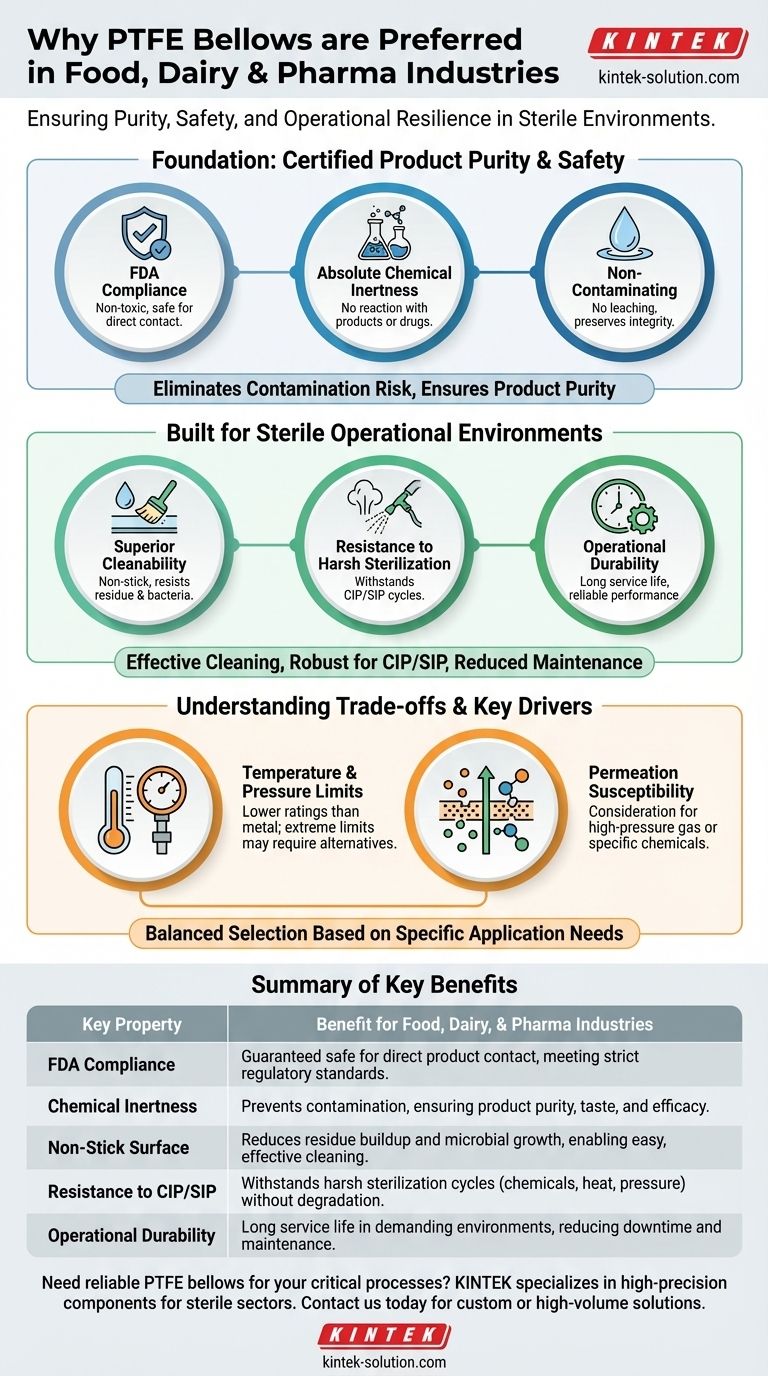

In sterile and sensitive environments, material selection is paramount. PTFE (Polytetrafluoroethylene) bellows are overwhelmingly preferred in the food, dairy, and pharmaceutical industries because they provide a unique combination of certified safety, chemical purity, and operational durability. They are fully compliant with FDA standards, are chemically inert to not contaminate products, and possess non-stick surfaces that allow for easy and effective sterilization.

The preference for PTFE isn't about a single feature; it's about holistically managing risk. These industries demand materials that guarantee product purity, withstand aggressive sterilization protocols, and ensure process integrity, a combination of needs that PTFE is uniquely equipped to meet.

The Foundation: Ensuring Product Purity and Safety

For any material to be considered in food, dairy, or pharmaceutical applications, it must first do no harm. PTFE's fundamental properties make it an ideal candidate for direct and indirect product contact.

FDA Compliance and Biocompatibility

The most critical requirement is regulatory approval. PTFE is available in grades that are fully compliant with FDA standards, making it legally and ethically suitable for use in equipment that processes consumables and medical products. This compliance certifies that the material is non-toxic and safe for its intended application.

Absolute Chemical Inertness

PTFE is one of the most non-reactive materials known. It does not react with the vast majority of chemicals, including sensitive drug compounds, acidic food products, or milk proteins. This chemical inertness ensures that the bellow itself will not alter the composition, taste, or efficacy of the product flowing through it.

Non-Contaminating Properties

Beyond just being inert, PTFE is non-contaminating. It does not leach chemicals or shed particles into the product stream, preserving the absolute purity of the final product. This is a non-negotiable factor in pharmaceutical manufacturing and high-purity food processing.

Built for Sterile Operational Environments

Beyond passive safety, a material must actively support the demanding operational conditions of these industries, particularly the constant need for cleaning and sterilization.

Superior Cleanability and Non-Stick Surface

PTFE is famously known for its non-stick properties. In a processing line, this means that viscous fluids, syrups, and other residues are far less likely to adhere to the bellow's surface. This quality, combined with its resistance to bacterial growth, makes cleaning faster, more effective, and more reliable.

Resistance to Harsh Sterilization

These industries rely on aggressive cleaning regimens, such as Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems. These processes use harsh chemicals, high temperatures, and high pressure to ensure sterility. PTFE's robust chemical and thermal resistance means it can withstand these cycles repeatedly without degrading, ensuring a long and reliable service life.

Understanding the Trade-offs

While PTFE is an exceptional material, a complete technical assessment requires acknowledging its limitations. Understanding these trade-offs is key to proper application and engineering.

Temperature and Pressure Boundaries

Although PTFE has excellent thermal resistance for a polymer, it has a lower maximum operating temperature and pressure rating compared to metal bellows. In systems that experience extreme temperature or pressure spikes beyond PTFE's specified limits, metal alternatives may be necessary.

Susceptibility to Permeation

Certain small-molecule gases and liquids can, over time, permeate through the PTFE material. While this is not an issue for most food and pharma applications, it can be a consideration in high-pressure gas or specific chemical processing scenarios.

Cost and Installation Considerations

PTFE bellows typically represent a higher initial investment compared to some rubber or elastomer alternatives. Furthermore, their rigidity requires careful handling during installation to avoid scratches or mechanical damage that could compromise the surface integrity. This cost is often justified by longevity and reduced contamination risk, but it is a factor in initial project budgeting.

Making the Right Choice for Your Application

Selecting the right bellow material is a decision based on your primary operational driver.

- If your primary focus is uncompromising product purity: PTFE's chemical inertness and FDA compliance make it the default choice to eliminate any risk of product contamination.

- If your primary focus is operational resilience against aggressive cleaning: PTFE's unmatched resistance to harsh sterilization chemicals ensures long service life and consistent performance.

- If your primary focus is preventing microbial growth and residue buildup: The non-stick, hydrophobic surface of PTFE provides the most hygienic and easily cleanable option available.

Ultimately, selecting PTFE bellows is a strategic decision to invest in the absolute integrity of your product and the long-term reliability of your process.

Summary Table:

| Key Property | Benefit for Food, Dairy, & Pharma Industries |

|---|---|

| FDA Compliance | Guaranteed safe for direct product contact, meeting strict regulatory standards. |

| Chemical Inertness | Prevents contamination, ensuring product purity, taste, and efficacy. |

| Non-Stick Surface | Reduces residue buildup and microbial growth, enabling easy, effective cleaning. |

| Resistance to CIP/SIP | Withstands harsh sterilization cycles (chemicals, heat, pressure) without degradation. |

| Operational Durability | Long service life in demanding environments, reducing downtime and maintenance. |

Need reliable PTFE bellows for your critical processes? At KINTEK, we specialize in manufacturing high-precision PTFE components (including seals, liners, and bellows) tailored for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment meets the highest standards of purity and durability. From custom prototypes to high-volume orders, we deliver solutions that protect your product integrity. Contact us today to discuss your specific requirements!

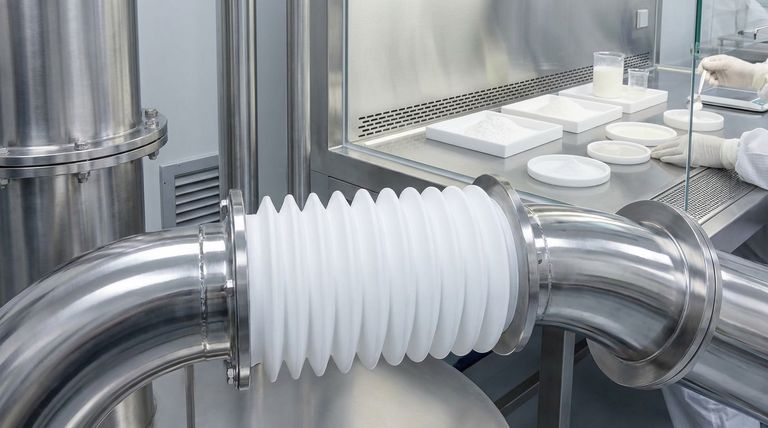

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What role does proactive maintenance play in the lifespan of PTFE Expansion Bellows? Maximize Reliability and Uptime

- What types of fluids can ePTFE gaskets seal effectively? Ensure Leak-Free Performance with Superior Chemical Resistance

- How often should PTFE butterfly valves be maintained? Optimize Your Maintenance Schedule

- How does a pneumatic actuator function in a PTFE pneumatic valve? A Guide to Automated Control

- Why are PTFE liners ideal for handling sticky materials? Maximize Yield and Simplify Cleaning

- What makes PTFE liners suitable for high-temperature applications? Unlock Thermal Resilience for Demanding Processes

- What are the main benefits of using PTFE liners? Achieve Unmatched Chemical and Thermal Resistance

- How does the working process affect PTFE Teflon O-rings? It Dictates Sealing Performance & Lifespan