and meticulous deburring of custom PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our process guarantees dimensional accuracy, functional integrity, and long-term reliability—from prototype to high-volume production. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the disadvantages of PTFE bushings? Key Limitations for Engineers

- Why can PTFE ball valves be used in corrosive media? Unmatched Chemical Resistance for Safe Fluid Control

- How do PTFE expansion joints contribute to sustainability? Enhance Long-Term System Integrity & Environmental Safety

- How is the bolt length determined for PTFE lined butterfly valves? Ensure a Safe, Leak-Proof Seal

- What are the key properties of PTFE sheets? Unlock Unmatched Chemical & Thermal Resistance

- What are the key roles of gland packing in industrial applications? Achieve Robust, Controllable Sealing

- Why are PTFE flange gaskets suitable for chemical processing industries? Unlock Superior Safety & Reliability

- What are the key considerations for selecting PTFE material for high performance butterfly valves? Ensure Long-Term Reliability