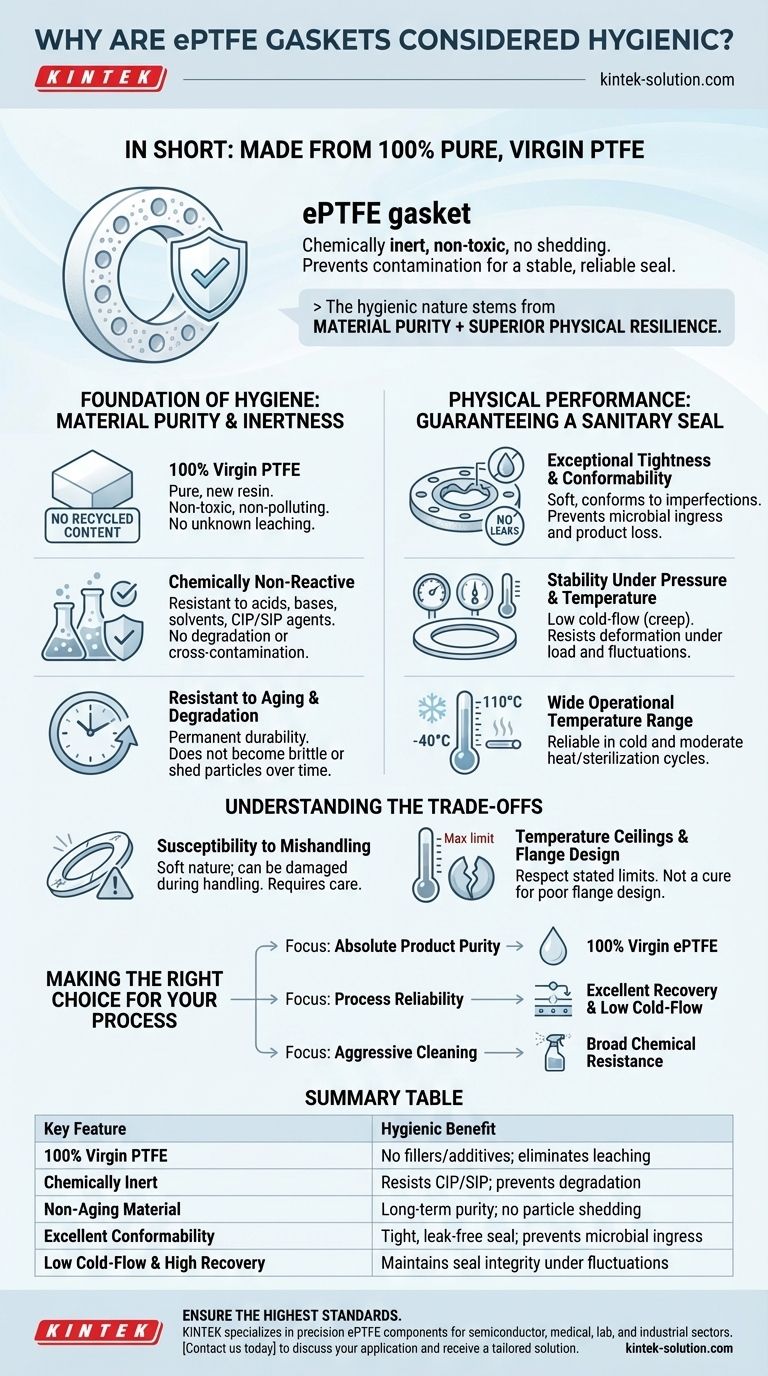

In short, ePTFE gaskets are considered hygienic because they are made from 100% pure, virgin Polytetrafluoroethylene (PTFE). This material is chemically inert, non-toxic, and does not degrade or shed particles into the process stream, preventing product contamination and ensuring a stable, reliable seal in sensitive environments.

The hygienic nature of an ePTFE gasket stems from a crucial combination: its inherent material purity, which prevents it from contaminating the product, and its superior physical resilience, which ensures the seal remains intact and leak-free under demanding process conditions.

The Foundation of Hygiene: Material Purity and Inertness

A material's suitability for hygienic applications begins with its fundamental composition. ePTFE excels because it is designed to be fundamentally non-interactive with its environment.

Made from 100% Virgin PTFE

The term "virgin" is critical. It means the gasket is made from pure, new PTFE resin with no recycled content, fillers, or additives. This eliminates the risk of unknown substances leaching into the product.

This purity makes the material non-toxic and non-polluting, ensuring it is harmless when in direct contact with food, beverages, or pharmaceutical compounds.

Chemically Non-Reactive

ePTFE inherits PTFE's exceptional chemical stability. It is resistant to a vast range of substances, including acids, bases, alkalis, solvents, and aggressive cleaning agents used in Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems.

This inertness ensures the gasket will not degrade, swell, or react with the process media, which prevents cross-contamination and maintains product integrity.

Resistant to Aging and Degradation

Unlike many elastomers or plastics, ePTFE does not age or become brittle over its operational lifespan. It offers permanent durability, meaning it won't break down and release particles into the system over time, a critical factor for maintaining a sanitary environment.

How Physical Performance Guarantees a Sanitary Seal

Material purity alone is not enough. A hygienic gasket must also create and maintain a perfect physical barrier between the process and the outside world.

Exceptional Tightness and Conformability

ePTFE is soft and can conform to fill in wide or irregular gaps and imperfections on flange surfaces. This creates an extremely tight seal that prevents leaks, which are a primary pathway for microbial ingress and product loss.

Stability Under Pressure and Temperature

A key advantage of ePTFE is its very low cold-flow (or creep) tendency. It resists deforming permanently under load, even with fluctuations in pressure and temperature.

Combined with excellent recovery properties, this means the seal remains tight and effective through various process cycles, preventing the momentary breaches that could compromise sterility.

Wide Operational Temperature Range

ePTFE gaskets can reliably operate in a range of temperatures, typically from -40°C to 110°C (-40°F to 230°F), accommodating both cold processing and moderate heat or sterilization cycles without losing sealing integrity.

Understanding the Trade-offs

While ePTFE is an exceptional hygienic material, no solution is perfect for every scenario. An objective assessment requires acknowledging its limitations.

Susceptibility to Mishandling

While mechanically resilient in-service, the soft nature of ePTFE means it can be scratched or damaged during handling and installation. A damaged surface can compromise the seal and create a potential harbourage point for bacteria.

Temperature Ceilings

The stated temperature limits must be respected. While suitable for many applications, ePTFE may not be the right choice for high-temperature steam or other processes that consistently exceed its specified maximum operating temperature. Always verify the manufacturer's data for your specific grade.

Not a Cure for Poor Flange Design

ePTFE’s conformability is a major benefit, but it cannot fully compensate for severely damaged or poorly designed flange surfaces. A successful hygienic seal depends on both the gasket material and the mechanical integrity of the equipment itself.

Making the Right Choice for Your Process

Selecting a gasket requires matching its properties to your primary operational goal.

- If your primary focus is absolute product purity: The non-toxic, chemically inert, and non-aging properties of 100% virgin ePTFE make it an ideal choice.

- If your primary focus is process reliability under fluctuating conditions: Its excellent recovery and low cold-flow ensure a durable, leak-free seal through pressure and temperature cycles.

- If your primary focus is withstanding aggressive cleaning protocols: ePTFE's broad chemical resistance ensures it will not degrade from exposure to the caustics and acids used in CIP/SIP systems.

Ultimately, choosing ePTFE is an investment in a sealing solution that provides both safety and unwavering performance.

Summary Table:

| Key Feature | Hygienic Benefit |

|---|---|

| 100% Virgin PTFE | No fillers or additives; eliminates risk of leaching and contamination |

| Chemically Inert | Resists acids, bases, solvents, and CIP/SIP chemicals; prevents degradation |

| Non-Aging Material | Does not become brittle or shed particles over time, ensuring long-term purity |

| Excellent Conformability | Creates a tight, leak-free seal to prevent microbial ingress |

| Low Cold-Flow & High Recovery | Maintains seal integrity under pressure/temperature fluctuations for process reliability |

Ensure the highest standards of hygiene and reliability in your process.

At KINTEK, we specialize in manufacturing precision ePTFE components—including seals, gaskets, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our 100% virgin ePTFE gaskets are engineered to provide a contaminant-free seal that withstands aggressive cleaning protocols and variable operating conditions.

Whether you need a custom prototype or high-volume production, we deliver solutions that prioritize your product's purity and operational safety.

Contact us today to discuss your specific application requirements and receive a tailored solution from KINTEK.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications