Envelope gaskets earn their name from their unique, composite construction. They consist of a soft, compressible core material, or "insert," that is completely wrapped—or enclosed—within an outer jacket, or "envelope," of Polytetrafluoroethylene (PTFE). This design is why they are interchangeably called encased, enclosed, or jacketed gaskets.

The term "envelope" is not just a name; it describes the gasket's fundamental design principle. This structure strategically combines the superior chemical resistance of a PTFE outer layer with the mechanical resilience and sealing force of a separate inner core material.

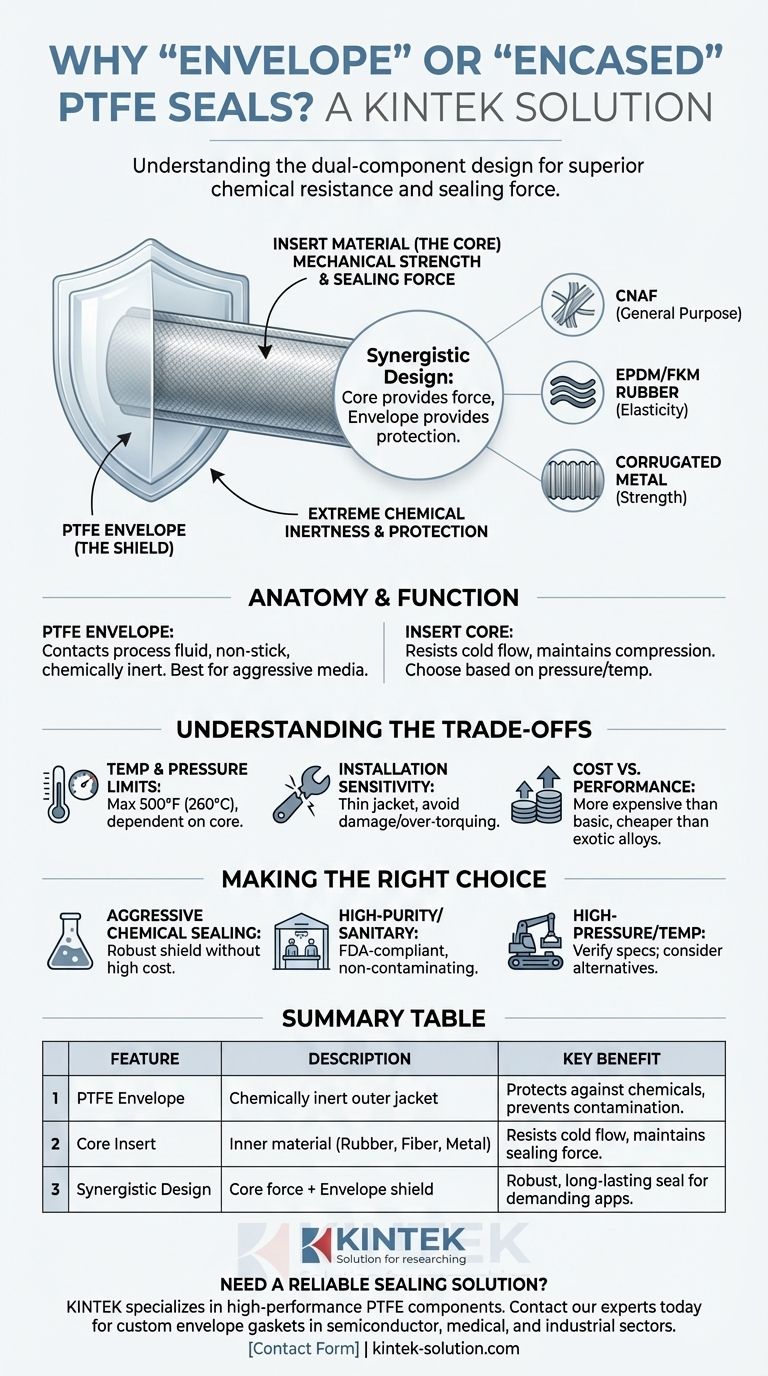

Anatomy of an Envelope Gasket

To understand why this design is so effective, you must look at its two distinct components and the roles they play. The gasket is a synergy of a protective shield and a structural core.

The PTFE Envelope (The Shield)

The outer jacket is the "envelope" itself. It is made from PTFE (best known by the brand name Teflon™) for one primary reason: extreme chemical inertness.

This PTFE layer is the only part of the gasket that comes into contact with the process fluid. Its properties provide a non-stick, non-contaminating surface that can withstand nearly all industrial chemicals, solvents, and corrosive agents.

The Insert Material (The Core)

Pure, solid PTFE has a significant drawback: under the compressive load of a bolted flange, it is susceptible to cold flow, or creep. It deforms permanently and loses its sealing pressure over time.

The inner core, or "insert," solves this problem. This core provides the mechanical strength, compressibility, and recovery needed to maintain a tight seal. Common insert materials include:

- Compressed Non-Asbestos Fiber (CNAF): A good general-purpose choice.

- EPDM or FKM Rubber: Offers excellent elasticity and recovery for lower-pressure applications.

- Corrugated Metal: Provides superior strength and resilience for higher pressures and temperatures.

How They Work Together

The design is simple but brilliant. The core provides the robust mechanical force needed to create and maintain the seal. The PTFE envelope protects this core from chemical attack, ensuring the gasket's longevity and preventing product contamination.

Understanding the Trade-offs

While highly effective, envelope gaskets are not a universal solution. Understanding their limitations is key to using them correctly.

Temperature and Pressure Limitations

The service limits of an envelope gasket are dictated by its weakest component. While a metal core can handle high temperatures, the PTFE envelope itself typically has a maximum service temperature of around 500°F (260°C). Pressure ratings are also dependent on both the core material and flange design.

Installation Sensitivity

The PTFE jacket is relatively thin and can be damaged during installation. Scratches or gouges on the gasket surface from rough flange faces can create a leak path. Likewise, extreme over-torquing can damage the envelope and cause premature failure.

Cost vs. Performance

Envelope gaskets are generally more expensive than simple elastomeric or fiber gaskets. However, they are often a much more cost-effective solution than gaskets made from exotic alloys when sealing highly aggressive media.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching its capabilities to your operational demands.

- If your primary focus is aggressive chemical sealing: An envelope gasket is an excellent choice, providing a robust chemical shield without the high cost of a solid exotic alloy gasket.

- If your primary focus is high-purity or sanitary processes: The non-contaminating, FDA-compliant surface of the PTFE envelope makes this gasket type ideal for food, beverage, and pharmaceutical applications.

- If your primary focus is high-pressure or high-temperature service: You must carefully verify the gasket's specifications, as a spiral wound or solid metal gasket may be more appropriate beyond the limits of the chosen envelope and core materials.

By understanding this "enclosed" design, you can leverage the unique strengths of two different materials in a single, highly effective sealing solution.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| PTFE Envelope | Outer jacket made of chemically inert PTFE. | Protects against aggressive chemicals and prevents contamination. |

| Core Insert | Inner material (e.g., rubber, fiber, metal) providing mechanical strength. | Resists cold flow, maintains sealing force under compression. |

| Synergistic Design | The core provides the sealing force; the envelope provides the chemical shield. | Creates a robust, long-lasting seal for demanding applications. |

Need a reliable sealing solution for aggressive chemicals or high-purity processes?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets. Our seals are engineered for precision and durability, protecting your equipment in the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact seal your application demands.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key features of TFE Encapsulated O-Rings and Gaskets? Achieve Superior Sealing in Demanding Environments

- How is glass-filled PTFE used in construction? Enhance Structural Integrity & Durability

- What is PV value and why is it important for PTFE seals? Prevent Premature Seal Failure

- How is PTFE processed into usable shapes? From Powder to Precision Parts

- What is the role of Teflon backup rings in sealing technology? Prevent Seal Extrusion & Boost Reliability

- How does CNC turning work for PTFE, and what precautions are necessary? Achieve Precision Machining

- How do PTFE slide bearings accommodate thermal and seismic movements? Control Structural Movement with Low-Friction Design

- What are the applications of PTFE chevron packing in the aerospace industry? Ensure Reliability in Extreme Conditions