For standard industrial applications, the best contact surface for PTFE piston rings is fine-laminar gray cast iron. It provides a durable and cost-effective solution with excellent wear characteristics. However, in applications involving corrosion or requiring higher performance, materials like high-alloyed chrome steels, hard-anodized aluminum, or Nikasil coatings are the superior choice.

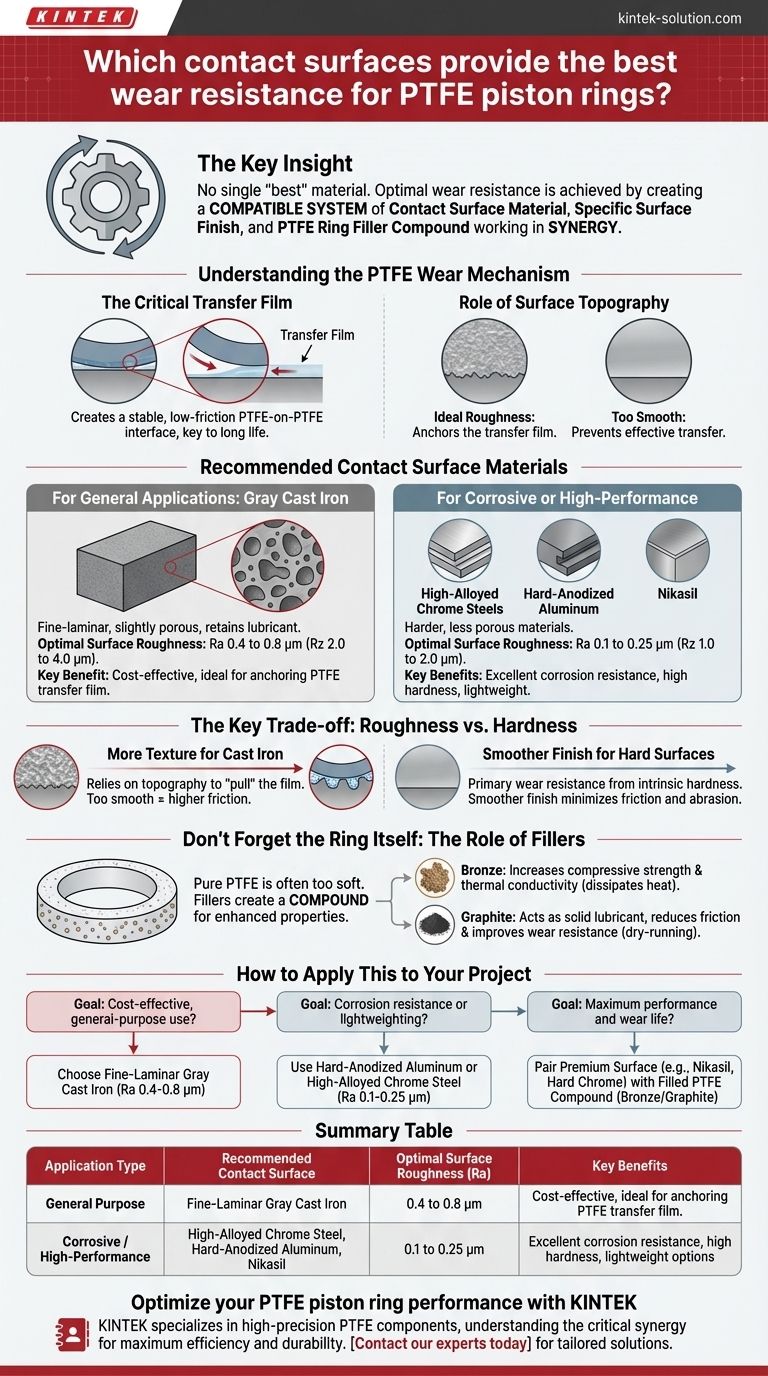

The optimal wear resistance for a PTFE piston ring is not achieved by selecting a single "best" material, but by creating a compatible system where the contact surface material, its specific surface finish, and the PTFE ring's filler compound all work in synergy.

Understanding the PTFE Wear Mechanism

To select the right surface, you must first understand how PTFE functions. It's not just about being slippery; it's about creating a new, optimized surface during operation.

The Critical Transfer Film

PTFE's low-friction properties are fully realized only after a very thin layer of the PTFE material is transferred from the ring to the mating contact surface. This "transfer film" creates a stable, low-friction PTFE-on-PTFE interface, which is the key to long life and low wear.

The Role of Surface Topography

The microscopic texture, or roughness, of the contact surface is critical. It must be rough enough to help establish and anchor the initial transfer film but smooth enough to prevent abrasive wear on the ring itself. The ideal roughness is not universal; it depends entirely on the chosen surface material.

Recommended Contact Surface Materials

The choice of material is primarily driven by the operating environment and performance requirements of the application.

For General Applications: Gray Cast Iron

Fine-laminar gray cast iron is the go-to material for many hydraulic and pneumatic cylinders. Its slightly porous microstructure helps retain lubricant and provides ideal "pockets" for the PTFE transfer film to anchor securely.

For this material, the optimal surface roughness is Ra 0.4 to 0.8 µm (Rz 2.0 to 4.0 µm).

For Corrosive or High-Performance Applications

When dealing with moisture, chemicals, or the need for lighter weight, alternative materials are necessary. These are typically harder and less porous than cast iron.

- High-Alloyed Chrome Steels: These materials offer excellent hardness and inherent corrosion resistance, making them ideal for demanding environments.

- Hard-Anodized Aluminum: This provides a very hard, corrosion-resistant surface on a lightweight aluminum base, perfect for applications where weight is a primary concern.

- Nikasil: This is a nickel-silicon carbide plating applied to a base metal (often aluminum). It creates an extremely hard and durable surface with exceptional wear resistance for the most demanding applications.

For these harder, denser materials, a much smoother finish is required: Ra 0.1 to 0.25 µm (Rz 1.0 to 2.0 µm).

The Key Trade-off: Roughness vs. Hardness

The most common point of failure in system design is misunderstanding the relationship between a material's hardness and its required surface finish.

Why Gray Cast Iron Needs More Texture

Cast iron relies on its specific topography to "pull" the initial PTFE film from the ring and create the low-friction interface. If the surface is polished too smoothly, the film cannot transfer effectively, leading to higher friction and accelerated wear.

Why Hard Surfaces Require a Smoother Finish

Extremely hard materials like chrome steel or Nikasil do not rely on mechanical anchoring for the transfer film in the same way. Their primary wear resistance comes from their intrinsic hardness, which prevents the surface from being scratched or abraded. A smoother finish minimizes friction from the start and prevents the hard surface from acting like a file against the softer PTFE ring.

Don't Forget the Ring Itself: The Role of Fillers

The contact surface is only half of the equation. Pure PTFE is often too soft for demanding applications. Its wear resistance is dramatically improved by adding fillers to create a PTFE compound.

Enhancing Performance with Compounds

Fillers are mixed with the base PTFE resin to enhance specific properties.

- Bronze: Increases compressive strength and thermal conductivity, helping to dissipate heat from the contact zone.

- Graphite: Acts as a solid lubricant, further reducing friction and improving wear resistance, especially in dry-running applications.

Choosing a ring made from a filled compound is just as important as choosing the right mating surface.

How to Apply This to Your Project

Make your selection based on a holistic view of your system's goals and operating environment.

- If your primary focus is cost-effective, general-purpose use: Choose fine-laminar gray cast iron machined to a surface roughness of Ra 0.4 to 0.8 µm.

- If your primary focus is corrosion resistance or lightweighting: Use hard-anodized aluminum or high-alloyed chrome steel, ensuring a much smoother finish of Ra 0.1 to 0.25 µm.

- If your primary focus is maximum performance and wear life: Pair a premium surface like Nikasil or hard chrome plating with a filled PTFE compound containing bronze or graphite.

Achieving maximum wear resistance comes from designing a compatible system, not just selecting a single high-performance part.

Summary Table:

| Application Type | Recommended Contact Surface | Optimal Surface Roughness (Ra) | Key Benefits |

|---|---|---|---|

| General Purpose | Fine-Laminar Gray Cast Iron | 0.4 to 0.8 µm | Cost-effective, ideal for anchoring PTFE transfer film |

| Corrosive / High-Performance | High-Alloyed Chrome Steel, Hard-Anodized Aluminum, Nikasil | 0.1 to 0.25 µm | Excellent corrosion resistance, high hardness, lightweight options |

Optimize your PTFE piston ring performance with KINTEK.

Selecting the right contact surface is critical for wear resistance and longevity. At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom piston rings. We understand the critical synergy between the ring's compound and the mating surface.

Whether you need a standard solution for industrial applications or a custom-fabricated part for the semiconductor, medical, or laboratory industries, we can help. Our expertise ensures your system is designed for maximum efficiency and durability, from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and get a solution tailored for peak performance.

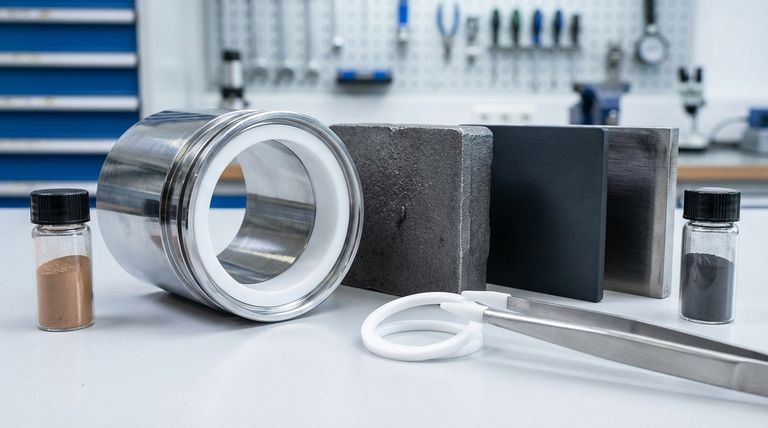

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key characteristics of Teflon seals? Unmatched Chemical & Temperature Resistance

- What are the tolerance specifications for the thickness of PTFE disks? Why ±20% is the Industry Standard

- What industries commonly use PTFE rotary shaft seals? The Ultimate Guide for Extreme Conditions

- What are the key steps in PTFE coating application? A Guide to the Critical 4-Stage Process

- In what ways are extruded PTFE rods utilized in aerospace and automotive industries? Enhancing Performance in Extreme Conditions

- Why is high-quality PTFE more expensive? The Critical Role of Purity and Precision Manufacturing

- What are PTFE seals commonly known as? Discover Teflon® Seals for Extreme Performance

- What temperature range can PTFE flange gaskets withstand? From Cryogenic -200°C to High-Temp +260°C