In short, PTFE-coated O-rings are exceptionally suitable for food processing because their unique combination of properties directly solves the industry's most critical challenges: preventing contamination, simplifying cleaning, and ensuring material safety. Their non-stick surface, chemical inertness, and compliance with food-grade standards like FDA regulations make them a superior choice for hygienic environments.

The core reason PTFE excels is not just that it can withstand the food processing environment, but that its inherent properties—especially its non-stick nature—actively prevent the buildup of food particles and microorganisms, making sanitation simpler and more effective.

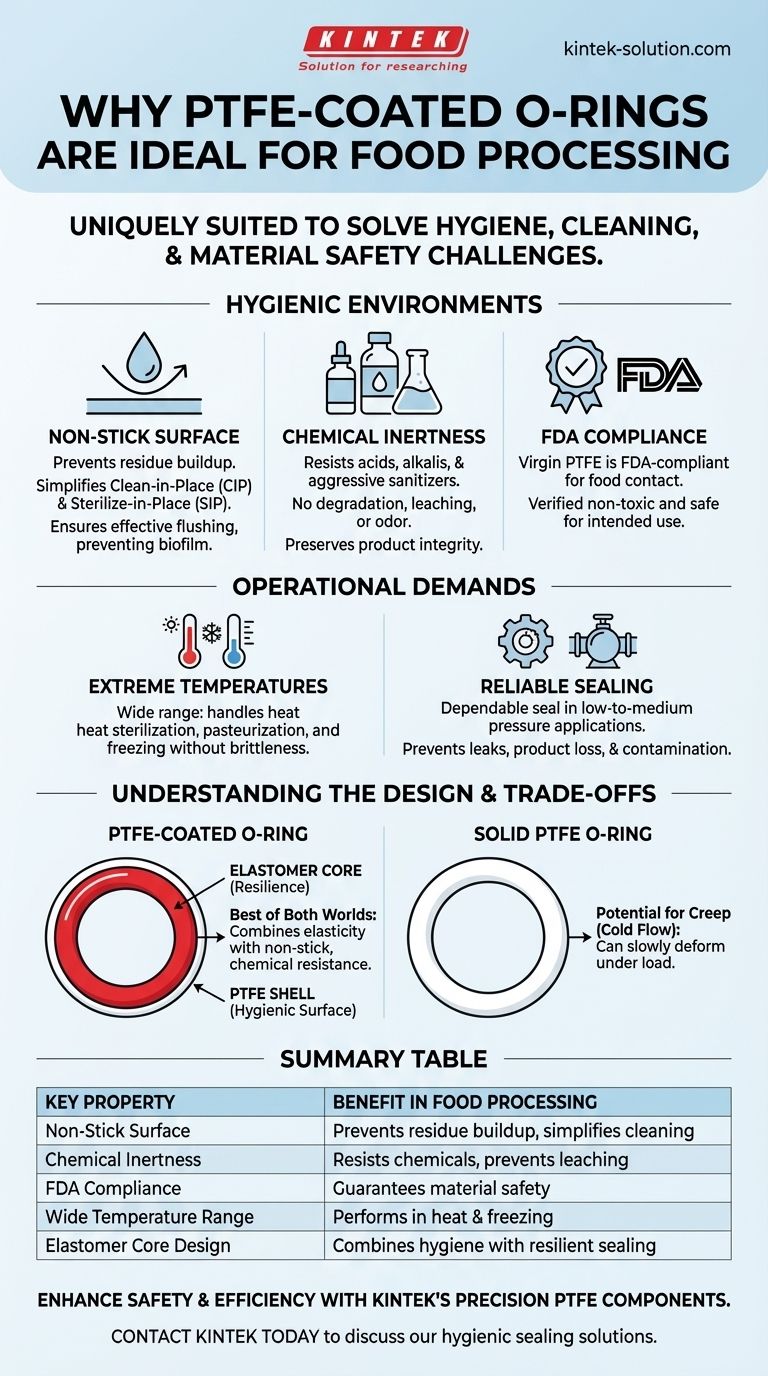

Why PTFE Excels in Hygienic Environments

The primary concern in any food processing application is hygiene. Contamination can ruin entire batches of product and pose a significant public health risk. PTFE's material properties provide a powerful defense against these risks.

Non-Stick Surface for Ultimate Cleanability

The most well-known property of PTFE is its extremely low friction, non-stick surface. In food processing, this means food materials, sugars, and oils are far less likely to adhere to the O-ring.

This characteristic is critical for Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems. It ensures that cleaning fluids can effectively flush away all residue, preventing the formation of biofilm where bacteria could thrive.

Chemical Inertness for Product Purity

PTFE is one of the most chemically inert polymers available. It does not react with acidic food products (like citrus or tomato), alkaline solutions, or the aggressive sanitizing agents used in daily washdowns.

This inertness guarantees that the seal will not degrade, leach chemicals, or impart any unwanted taste or odor to the food product, preserving its integrity and safety.

FDA Compliance and Material Safety

Materials used in food processing equipment must meet strict regulatory standards. Virgin PTFE is FDA-compliant for food contact applications.

This compliance provides a verified assurance that the material is non-toxic and safe for its intended use, simplifying the validation process for equipment manufacturers and food processors.

Meeting the Demands of Food Processing Operations

Beyond hygiene, seals in food processing must perform reliably under demanding physical conditions, including extreme temperatures and pressure changes.

Resilience to Extreme Temperatures

Food processing often involves cycles of intense heat and rapid cooling. PTFE has an exceptionally wide operating temperature range.

It maintains its integrity and sealing properties during cooking, pasteurization, and steam sterilization processes, as well as in freezing and cryogenic applications, without becoming brittle or degrading.

Reliable Sealing Performance

PTFE-coated O-rings provide a dependable seal in the low-to-medium pressure applications common in food and beverage systems.

They effectively seal equipment such as pumps, mixers, and valves that handle heated liquids and gases, preventing leaks that could lead to product loss and contamination.

Understanding the Trade-offs

While highly effective, it's important to understand the specific nature of PTFE seals to use them correctly. The distinction between a solid PTFE O-ring and a PTFE-coated O-ring is critical.

Elastomer Core with a PTFE Shell

A PTFE-coated O-ring typically consists of an elastomer core (like FKM or EPDM) encapsulated in a thin layer of PTFE.

This design combines the excellent elasticity and memory of the rubber core with the non-stick, chemical-resistant surface of PTFE. It provides the best of both worlds: a resilient seal with a hygienic surface.

Potential for Creep

Solid PTFE seals can be susceptible to creep, or "cold flow," where the material slowly deforms under a constant load.

Using a coated O-ring with an elastomeric core largely mitigates this issue, as the core provides continuous outward pressure to maintain the seal.

Making the Right Choice for Your Application

Selecting the right seal depends on balancing the demands of your specific process with the material's properties.

- If your primary focus is preventing product contamination: PTFE's non-stick and chemically inert surface provides the highest level of assurance against residue buildup and chemical leaching.

- If your primary focus is withstanding aggressive cleaning cycles: Its broad resistance to both high temperatures and harsh sanitizing chemicals makes it an incredibly durable choice for long-term use.

- If your primary focus is sealing a dynamic or high-flex application: A PTFE-coated O-ring with a suitable elastomer core is often the ideal solution, providing surface hygiene without sacrificing sealing flexibility.

By understanding these properties, you can confidently specify PTFE-coated seals to enhance the safety, efficiency, and reliability of your food processing equipment.

Summary Table:

| Key Property | Benefit in Food Processing |

|---|---|

| Non-Stick Surface | Prevents residue buildup, simplifies CIP/SIP cleaning |

| Chemical Inertness | Resists acids, alkalis, and sanitizers; prevents leaching |

| FDA Compliance | Guarantees material safety for food contact |

| Wide Temperature Range | Performs in heat sterilization and freezing applications |

| Elastomer Core Design | Combines surface hygiene with resilient sealing |

Enhance the safety and efficiency of your food processing equipment with KINTEK's precision PTFE components.

Our PTFE-coated O-rings are engineered to meet the stringent demands of the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to ensure a perfect fit for your application.

Contact KINTEK today to discuss how our hygienic sealing solutions can protect your product integrity and streamline your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the recommended tools for CNC machining Teflon? Achieve Clean, Precise Cuts

- How do PTFE gaskets contribute to smooth operation in ball valves? Achieve Low-Friction, Leak-Proof Performance

- Why is PTFE used in electrical components? Unmatched Insulation for Extreme Environments

- What are the main advantages of using PTFE seals? Superior Performance for Demanding Applications

- What overall value do PTFE-free bushings provide? A Strategic Choice for Environmental & Mechanical Performance

- What are the advantages of multi-axis CNC machines for PTFE machining? Achieve Superior Precision for Complex Parts

- How does the flexibility of PTFE expansion bellows compare to metal bellows? A Guide to Superior Movement Absorption

- What are the installation methods for PTFE slide bearings? Select the Right Method for Your Structure