In short, PTFE balls are preferred for handling corrosive chemicals because their molecular structure makes them almost completely inert. They do not react with or degrade when exposed to nearly all industrial acids, bases, and solvents, ensuring system integrity where other materials like metals or plastics would fail.

The core reason for choosing PTFE is not just its chemical resistance, but its predictable reliability. In applications involving aggressive chemicals, material failure is not an option, and PTFE’s inherent inertness provides the highest level of assurance against corrosion, leaks, and system breakdown.

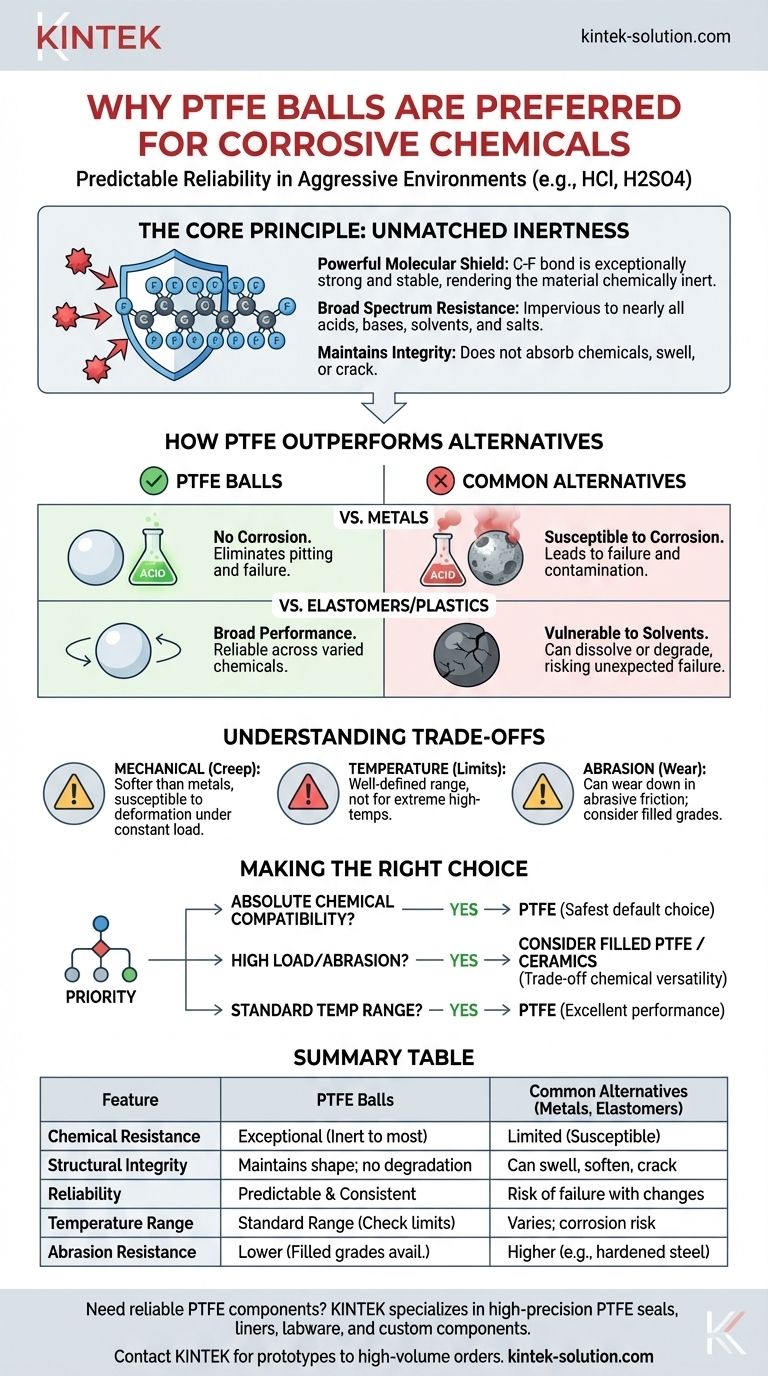

The Core Principle: Unmatched Chemical Inertness

The exceptional performance of Polytetrafluoroethylene (PTFE) stems from its unique chemical makeup, which makes it one of the most non-reactive substances known.

What Makes PTFE So Resistant?

At a molecular level, PTFE consists of a chain of carbon atoms completely shielded by a layer of fluorine atoms. The bond between carbon and fluorine is exceptionally strong and stable.

This powerful molecular shield prevents aggressive chemicals from attacking the underlying carbon chain, rendering the material effectively inert.

A Broad Spectrum of Resistance

This chemical stability means PTFE is impervious to a vast range of corrosive substances. This includes strong acids like sulfuric and hydrochloric acid, potent bases, organic solvents, and salts.

Unlike other materials that may resist some chemicals but not others, PTFE offers consistent and reliable performance across the board.

Maintaining Structural Integrity

True resistance is more than just avoiding corrosion. Many materials, like elastomers (rubbers), can absorb chemicals, causing them to swell, soften, or crack over time.

PTFE does not suffer from this. It maintains its shape, hardness, and structural integrity, ensuring that components like balls in valves or check pumps continue to function as designed without degradation.

How PTFE Outperforms Common Alternatives

When designing systems for corrosive media, engineers often compare PTFE to specialized metals and other polymers. The comparison makes its advantages clear.

The Problem with Metals

Even highly resistant metals like stainless steel can be susceptible to corrosion, especially from specific acids, chlorides, or over long periods of exposure.

This corrosion leads to pitting, component failure, and potential contamination of the process fluid. PTFE eliminates this entire class of failure.

The Failure of Elastomers and Other Plastics

While some elastomers and plastics offer good chemical resistance, few can match the broad-spectrum performance of PTFE.

They are often vulnerable to specific solvents that can cause them to dissolve or degrade. This makes material selection complex and increases the risk of choosing a material that fails unexpectedly if the chemical composition changes.

Understanding the Trade-offs

While its chemical properties are superior, PTFE is not the ideal choice for every single industrial application. Acknowledging its limitations is key to proper system design.

Mechanical Properties

PTFE is a relatively soft material compared to metals or ceramics. In high-pressure applications, it can be susceptible to "creep," or slow deformation under a constant load.

Temperature Limitations

Standard PTFE has a well-defined and useful service temperature range, but it is not suitable for extremely high-temperature environments where specialty metals or ceramics would be required.

Abrasion Resistance

Because it is a softer polymer, PTFE can wear down more quickly than hardened steel or ceramic balls in applications with significant abrasive friction. For these scenarios, filled PTFE grades or alternative materials may be necessary.

Making the Right Choice for Your Application

Selecting the correct material requires balancing chemical resistance with the physical demands of the system.

- If your primary focus is absolute chemical compatibility: PTFE is the safest and most reliable default choice for handling a wide and aggressive range of chemicals.

- If your application involves high mechanical loads or abrasion: Consider filled PTFE grades for improved strength or harder materials like ceramics, but be prepared to trade off some chemical versatility.

- If you are operating in a standard temperature range: PTFE provides excellent performance, but always verify your system's operating temperatures against the material's specific limits.

Ultimately, choosing PTFE for corrosive environments is a decision rooted in prioritizing safety and long-term reliability.

Summary Table:

| Feature | PTFE Balls | Common Alternatives (Metals, Elastomers) |

|---|---|---|

| Chemical Resistance | Exceptional (inert to most acids, bases, solvents) | Limited (susceptible to corrosion, swelling) |

| Structural Integrity | Maintains shape and hardness; no degradation | Can swell, soften, or crack over time |

| Reliability | Predictable and consistent performance | Risk of failure with chemical changes |

| Temperature Range | Standard range (check specific limits) | Varies; may handle higher temps but with corrosion risk |

| Abrasion Resistance | Lower (softer material); filled grades available | Higher (e.g., hardened steel) but less chemically resistant |

Need reliable PTFE components for your corrosive chemical applications? KINTEK specializes in manufacturing high-precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your systems maintain integrity and safety with materials that withstand aggressive environments. Contact us today to discuss your project requirements—from prototypes to high-volume orders—and benefit from our commitment to precision and durability.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the common applications of PTFE balls? Leverage Unmatched Chemical Resistance & Low Friction

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained

- What size range do PTFE balls come in? A Guide from 3mm to 100mm

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites