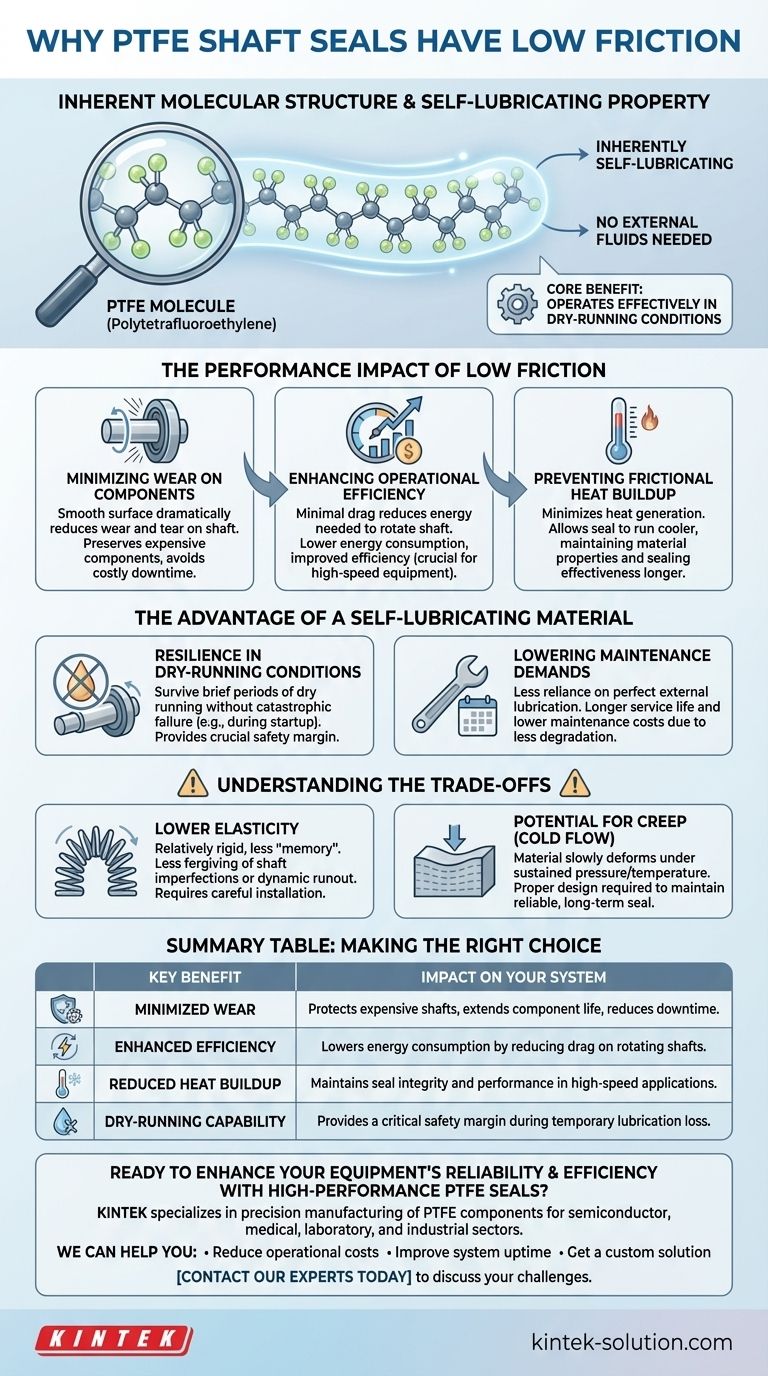

At its core, the exceptionally low friction of a PTFE shaft seal is a direct result of the inherent molecular structure of Polytetrafluoroethylene (PTFE). This material is intrinsically self-lubricating, meaning it does not depend on external fluids to achieve its smooth, low-drag performance. This characteristic allows it to operate effectively even in dry-running conditions where other materials would quickly fail.

The fundamental reason for PTFE's low friction is its inherent self-lubricating property. This single characteristic creates a cascade of benefits, primarily reducing wear, minimizing wasted energy, and significantly extending the operational life of both the seal and the shaft it protects.

The Performance Impact of Low Friction

The low coefficient of friction isn't just a technical specification; it translates directly into tangible performance advantages within a mechanical system. Understanding these benefits reveals why PTFE is a superior choice for many demanding applications.

Minimizing Wear on Critical Components

A primary function of any seal is to prevent leaks, but how it interacts with its mating surface is just as critical. High friction creates abrasive wear, degrading both the seal and the shaft.

PTFE's smooth surface dramatically reduces wear and tear on the shaft. This preserves the integrity of expensive components and avoids costly downtime for repairs or replacements.

Enhancing Operational Efficiency

In any dynamic system, friction is a source of energy loss. Overcoming this resistance requires additional power, which reduces the overall efficiency of the machinery.

Because PTFE seals create minimal drag, they reduce the energy needed to rotate the shaft. This leads to lower energy consumption and improved efficiency, a crucial factor in high-speed or continuously operating equipment.

Preventing Frictional Heat Buildup

Friction generates heat. In high-speed rotational applications, this heat can build up rapidly, potentially damaging the seal material, degrading lubricants, and affecting system performance.

PTFE's low friction minimizes the generation of heat, allowing the seal to run cooler and maintain its material properties and sealing effectiveness over a longer period.

The Advantage of a Self-Lubricating Material

While all seals benefit from system lubrication, PTFE's ability to function without it is a key differentiator that enhances system reliability.

Resilience in Dry-Running Conditions

Many seal failures occur during startup or in situations where lubrication is temporarily lost. Traditional elastomer seals can be destroyed in seconds under such conditions.

PTFE seals, being self-lubricating, can survive brief periods of dry running without catastrophic failure. This provides a crucial margin of safety for the entire system.

Lowering Maintenance Demands

The inherent lubricity of PTFE means less reliance on perfectly maintained external lubrication systems.

This quality leads to longer service life and lower maintenance costs because the seal is less susceptible to degradation from minor variations in lubrication.

Understanding the Trade-offs

No material is perfect for every application. To make an informed decision, it's essential to recognize the trade-offs associated with PTFE's unique properties.

Lower Elasticity

Compared to rubber or other elastomers, PTFE is a relatively rigid material. It has less "memory" and is not as flexible.

This means PTFE seals are less forgiving of imperfections on the shaft surface or significant dynamic runout. Installation also requires more care to avoid damaging the seal lip.

Potential for Creep (Cold Flow)

Under sustained pressure and temperature, PTFE can be subject to "cold flow," a phenomenon where the material slowly deforms over time.

Proper seal and gland design must account for this characteristic to ensure a reliable, long-term seal is maintained under constant load.

Making the Right Choice for Your Application

Your specific goal will determine if a PTFE seal is the optimal solution.

- If your primary focus is longevity and reduced maintenance: PTFE is an exceptional choice because its low-wear characteristics protect the shaft and extend service intervals.

- If your primary focus is energy efficiency: The minimal drag from a PTFE seal reduces parasitic energy loss, making it ideal for high-speed or energy-sensitive systems.

- If your application experiences potential dry-running: PTFE's self-lubricating nature provides a critical safety margin that can prevent catastrophic failure during temporary lubrication loss.

Ultimately, choosing a PTFE seal is an investment in long-term system reliability and operational efficiency.

Summary Table:

| Key Benefit | Impact on Your System |

|---|---|

| Minimized Wear | Protects expensive shafts, extends component life, and reduces downtime. |

| Enhanced Efficiency | Lowers energy consumption by reducing drag on rotating shafts. |

| Reduced Heat Buildup | Maintains seal integrity and performance in high-speed applications. |

| Dry-Running Capability | Provides a critical safety margin during temporary lubrication loss. |

Ready to enhance your equipment's reliability and efficiency with high-performance PTFE seals?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including seals, liners, and custom labware. Our expertise ensures you get a solution tailored to the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors.

We can help you:

- Reduce operational costs through lower energy consumption and extended maintenance intervals.

- Improve system uptime with seals designed to withstand challenging conditions.

- Get a custom solution for your unique application, from prototype to high-volume production.

Contact our experts today to discuss how our PTFE seals can solve your specific challenges.

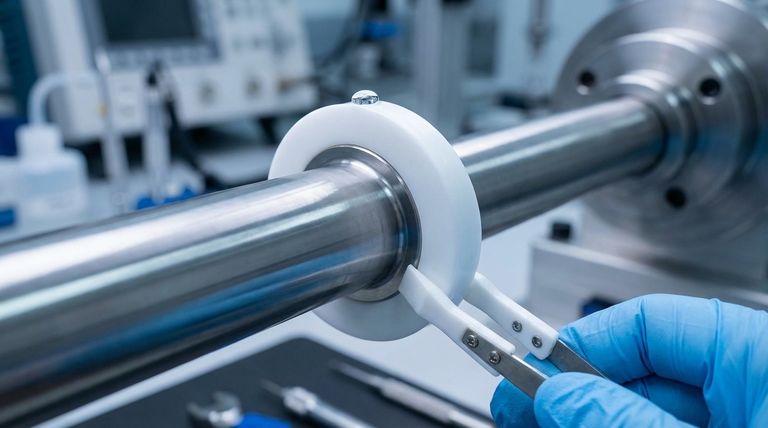

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability