In short, PTFE sheets are used for lining acid tanks because of their exceptional, near-universal resistance to acids and other corrosive chemicals. This inertness makes PTFE an ideal barrier material, preventing aggressive substances from corroding the tank's structural metal.

The core reason for using PTFE is its unmatched chemical protection. However, its effectiveness is not inherent in the material alone; it is critically dependent on proper surface preparation, specialized installation, and understanding its physical limitations, especially under vacuum pressure.

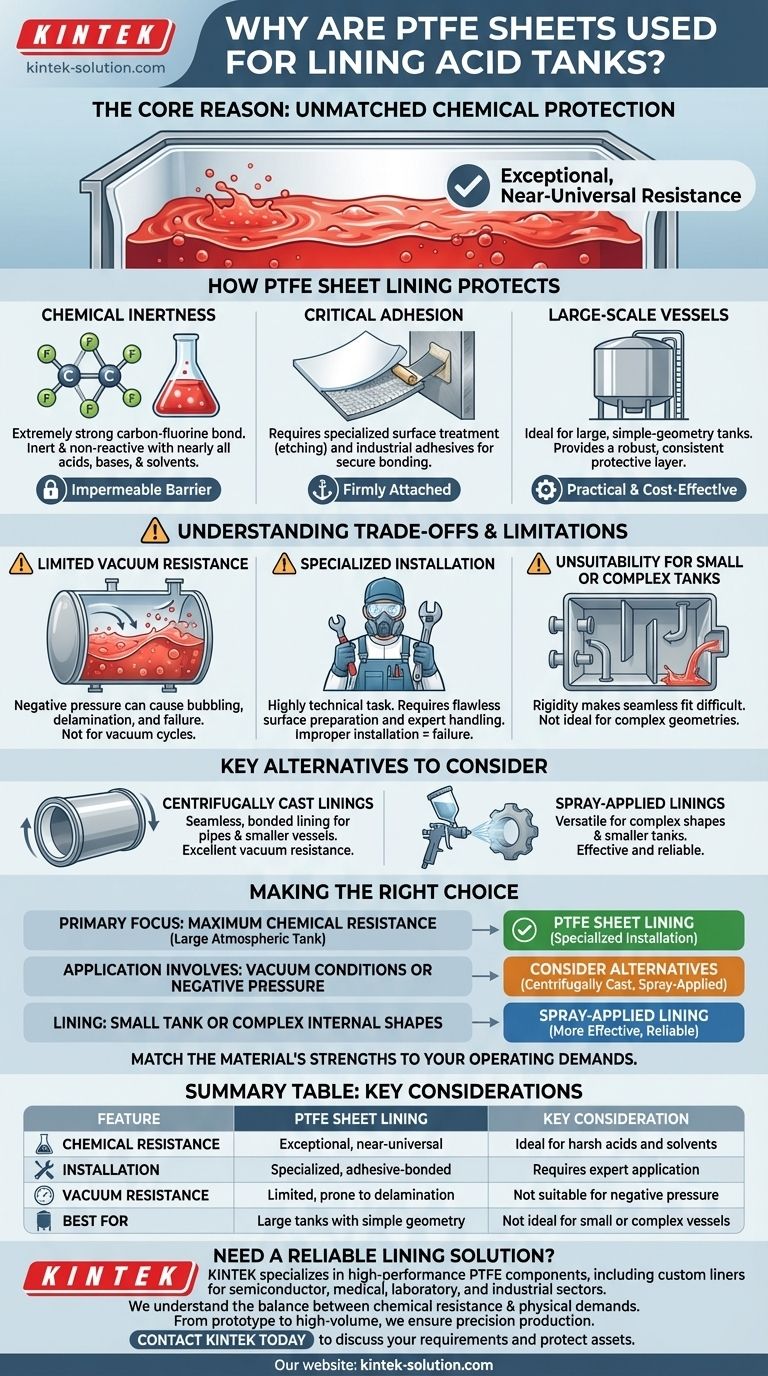

How PTFE Sheet Lining Protects Acid Tanks

PTFE sheet lining is a well-established method for protecting large-scale chemical processing and storage equipment. Its success relies on a combination of material science and expert application.

The Principle of Chemical Inertness

Polytetrafluoroethylene (PTFE) is a fluoropolymer with an extremely strong carbon-fluorine bond. This molecular structure makes it chemically inert and non-reactive with nearly all acids, bases, and solvents, even at high temperatures.

When used as a tank lining, the PTFE sheet acts as a completely impermeable barrier between the corrosive contents and the tank's metal shell.

The Critical Role of Adhesion

A PTFE sheet cannot protect a tank if it doesn't stay firmly attached to the interior wall. Since PTFE is famously non-stick, a specialized process is required.

The back of the lining sheet undergoes a surface treatment, typically a chemical etching process. This treatment alters the surface just enough to allow it to bond securely with specialized industrial adhesives. This ensures the lining remains fixed to the tank substrate.

Suitability for Large-Scale Vessels

The sheet lining method is particularly well-suited for large, simple-geometry tanks. It provides a robust, thick, and consistent protective layer across vast surfaces where other application methods might be less practical or cost-effective.

Understanding the Trade-offs and Limitations

While powerful, PTFE sheet lining is not a universal solution. Its physical properties introduce specific constraints that are critical to understand before selection.

Limited Vacuum Resistance

This is the most significant limitation of adhered PTFE sheet linings. Negative pressure (a vacuum) inside the tank can create a force that pulls the lining away from the tank wall.

This can cause bubbling, delamination, and eventual failure of the entire protective system. For applications involving vacuum cycles, other lining types are superior.

The Need for Specialized Installation

Applying a PTFE sheet lining is a highly technical task performed by specialized companies. It is not a simple adhesive application.

Success requires proper tank design, flawless surface preparation, and expert handling of the materials and adhesives. Improper installation is a primary cause of lining failure.

Unsuitability for Small or Complex Tanks

This method is not ideal for lining small tanks or vessels with complex internal geometries, such as nozzles, baffles, or tight corners.

The rigidity of the sheets makes it difficult to achieve a perfect, seamless fit in these areas.

Key Alternatives to Consider

When the limitations of PTFE sheet lining are a concern, two primary alternatives offer different advantages.

Centrifugally Cast Linings

In this process, a polymer is rotationally cast inside the vessel, creating a seamless, bonded lining. This method offers excellent vacuum resistance and is very effective but is typically limited to cylindrical shapes like pipes and smaller vessels.

Spray-Applied Linings

Fluoropolymer coatings can also be sprayed onto a tank's interior. This technique is highly versatile and ideal for coating equipment with complex shapes and for smaller tanks where sheet lining would be impractical.

Making the Right Choice for Your Application

Selecting the correct lining requires balancing chemical resistance needs with the physical and operational demands of the process.

- If your primary focus is maximum chemical resistance in a large atmospheric tank: PTFE sheet lining is an excellent, industry-standard choice, provided it is installed by specialists.

- If your application involves vacuum conditions or negative pressure: You must consider alternatives like centrifugally cast or specific spray-applied linings, as adhered PTFE sheets are prone to failure in these scenarios.

- If you are lining a small tank or one with complex internal shapes: A spray-applied lining will almost certainly provide a more effective and reliable long-term solution.

Ultimately, choosing the right protective lining is about matching the material's strengths to the specific demands of your operating environment.

Summary Table:

| Feature | PTFE Sheet Lining | Key Consideration |

|---|---|---|

| Chemical Resistance | Exceptional, near-universal | Ideal for harsh acids and solvents |

| Installation | Specialized, adhesive-bonded | Requires expert application |

| Vacuum Resistance | Limited, prone to delamination | Not suitable for negative pressure |

| Best For | Large tanks with simple geometry | Not ideal for small or complex vessels |

Need a reliable lining solution for your chemical process?

KINTEK specializes in manufacturing high-performance PTFE components, including custom liners for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between chemical resistance and physical demands.

Whether you need a standard PTFE sheet lining for an atmospheric tank or a custom solution for a challenging application, our team ensures precision production from prototype to high-volume orders.

Contact KINTEK today to discuss your specific requirements and protect your assets with confidence.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How do cooling and lubrication affect the CNC machining of PTFE? Master Thermal Control for Precision

- Are PTFE valves non-toxic, and why is this important? Ensure Product Purity and Safety

- What temperature range can PTFE sheets withstand? From -200°C to +260°C for Extreme Applications

- What are some household applications of Teflon in furniture? Protect Floors & Upholstery with Ease

- What are the benefits of the low friction and non-stick surface of PTFE gaskets? Enhance Equipment Life and Process Purity

- What materials are used to manufacture PTFE bars? A Guide to Virgin & Filled PTFE

- What are some examples of filled PTFE seals and their properties? Enhance Performance for Demanding Applications

- Why are PTFE oil seals considered a solution for 'forbidden sealing areas'? Conquer Extreme Environments